Sealing leakproof flange

An anti-leakage and flange technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problem of flanges without anti-leakage and other problems, and achieve the effect of good sealing and anti-leakage function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

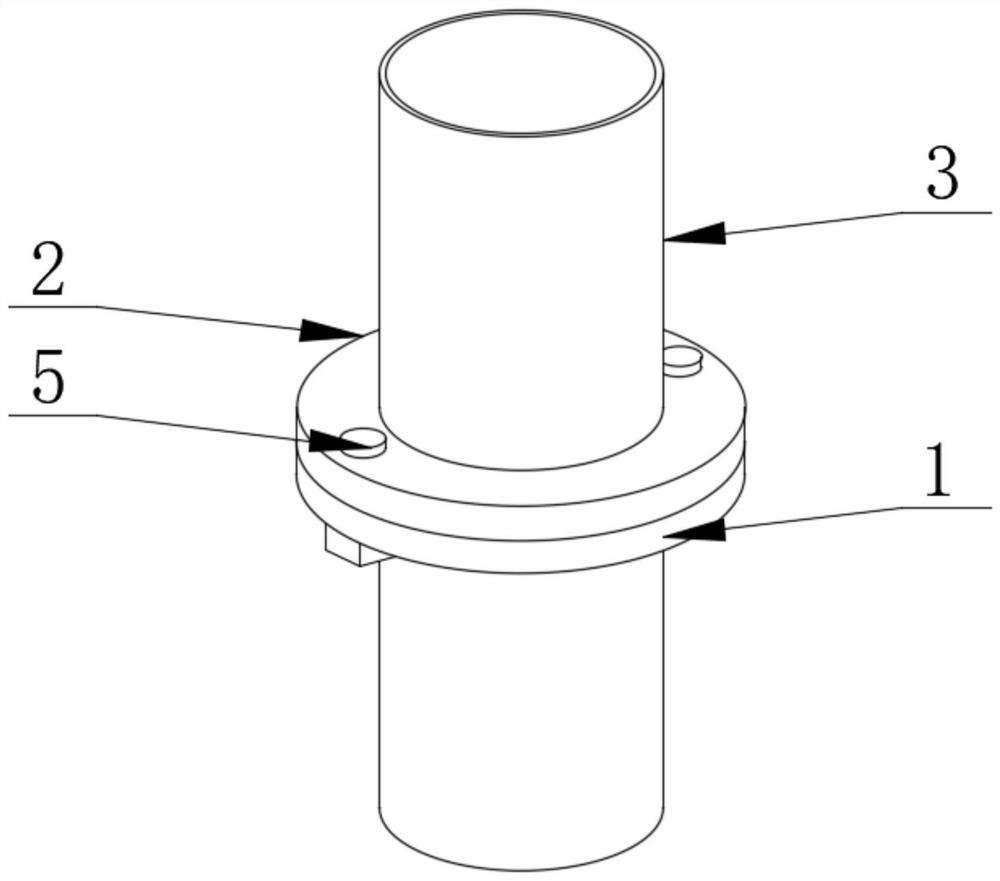

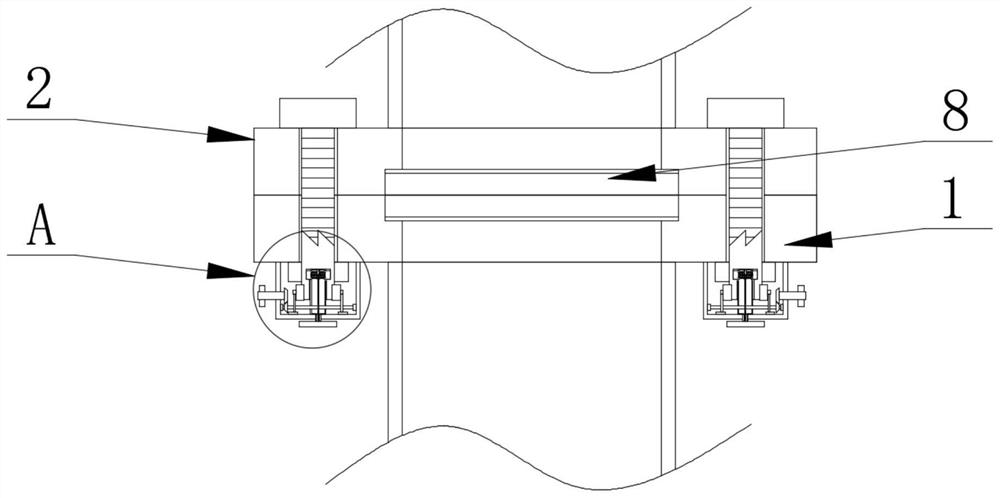

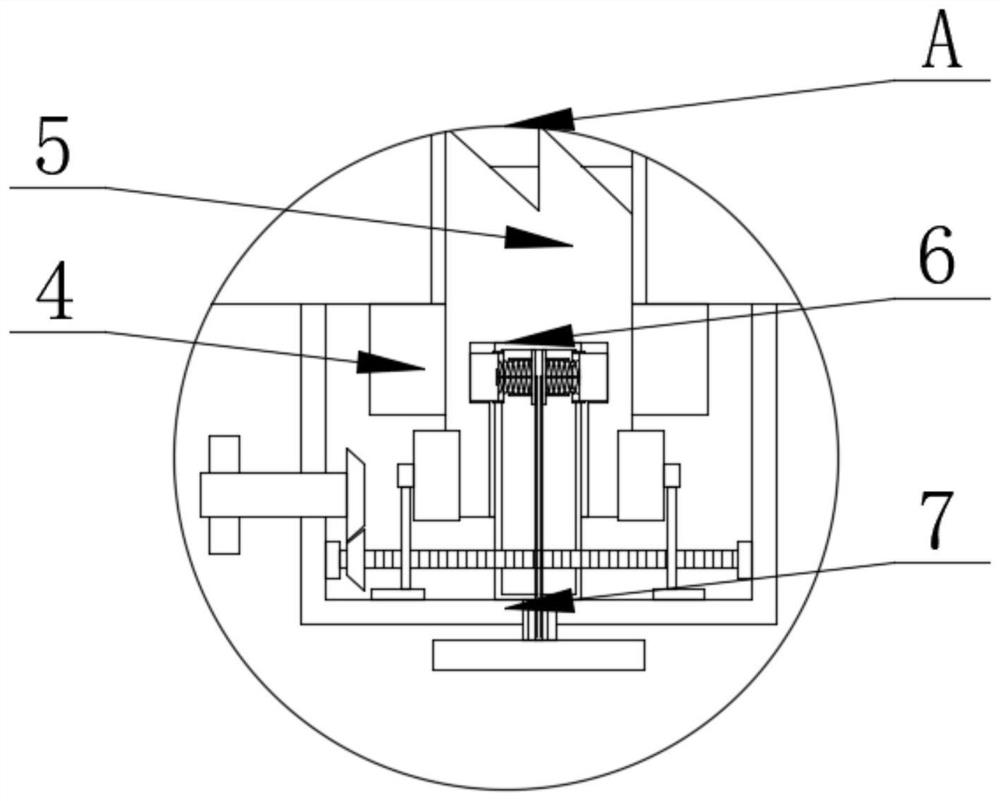

[0027] see Figure 1-9 , in an embodiment of the present invention, a leak-proof flange includes a first flange piece 1 and a second flange piece 2, and pipes are installed at one end of the first flange piece 1 and the second flange piece 2 3. The left and right sides of the lower surface of the first flange piece 1 are fixedly connected with nuts 4, the left and right ends of the second flange piece 2 are connected with bolts 5, and the bolts 5 move through the first flange piece 1, And the lower end of the bolt 5 is meshed and connected inside the nut 4, the lower end of the bolt 5 is provided with a positioning groove 6 inside, and the left and right sides of the lower surface of the first flange piece 1 are all provided with a fixing assembly 7 outside the nut 4. 7 includes a fixed seat 9, the fixed seat 9 is fixedly connected on the lower surface of the first flange piece 1, the left side surface of the fixed seat 9 near the lower end position is penetrated and rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com