A method and device for monitoring a multi-modal process of strip hot rolling

A technology of process monitoring and hot continuous rolling, applied in the direction of reasoning method, calculation model, character and pattern recognition, etc., can solve the problem of not considering the limitation of state residence time distribution, and achieve the effect of good monitoring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

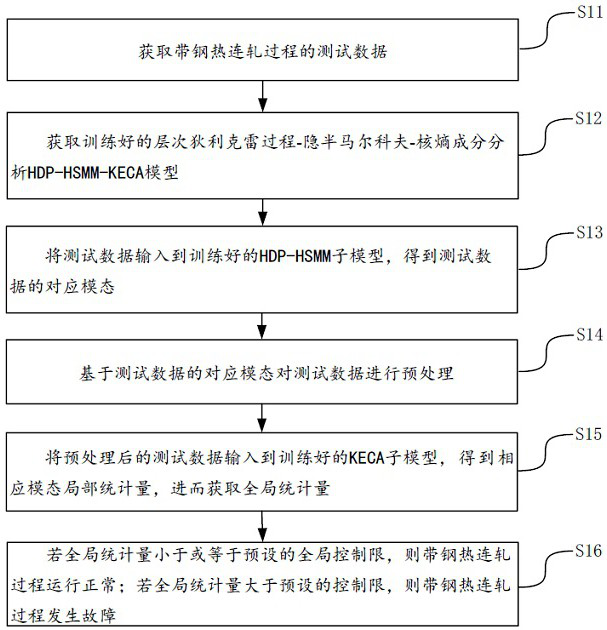

[0099] Such as figure 1 As shown, the embodiment of the present invention provides a multi-modal process monitoring method for strip hot rolling, which can be implemented by electronic equipment. Such as figure 1 The flow chart of the multi-modal process monitoring method for hot continuous rolling of strip steel is shown, and the processing flow of the method may include the following steps:

[0100] S11. Obtain the test data of the strip hot rolling process.

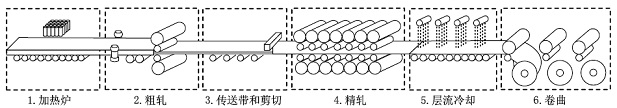

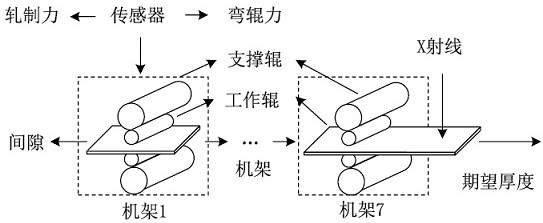

[0101] In a feasible implementation mode, the strip hot rolling process is a steel production process with complex mechanism, large scale, high efficiency and multiple processes, and is a typical complex process industry. Such as figure 2 As shown, the production line is mainly composed of h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap