Blowing and suction switching structure for blowing and suction fan and blowing and suction fan

A technology of blowing and sucking fans and switching structures, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., and can solve problems such as weak suction or suction performance, high cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

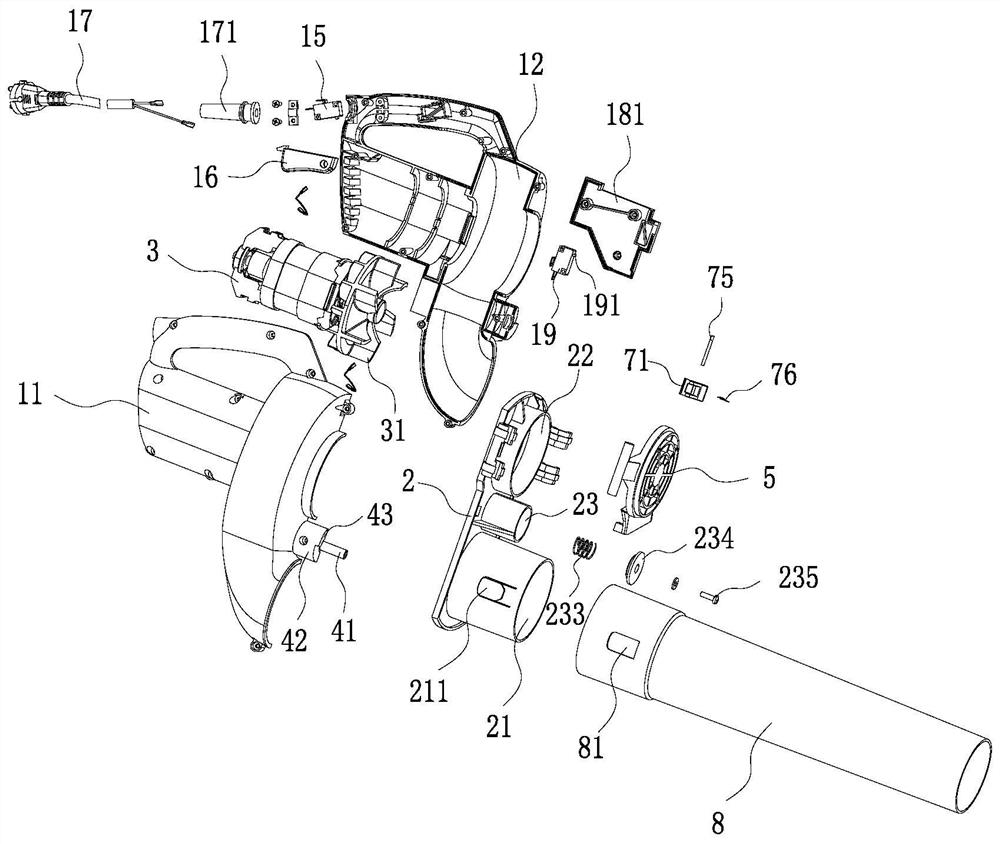

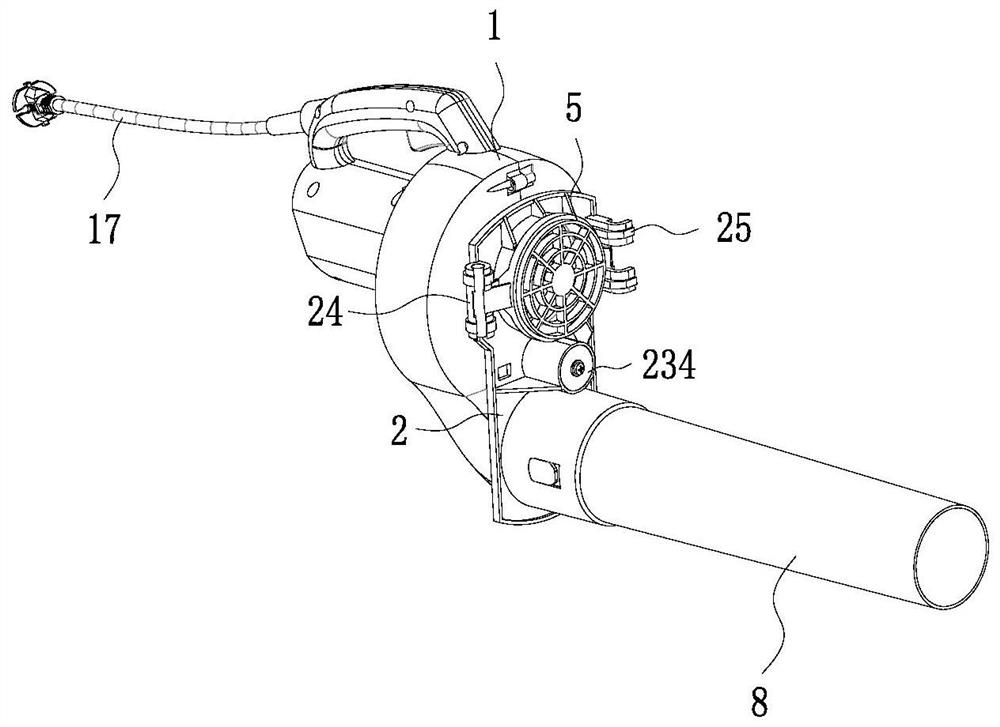

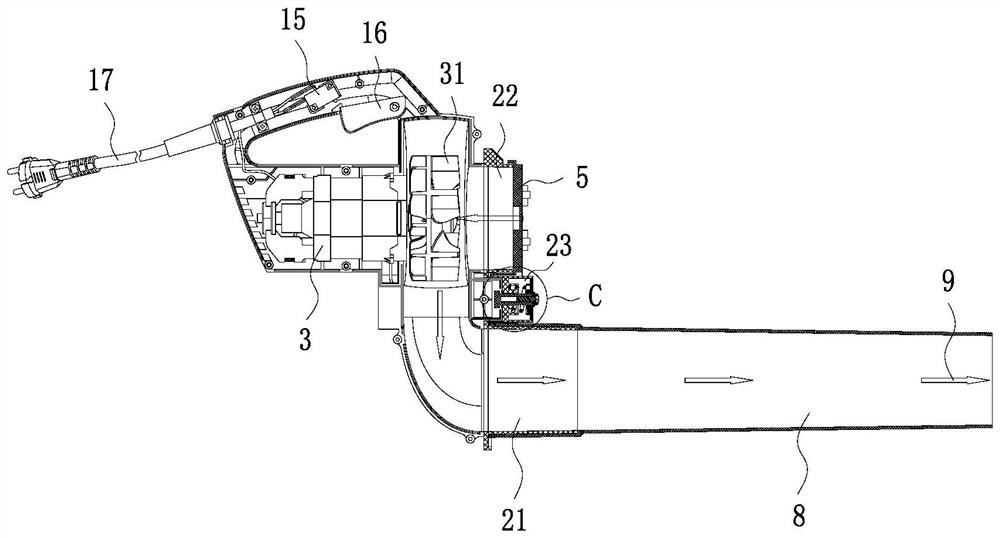

[0045] like Figure 1 to Figure 19 As shown, this embodiment shows a blowing-suction conversion structure for a blower-suction fan, including a casing 1 and a bracket 2, the surface of the casing 1 is provided with an air inlet 13 and an air outlet 14, and the air inlet 13 Between the air outlet 14 and the stud 41 for mounting the bracket 2, the bracket 2 is provided with a first air outlet 21 and a second air outlet 22, the bracket 2 is rotatably connected with the stud 41, and the first air outlet An air duct 8 is installed on the 21, and an air inlet cover 5 or a dust collection bag 6 is installed on the second air outlet 22. When the first air outlet 21 is connected with the air inlet 13, the blower is in a suction mode, When the first air outlet 21 is docked with the air outlet 14, the blowing and suction fan is in the blowing mode, and the bracket 2 rotates around the stud 41 to switch between the blowing and suction modes.

[0046] In this embodiment, the air inlet 13 ...

Embodiment 2

[0056] like Figures 1 to 9 As shown, this embodiment shows a blower, the blower is provided with the conversion structure of the blower as described in Embodiment 1 or other same embodiments, the casing 1 in this embodiment includes a left The casing 111 and the right casing 121, the left casing 111 and the right casing 121 are spliced by screws 235, the power cord 17 is installed on the right casing 121, and the connection between the power cord 17 and the right casing 121 A power supply sheath 171 is sheathed at the center, and the casing 1 includes a handle on which a power switch 15 and a power supply pressing plate 16 are arranged. The power cord 17 is connected to the power switch 15. By pressing the power supply Pressing plate 16 just can make power switch 15 open.

[0057] The switching process of the blowing mode of the blowing fan described in this embodiment is as follows:

[0058] Suction mode: the first air port 21 is docked with the air inlet 13, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com