Intelligent high-efficiency moxa cutting device for moxa stick processing and production

A high-efficiency, moxa stick technology, applied in metal processing and other directions, can solve the problems of easy incision inclination, increased energy consumption, lack of moxa stick deviation correction mechanism, etc., to achieve the effect of saving energy consumption and ensuring the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

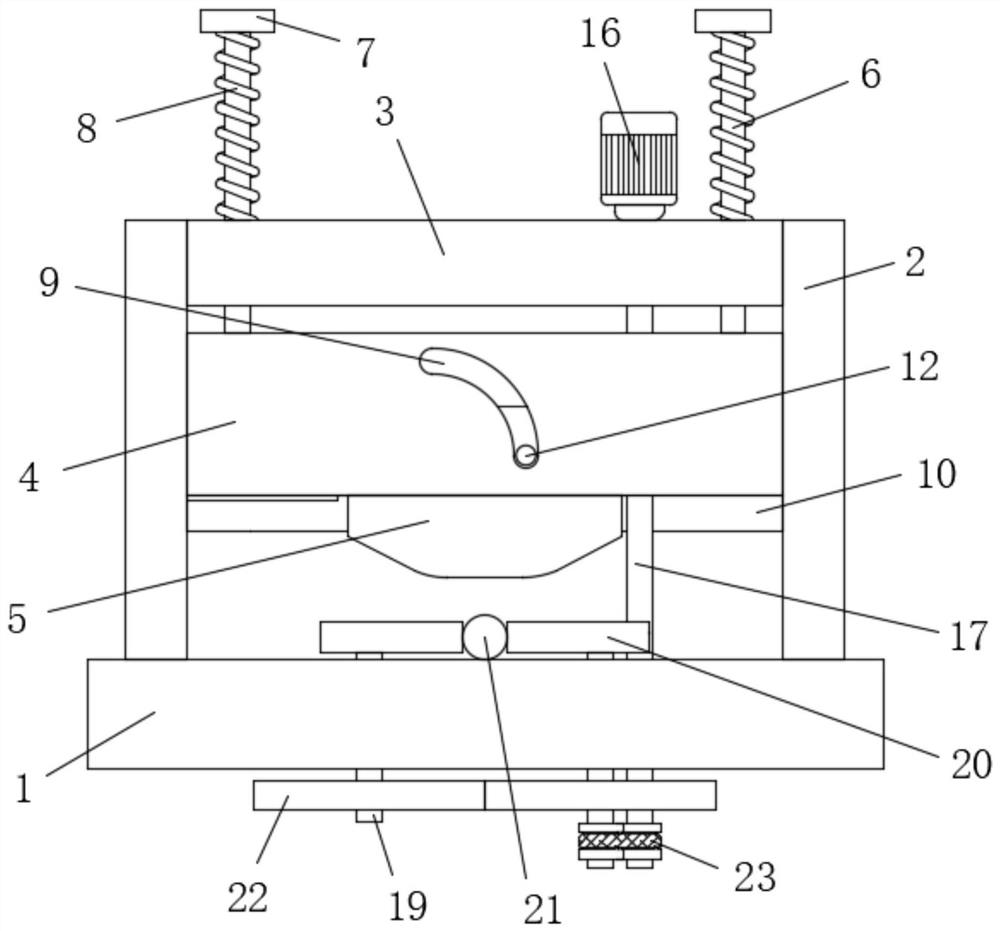

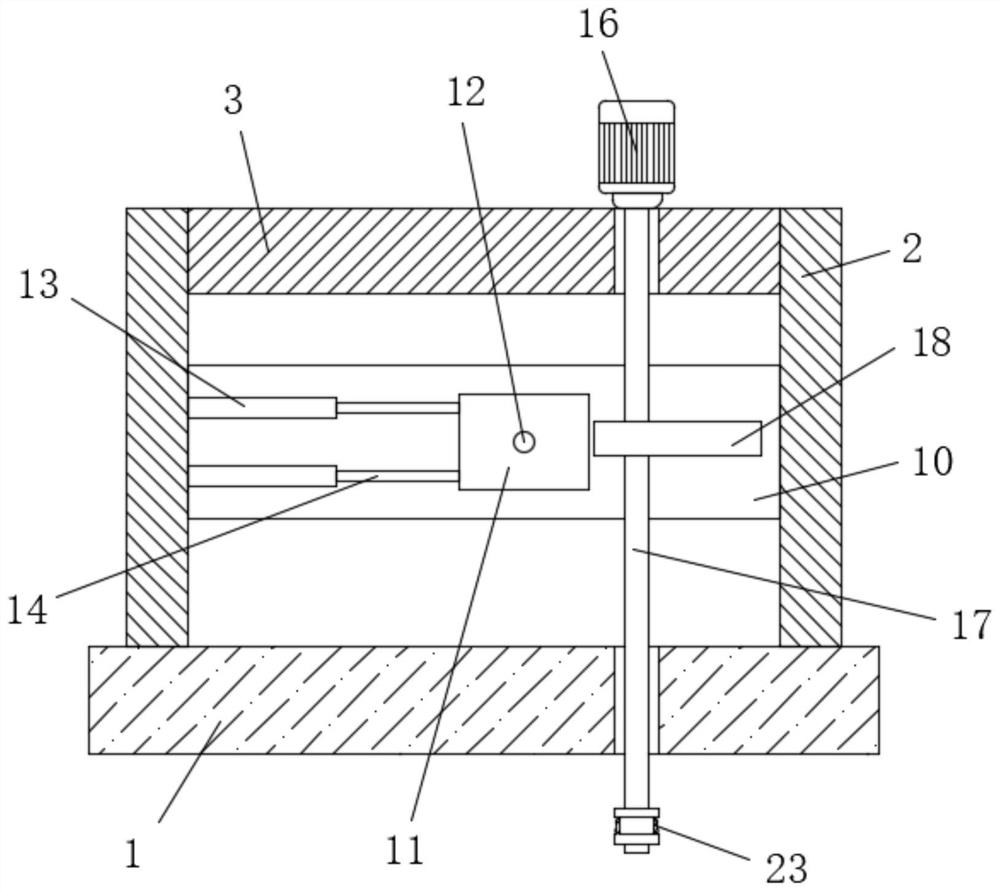

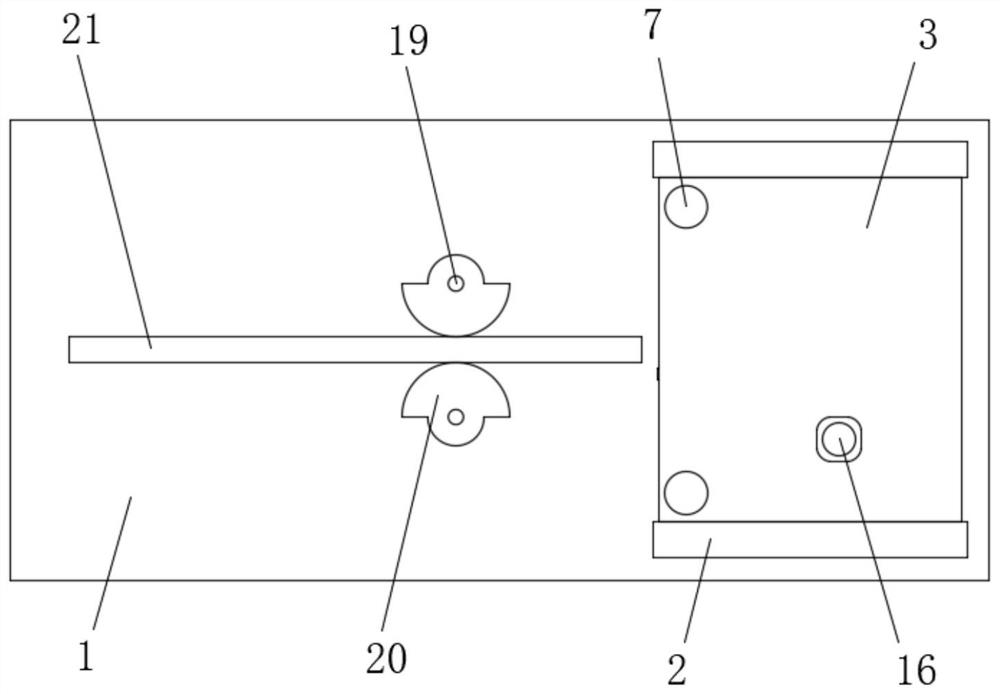

[0027] refer to Figure 1-6 , an intelligent and high-efficiency moxa cutting device for moxa stick processing and production, comprising a cutting table 1, two vertical boards 2 are symmetrically fixedly connected to one side of the top of the cutting table 1, and the top of one side of the two vertical boards 2 is close to each other The same top plate 3 is fixedly connected, the side of the two vertical plates 2 close to each other is slidably connected to the same mobile plate 4, the bottom of the mobile plate 4 is fixedly connected to the cutter 5, and the sides of the two vertical plates 2 close to each other are fixed The same fixed plate 10 is connected, and the side of the fixed plate 10 close to the moving plate 4 is provided with a transmission assembly that moves with the fixed plate 10. The top of the top plate 3 is fixedly connected with a motor 16, and the output shaft of the motor 16 is fixedly connected with a second A rotating rod 17, one end of the first rot...

Embodiment 2

[0029] Further improvement on the basis of Embodiment 1: the top of the moving plate 4 is symmetrically fixedly connected with two moving rods 6, and the top ends of the two moving rods 6 all extend to the top of the top plate 3 and are fixedly connected to the limit block 7. One side of the moving rod 6 is sleeved with a first spring 8, and the bottom ends of the two first springs 8 are fixedly connected with the top of the top plate 3 respectively, and the top ends of the two first springs 8 are respectively connected with the corresponding limit block 7. The bottom of the fixed plate is fixedly connected, and the moving rod 6 can be reset by the first spring 8, thereby realizing the reset of the moving plate 4. The transmission assembly includes a moving block 11 that is slidably connected to one side of the fixed plate 10, and the moving block 11 moves close to One side of the plate 4 is fixedly connected with a strut 12, and the side of the moving plate 4 near the moving b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap