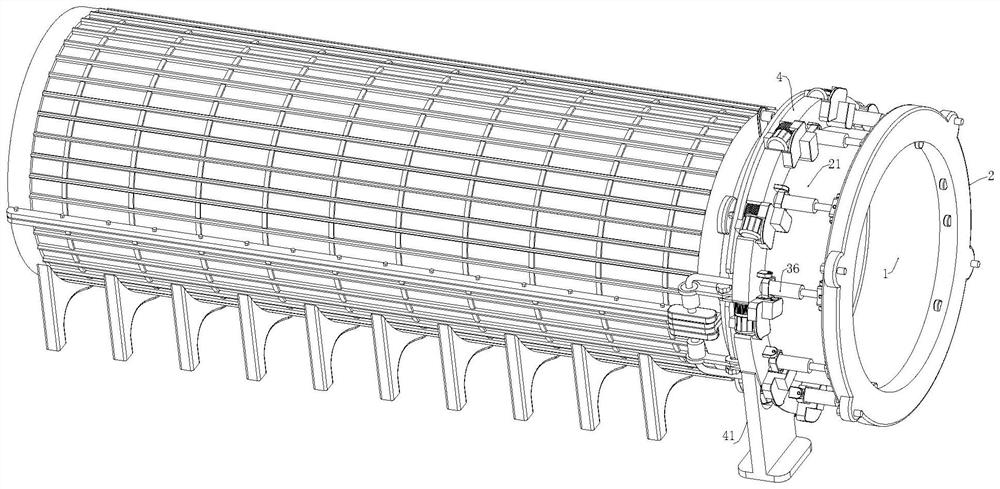

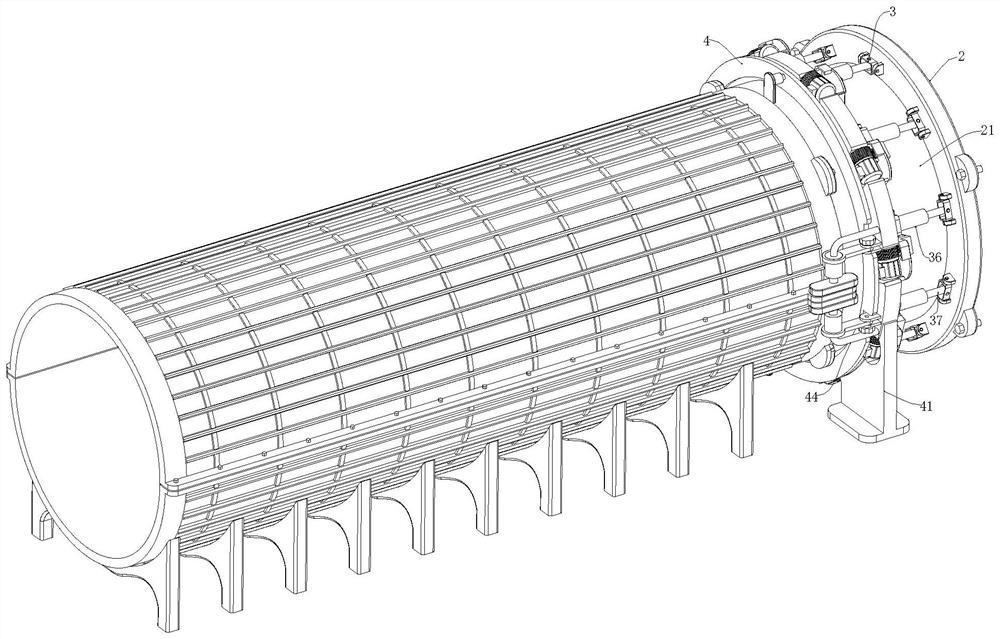

Device for measuring attitude of shield in steel sleeve

A technology of shield attitude and measuring device, which is used in measuring device, surveying and navigation, instruments, etc., can solve the problems of large vibration force, steel sleeve offset, affecting the accurate detection of shield machine, etc. Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

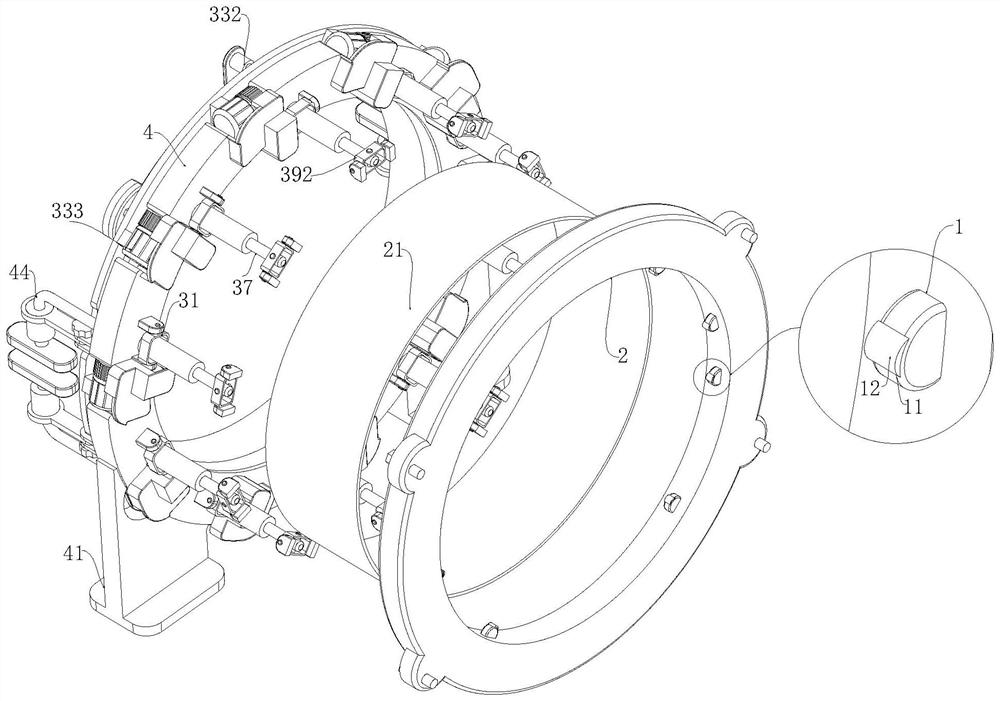

[0074]The connector 5 includes a plurality of first positioning ears 51 installed on the side of the fixing plate 4 close to the steel sleeve, and the first positioning ears 51 are threadedly connected with the second positioning ears 52 through the provided sealing bolts. The positioning ears 52 are fixedly installed on the steel sleeve;

[0075] At the same time, the side of the steel sleeve close to the fixed plate 4 is provided with a sealing groove, the sealing groove is provided with a sealing ring, and the position of the fixed plate 4 corresponding to the sealing groove is provided with a protrusion, so as to ensure the gap between the fixed plate 4 and the steel sleeve. The tightness of the connection.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap