Rapid and accurate print shaping and drying device and using method thereof

A technology for shaping, drying and printing, applied to general parts of printing machinery, printing, printing machines, etc., can solve the problems of not providing a relatively complete equipment, long time, insufficient work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

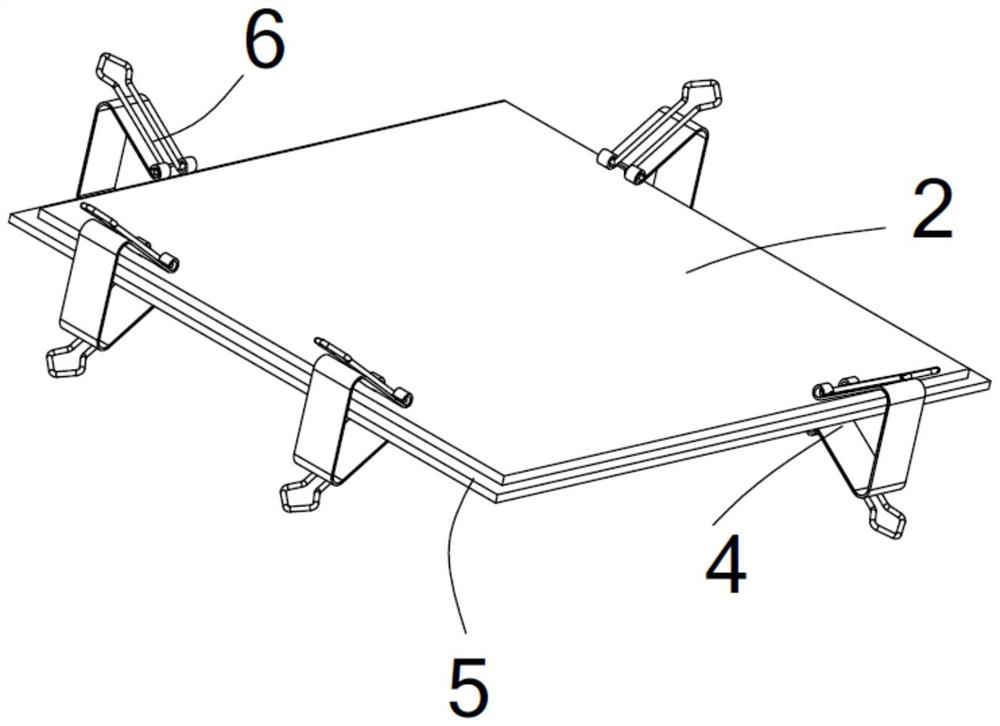

[0057] The present invention provides a drying device for rapid and precise printing of prints, which includes a placing table 10 and a hanger 20 .

[0058] The top of hanger 20 is connected on the placement platform 10, and one side of hanger 20 is connected with support frame 208, and support frame 208 is used for supporting on the ground; The plate 21 has a cross-shaped notch 23, and the pendant 22 has a fixed rod 24, a sliding ring 25, a first fixed plate 26, a first hinge plate 27, a second hinge plate 28, a third hinge plate 29, and a cross-shaped plate 31; One end of bar 24 is connected on the hanging plate 21 by fixing auxiliary bar 32, and cross plate 31 is also fixedly connected on the fixing auxiliary bar 32, and sliding ring 25 is sleeved on the fixing bar 24, and the outside of sliding ring 25 is fixed with four A group of first fixed plates 26, each group of fixed plates is hinged with a group of first hinged plates 28, the second hinged plate 28 and the third hi...

