New energy automobile battery installation clamp

A new energy vehicle, installation fixture technology, applied in secondary battery manufacturing, battery pack components, circuits, etc., can solve problems such as hidden safety hazards, low efficiency, and inability to be neatly classified, and achieve the effect of improving installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

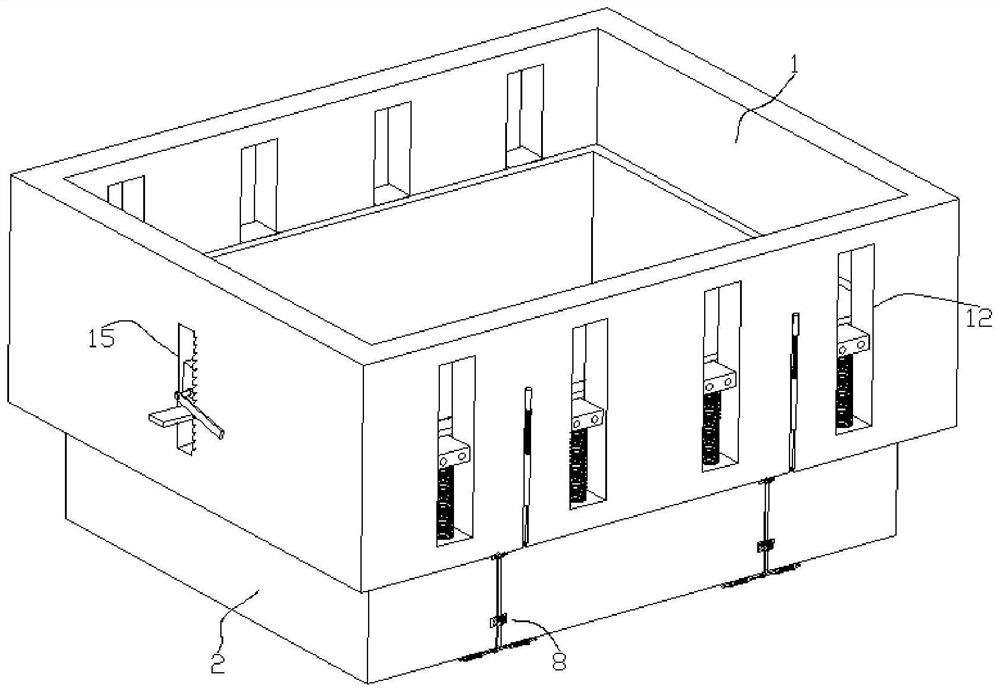

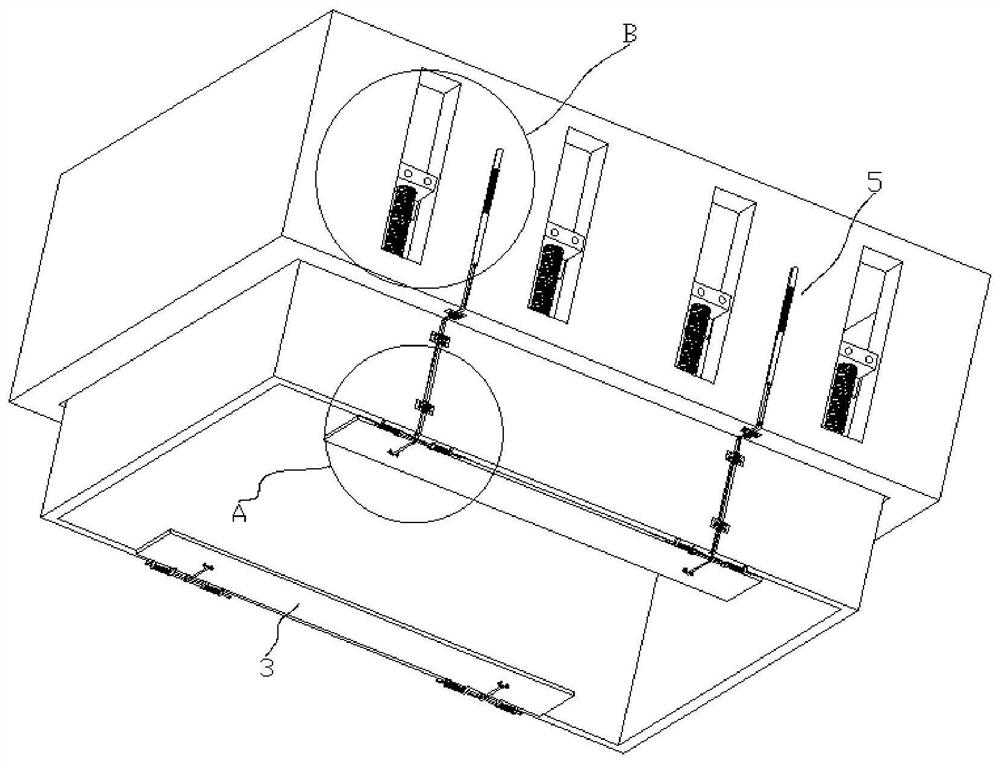

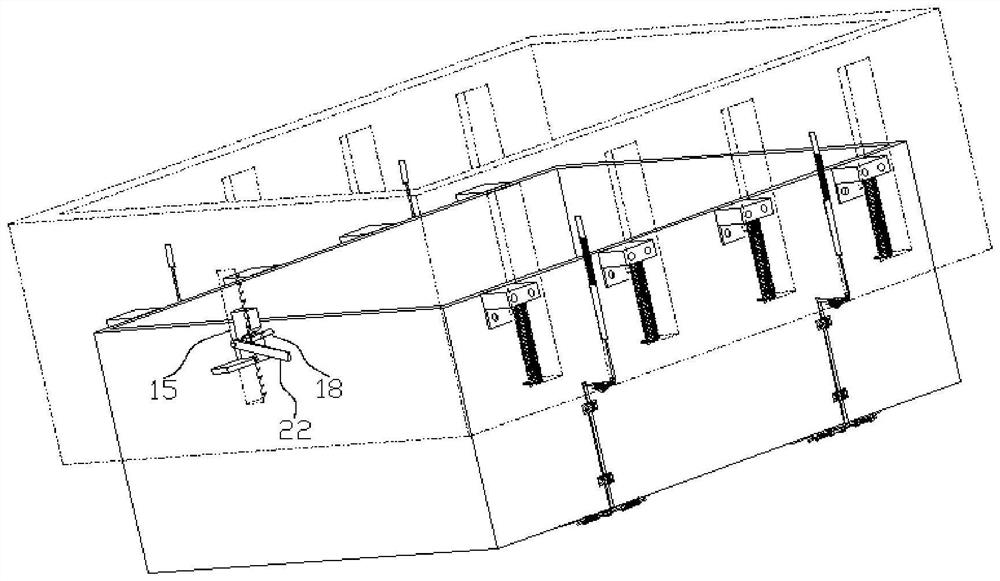

[0025] Such as Figure 1~3 As shown, the new energy vehicle battery installation jig of the present invention includes an outer shell 1 and an inner loading box 2 arranged on the outer shell 1. Both the outer shell 1 and the inner loading box 2 are rectangular, and the outer size of the inner loading box 2 is slightly smaller than that of the outer shell 1. According to the size of the inner side wall, the inner loading box 2 can slide vertically relative to the outer shell body through direct sliding fit. Both sides of the bottom of the inner loading box 2 are provided with a carrying plate 3, the carrying plate 3 is also rectangular, the carrying plate 3 is arranged along the length direction of the inner loading box 2, and one side edge of the carrying plate 3 is in contact with the inner loading box 2. The loading box 2 is pivotally connected, so it can rotate along the long side, and an elastic support device 4 is arranged between the loading plate 3 and the inner loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com