Linearity loudspeaker system high tone horn

A high-pitched horn and loudspeaker technology, which is applied to microphones, loudspeakers, sensors, etc., can solve the problems of uncontrollable product consistency, unsatisfactory frequency response, and high manufacturing cost, so as to improve the efficiency of sound energy utilization and the uniformity of sound pressure The effect of improving and controlling manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

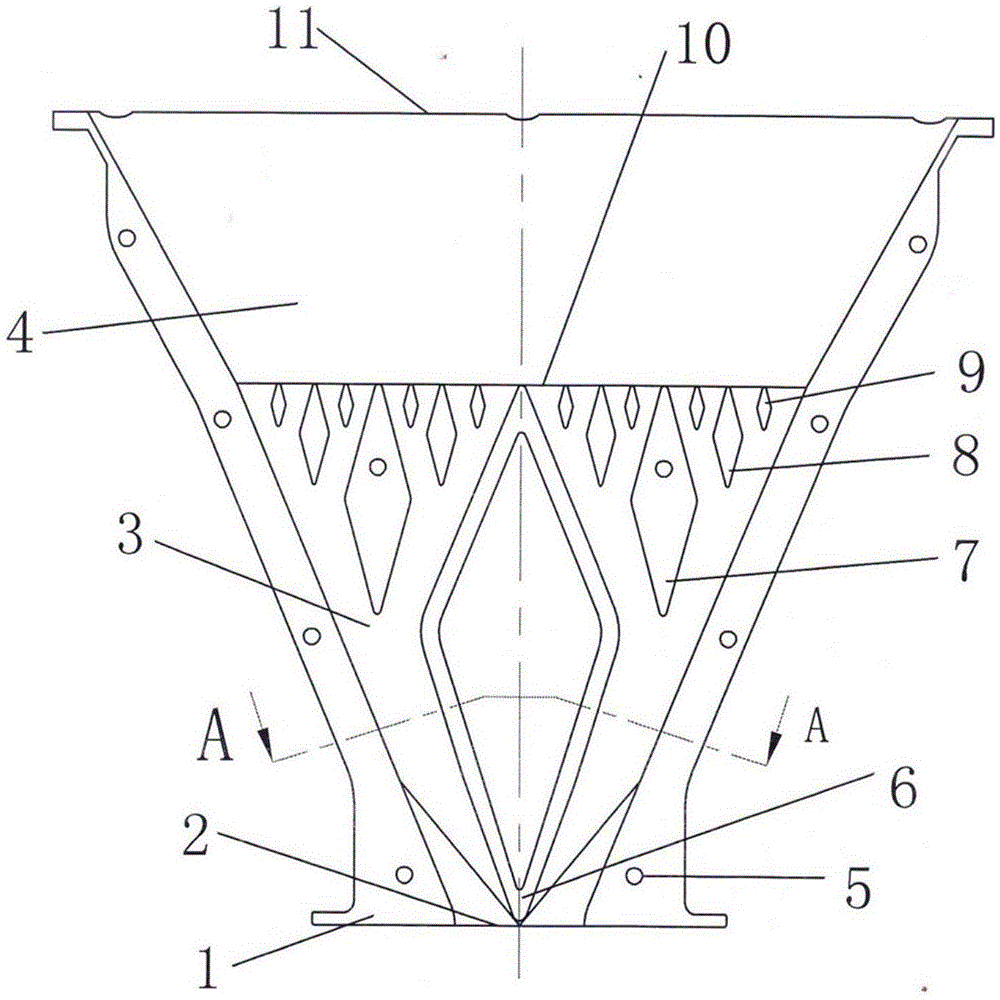

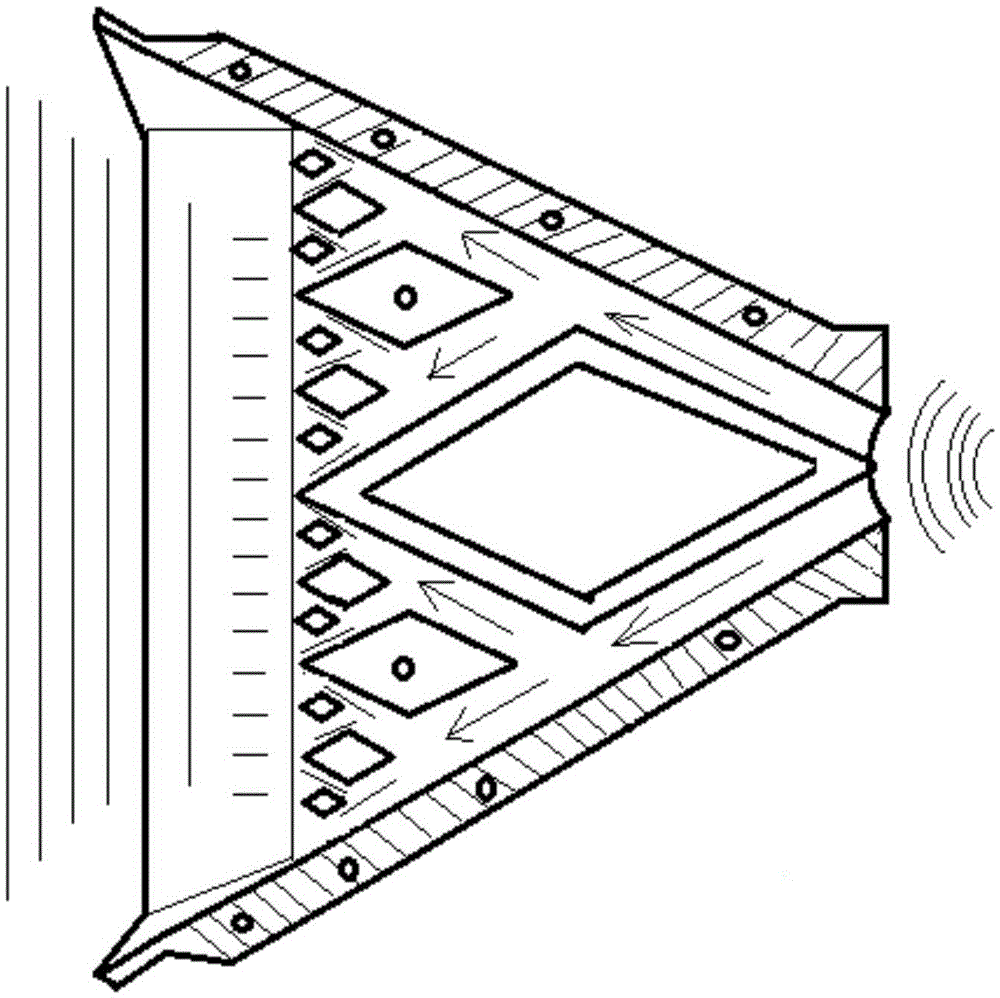

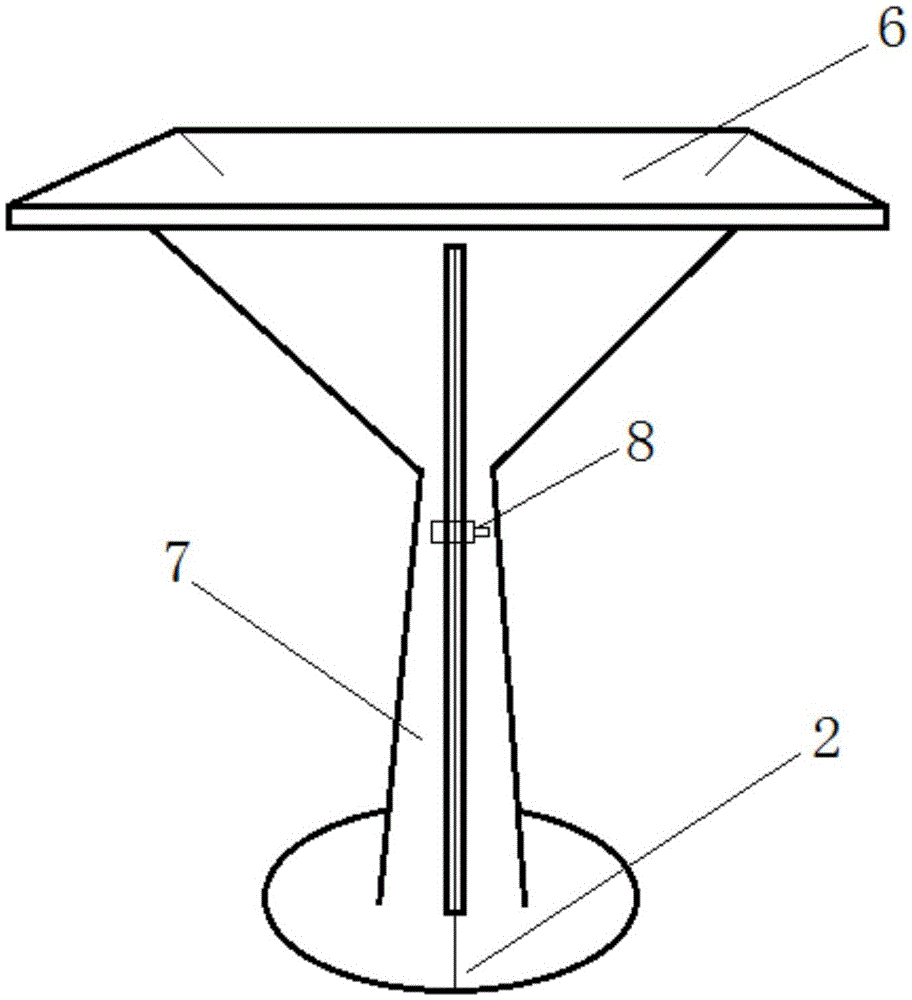

[0027] like figure 1 , 2 As shown, a tweeter horn for a linear speaker system is characterized in that it includes a horn body 1, a throat 2 arranged at the sound entrance of the horn body 1, an acoustic lens 3 arranged inside the horn body 1, and a sound horn arranged at the horn body 1. The diffuse horn 4 at the outlet end and the first-level shunt structure 6, the second-level shunt structure 7, the third-level shunt structure 8, and the fourth-level shunt structure 9 arranged on the acoustic lens 3, the horn body 1 is provided with multiple Screw holes 5, the horn body 1 is two symmetrical semi-cavity structures, the two symmetrical cavity structures are connected by screws passing through the screw holes 5 to form the whole horn.

[0028] In this embodiment, the paths of the first-stage flow distribution structure 6 , the second-stage flow distribution structure 7 , the third-stage flow distribution structure 8 , and the fourth-stage flow distribution structure 9 are equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com