Full-sea-depth working high-frequency arc-shaped transmitting array

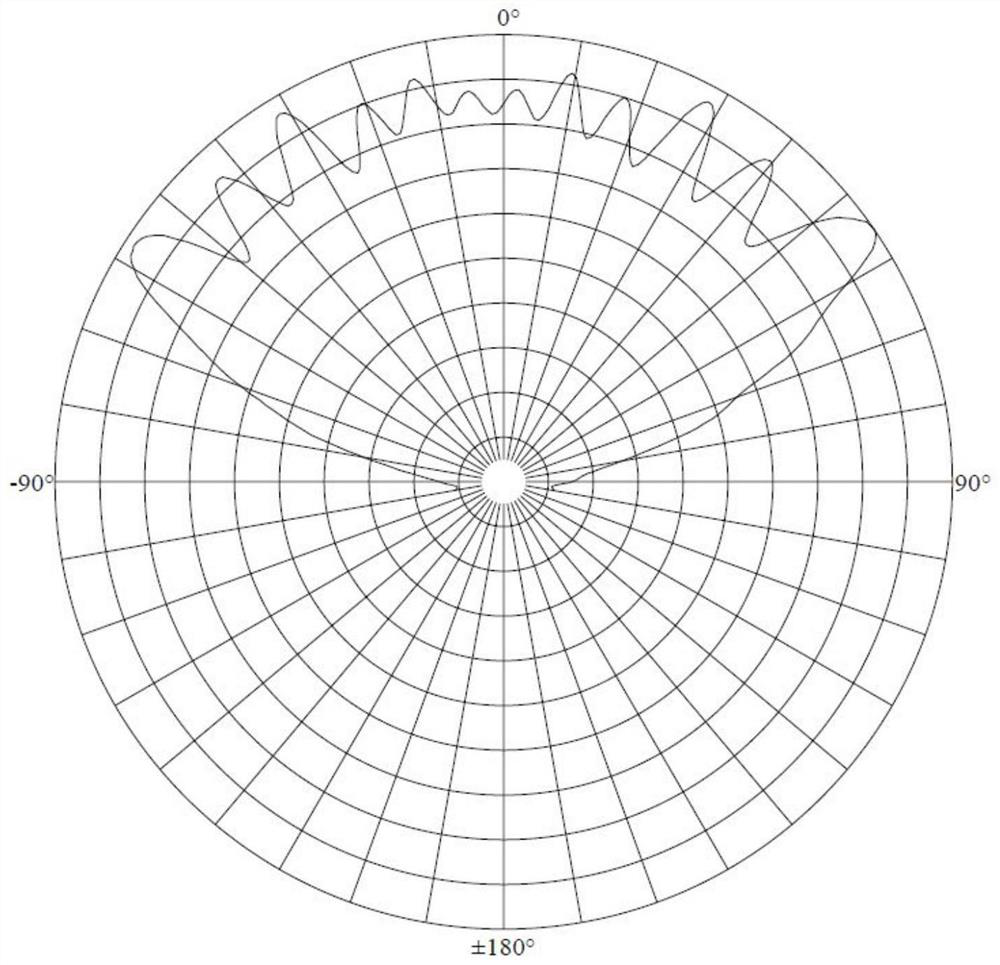

A basic array and arc-shaped technology, which is applied in the field of high-frequency arc-shaped launch arrays working in the full sea depth, can solve the problems of heavy equipment weight and difficulty in meeting the requirements of full-sea deep work, and achieve wide coverage angle and horizontal directivity wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment:

