Automatic bagging and packaging equipment for paper cup production

A technology for packaging equipment and paper cups, which is applied in the field of automatic bagging and packaging equipment for paper cup production, can solve the problems of cumbersome operation process, affecting the processing efficiency of disposable paper cups, and easy loosening of paper cups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

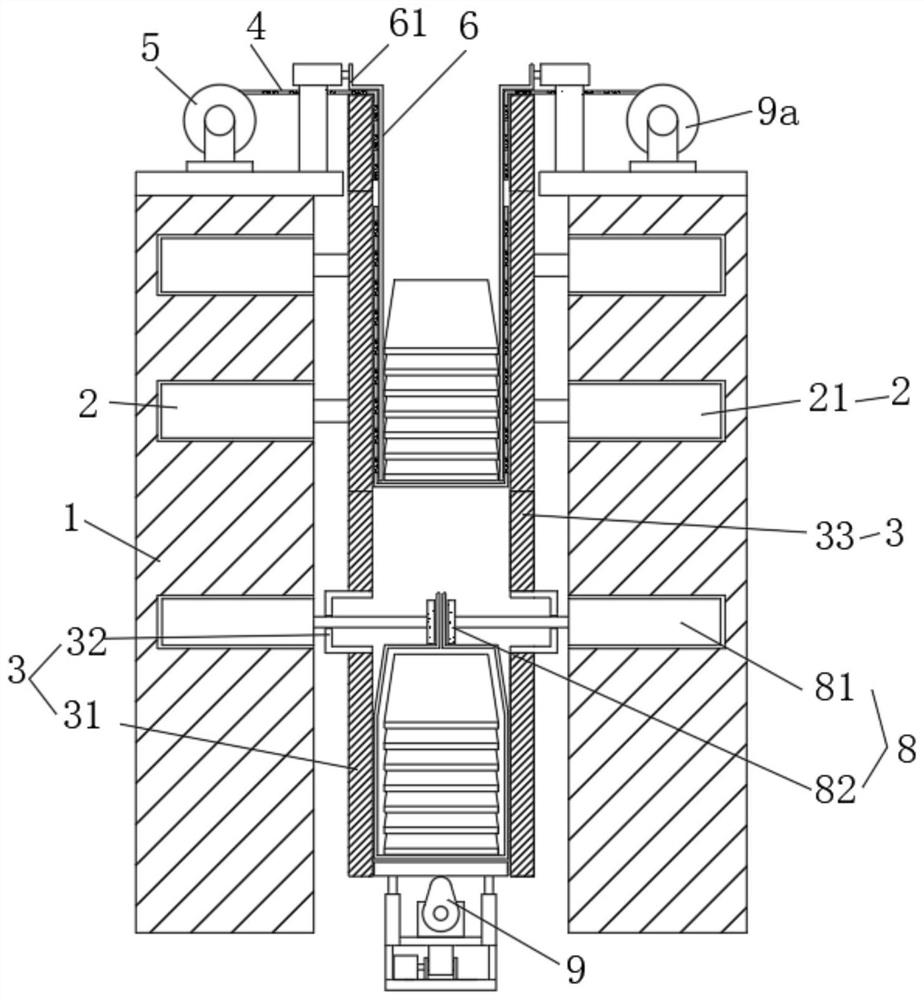

[0033] like Figure 1-Figure 3 As shown, an automatic bagging and packaging equipment for paper cup production includes a processing cylinder 3, and the processing cylinder 3 includes an upper cylinder 33, an edge sealing box 32 and a lower cylinder 31 arranged sequentially from top to bottom;

