Manual clutch

A clutch, manual technology, applied in clutches, mechanically driven clutches, clutches that mesh with each other, etc., can solve the problems of complex installation structure, inconvenient disassembly, maintenance, and high production costs of clutches, and achieve low cost, reduced friction, and reduced wear degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

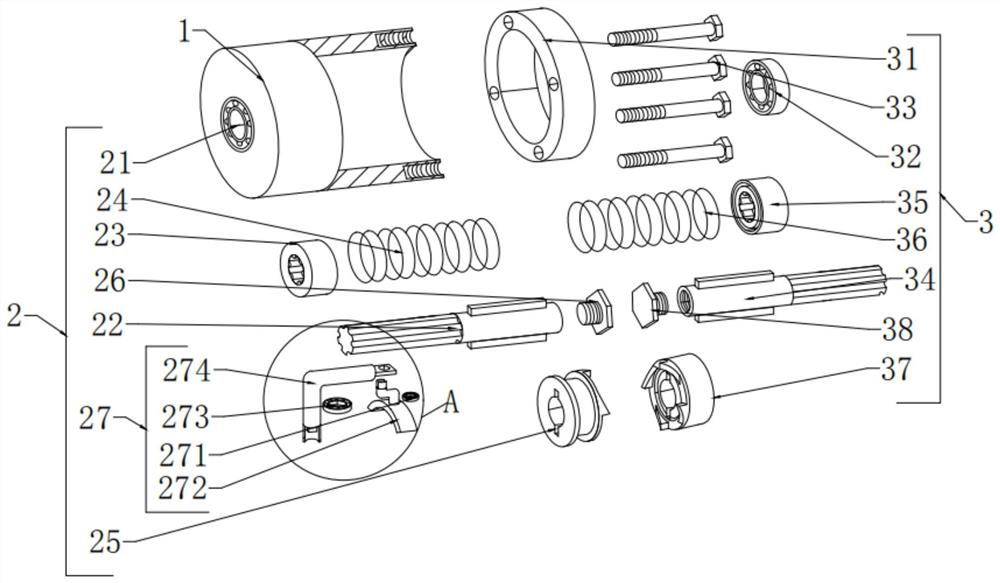

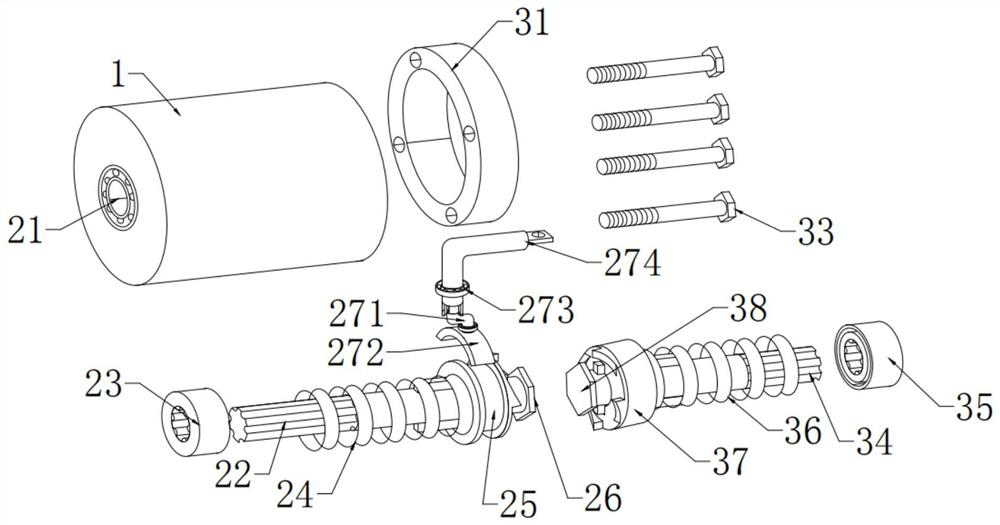

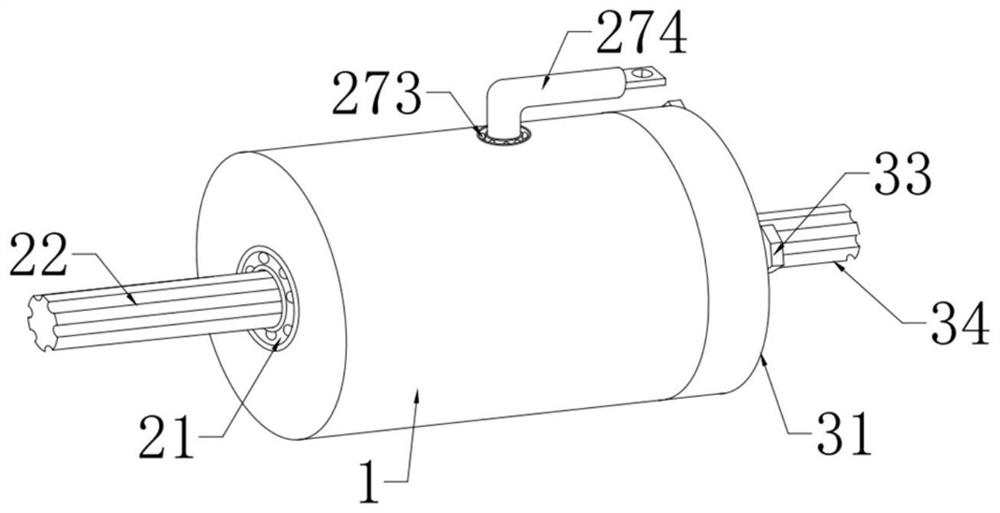

[0043] Embodiment: The cover body 31 in the transfer transmission structure 3 is fixed on the casing 1 by fixing bolts 33 for sealing, and the first shaft 22 in the control structure 2 can be connected with the driving device, and the second shaft can be connected at the same time 34 is connected with the transmission equipment; when in normal use, the first transmission wheel 25 and the second transmission wheel 37 are limited by the first limit bolt 26 and the second limit bolt 38, and the first spring 24 and the second spring 36 The force boxes are docked and snapped together, so that the first shaft rod 22 is rotated by the first limit bearing 21, and the second shaft rod 34 is rotated and transmitted by the second limit bearing 32; The driving rod 274 in the assembly 27 is connected with the equipment, and the driving rod 274 is rotated by the second mounting bearing 273 by applying force, and then the stressed rod on the driving member 272 is forced to drive the driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com