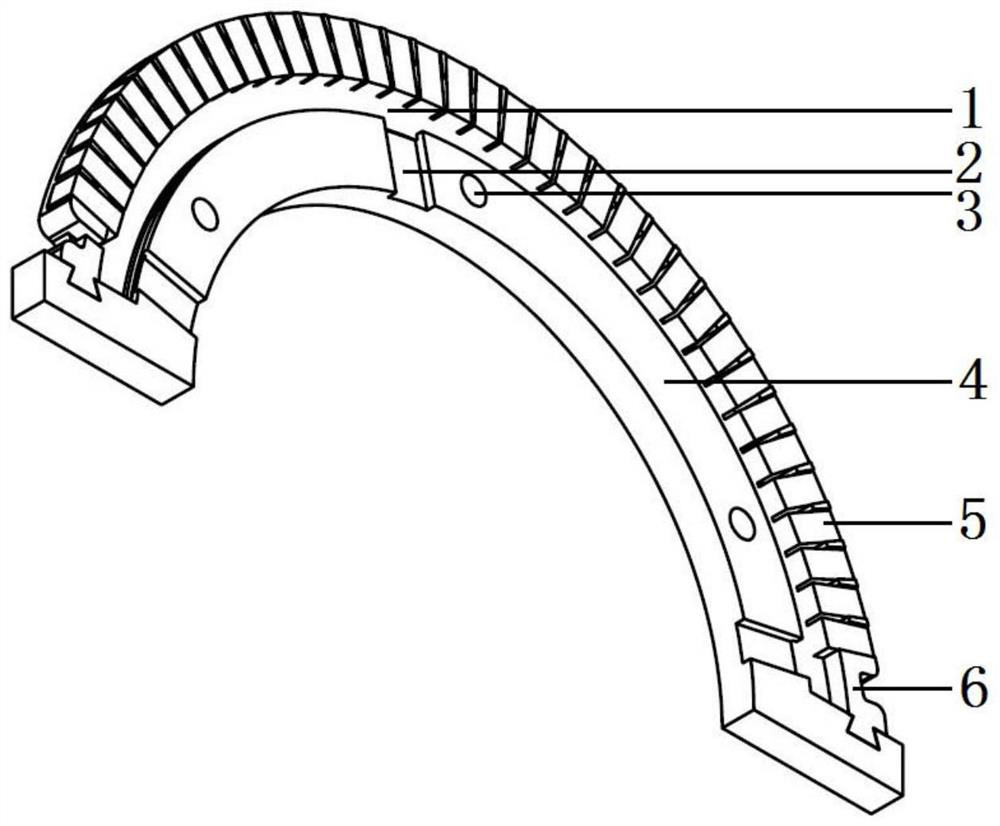

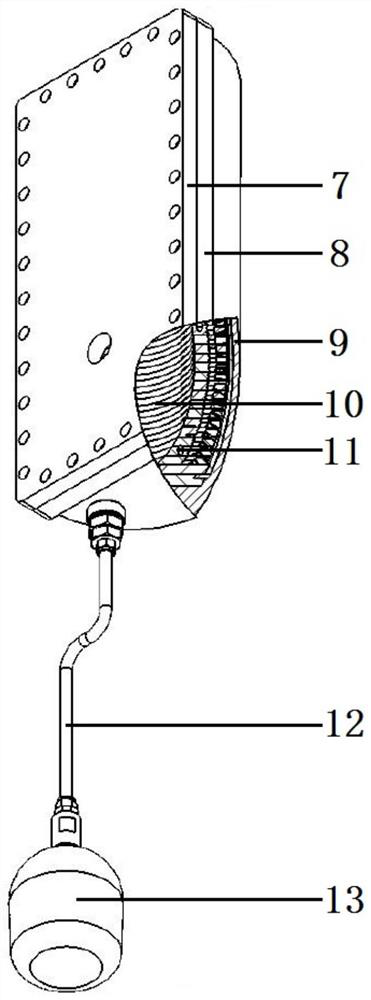

[0021] Such as figure 2 As shown, a full-sea deep-working high-frequency arc-shaped launch array includes a base array metal back cover 7, a base array metal frame 8, a waterproof sound-permeable layer 9, a base array oil-filled chamber 10, and several arc-shaped launch arrays. Unit 11, oil guide pipe 12 and rubber oil bag 13, several arc-shaped emitting units 11 are combined into an arc-shaped emitting unit array through the emitting unit positioning hole 3 and closely matched positioning rods, and all the emitting units in several arc-shaped emitting units 11 The unit oscillators 5 are electrically connected in parallel through wires. The arc-shaped emitting unit array is installed on the metal rear cover 7 of the basic array and is poured with polyurethane to form a waterproof sound-permeable layer 9. The metal rear cover 7 of the basic array and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com