A device for actively controlling trailing edge winglets with large forward ratio rotor blade anti-stall

A technology of rotor blades and active control, applied in the field of helicopter rotors, can solve the problems of inability to adapt to high-speed helicopters, increased resistance of backward blades, and reduced cruising efficiency, and achieves the effect of alleviating the aerodynamic problem of reverse flow and controlling the reverse flow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

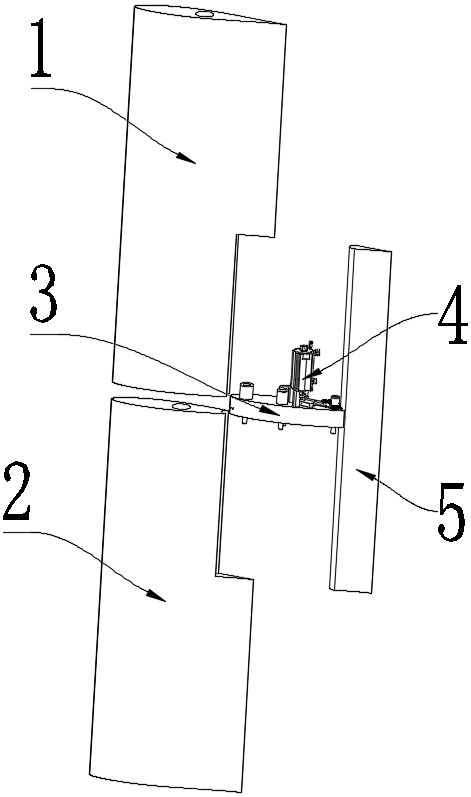

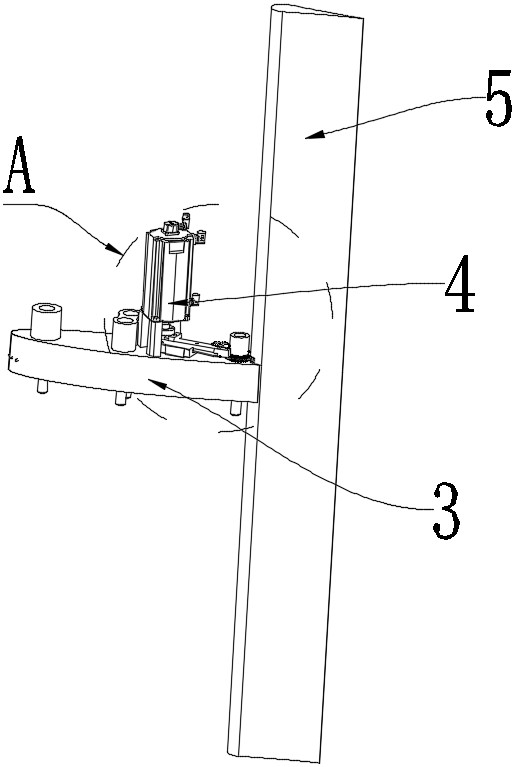

[0025] Example 1: See Figure 1 to Figure 4 , a large forward ratio rotor blade anti-stall active control trailing edge winglet device of the present embodiment comprises a main rotor and an anti-arc winglet 5 arranged on the trailing edge of the main rotor, and a transmission device 4 arranged inside the main rotor , the transmission device 4 is used to drive the anti-arc winglet 5 to do sinusoidal oscillating motion; the main rotor includes a motor 41, an eccentric wheel, a reciprocating slider 44 and a transmission gear set, and the motor 41 drives the eccentric wheel to rotate, and then drives the reciprocating slider 44 to make a straight line Reciprocating motion, the end of the reciprocating slider 44 away from the eccentric wheel is provided with a rack, the rack is engaged with the transmission gear set, the anti-arc winglet 5 is provided with a winglet gear 47 engaged with the transmission gear set, and the rack drives the transmission gear set Rotate, and then drive...

Embodiment 2

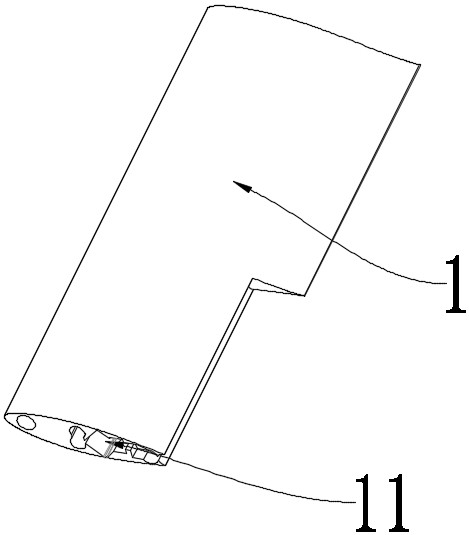

[0026] Embodiment 2: The transmission device 4 of this embodiment is arranged inside the main rotor. The main rotor includes a detachably connected first end portion 1 and a first clamping portion 3. The first clamping portion 3 is close to the first end portion 1. One side is provided with a reciprocating slide rail 43 for the reciprocating slider 44 to move, and the side of the first end 1 close to the first engaging part 3 is provided with an accommodating cavity 11 for accommodating the transmission device 4 . In this embodiment, the side of the first engaging portion 3 away from the first end portion 1 is provided with a second end portion 2 , and the second end portion 2 , the first end portion 1 and the first engaging portion 3 are detachably connected. In this embodiment, a plurality of first fixing holes are provided on the first clamping part 3, and a plurality of second fixing holes are provided on the first end part 1 corresponding to the first fixing holes, and a p...

Embodiment 3

[0027]Embodiment 3: The eccentric wheel of this embodiment includes an eccentric pin and a flange 42, the center of the flange 42 is provided with a rotating hole for connecting the output shaft of the motor 41, and the flange 42 is provided with a rotating hole around the rotating hole for inserting The eccentric pins are connected to a plurality of positioning holes, and the eccentric pins are clamped on the reciprocating slider 44. One end of the reciprocating slider 44 connected to the eccentric pin in this embodiment is provided with a second clamping part, and a transverse groove is arranged on the second clamping part, and the width of the transverse groove is slightly larger than the diameter of the eccentric pin to accommodate the eccentric pin. The pin slides in the groove, driving the reciprocating slider 44 to reciprocate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com