no. 2 example

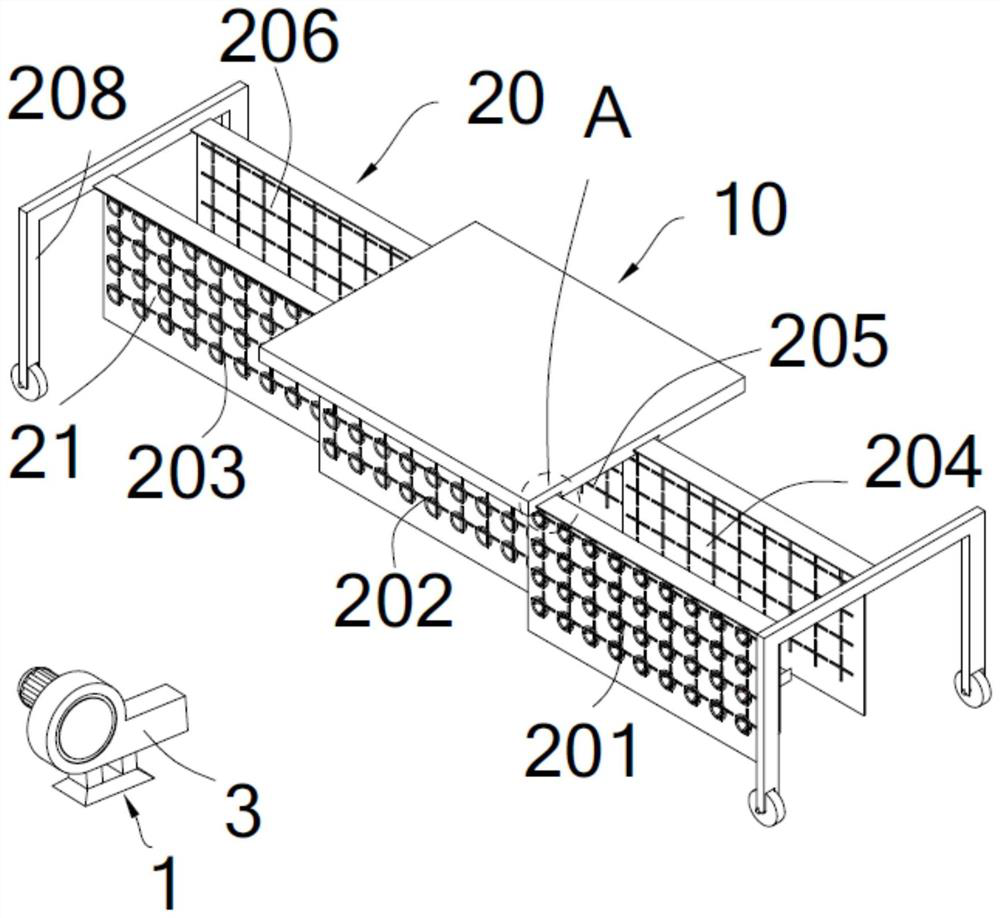

[0070] The placement table 10 of this embodiment has a chute structure, the hanger 20 has a sliding plate 41, the sliding plate 41 is arranged on the top of the hanging plate 21, and the sliding plate 41 is slidably arranged in the chute structure;

[0071] The chute structure has six groups of the first chute structure 11, the second chute structure 12, the third chute structure 13, the fourth chute structure 14, the fifth chute structure 15 and the Six sets of chute structures 16; the second set of chute structures 12 and the fourth set of chute structures 14 respectively fix the second set of hangers 202 and the fourth set of hangers 204, the first set of chute structures 11 and the fourth set of chute structures The chute structure 14 fixes the first group of hangers 201 and the fourth group of hangers 204 respectively, and one side of the first group of hangers 201 and the fourth group of hangers 204 is provided with a support frame 208, and the bottom of the support frame...

no. 3 example

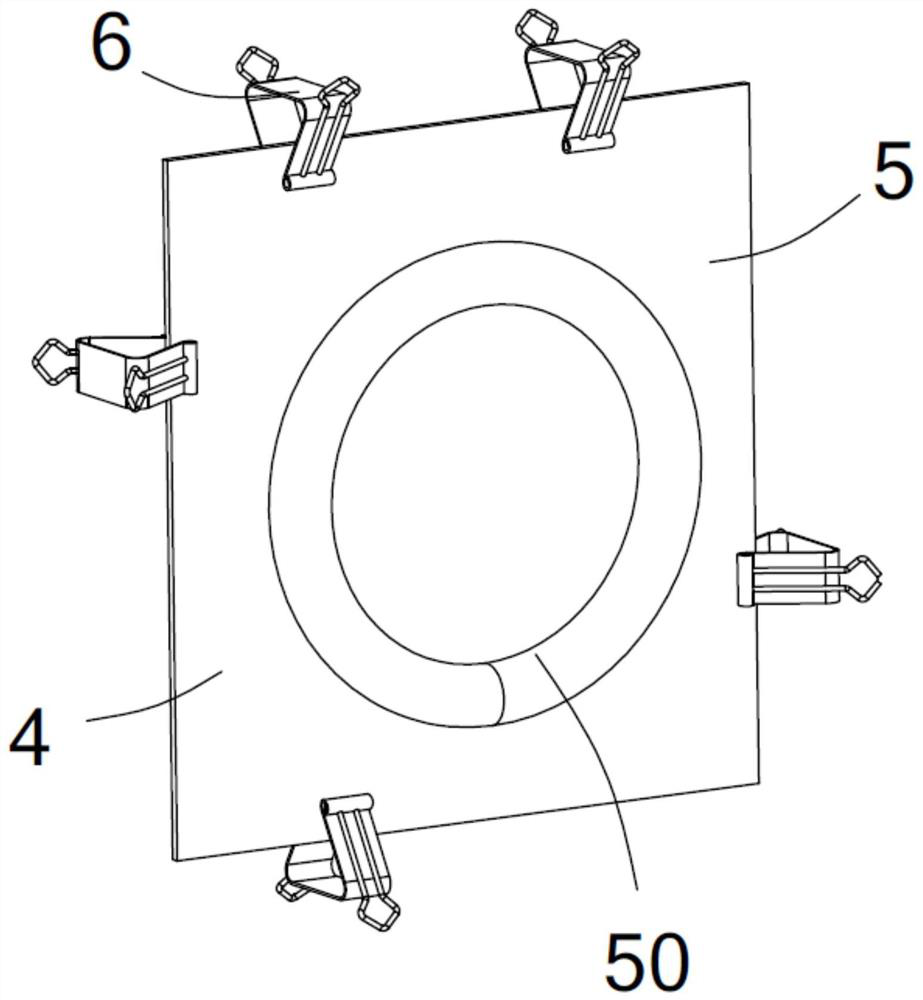

[0081] The top of the sliding plate 41 is suspended in the chute structure, and the sliding plate 41 has a locking piece, which is used to fix the sliding position of the sliding plate 41 .

[0082] Through the setting of the suspension structure, the sliding plate 41 and the hanger 20 can not only be moved, but also can be tilted to a certain extent. The purpose of this is to facilitate the hanger 20 when the ring member 50 needs to be shaken off. The hanging rack 20 is tilted and flipped, so that the ring parts 50 can be dropped quickly and collectively, and then the fast collection and storage can be completed.

[0083] Through the setting of the suspension structure, the sliding plate and the hanger can not only be moved, but also can be tilted to a certain extent. The hanger is tilted and flipped, so that the ring parts can be quickly concentrated and dropped, and then the rapid collection and storage can be completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com