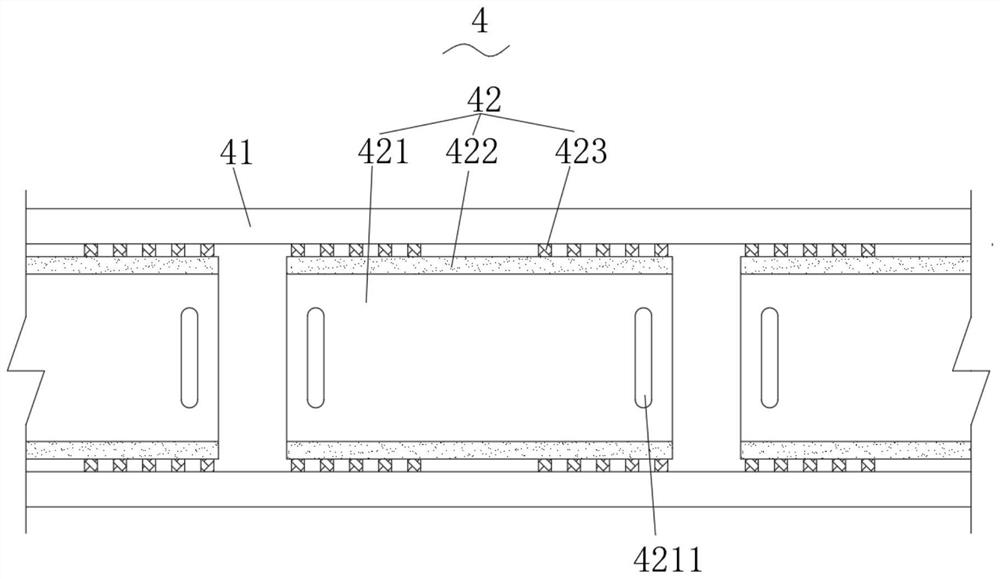

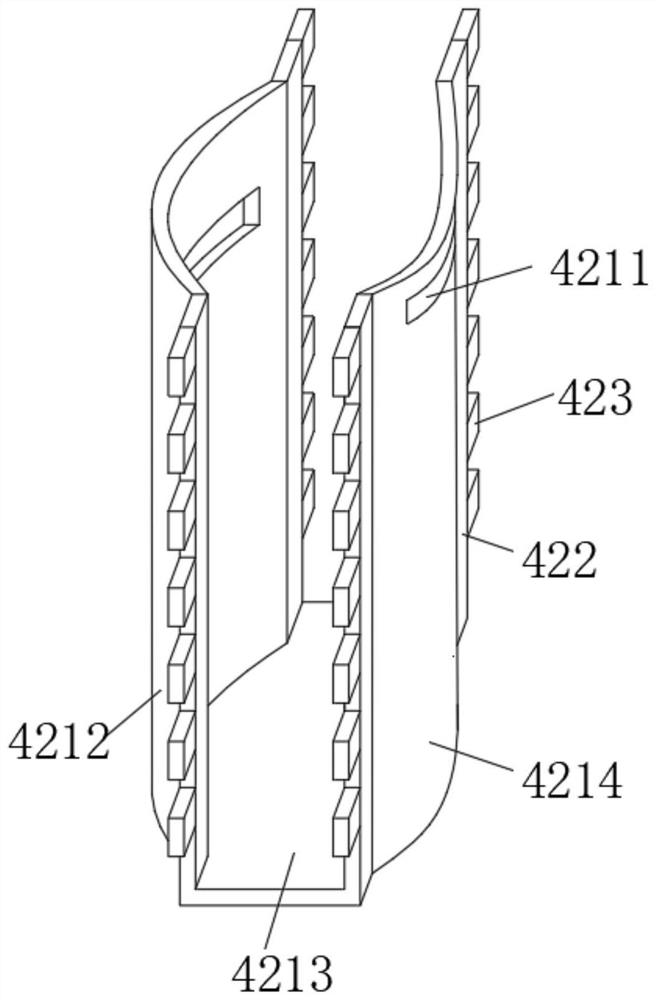

[0034] The first heat-sealing assembly 2 is installed on the outer side of the upper cylinder 33, the inner splint 6 is arranged at intervals on the inner side of the upper cylinder 33, and the area between the upper cylinder 33 and the inner splint 6 is a film-coated belt In the penetration area, the coating tape enters from one side of the coating tape penetration area and passes through the other side; the inner splint 6 is used to press the coating tape 4 to the inner wall of the upper cylinder 33; the upper cylinder 33 It is the stacking part of the paper cup and the side heat sealing part. The film-coated tape can circulate through the upper cylinder, so that the main bodies of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com