Method and system for automatically, continuously and uniformly calibrating curvature of bending sensor

A technology of sensors and ranging sensors, which is applied in the field of automatic, uniform curvature calibration and continuous bending sensors, can solve the problems that the service life of the bending sensor cannot be guaranteed, it is not universal, and it is difficult to do it, so as to expand the range of curvature calibration, Improved accuracy and controllable bending speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

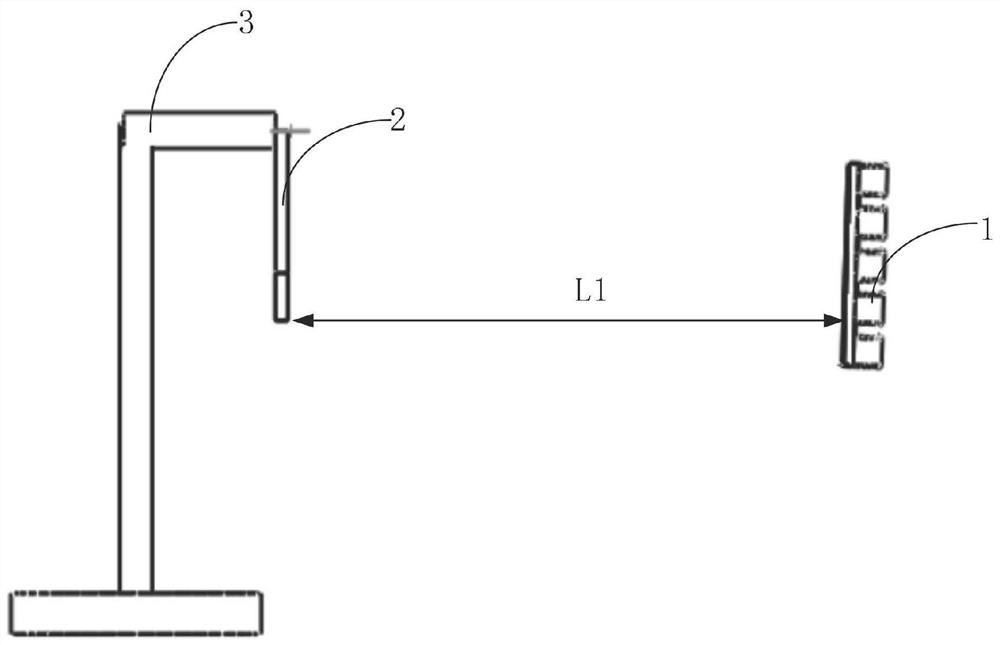

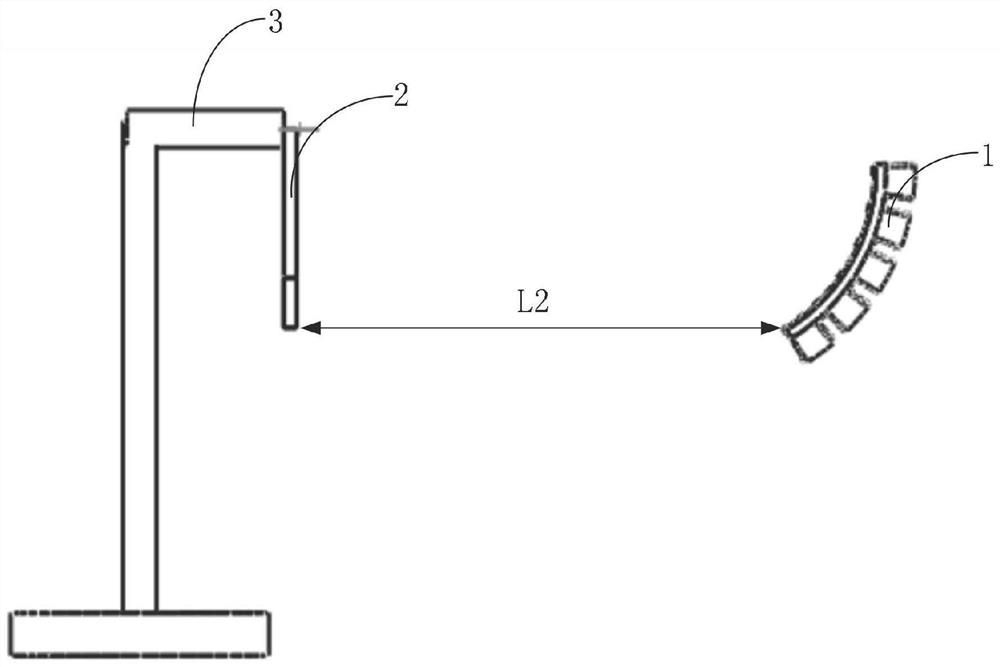

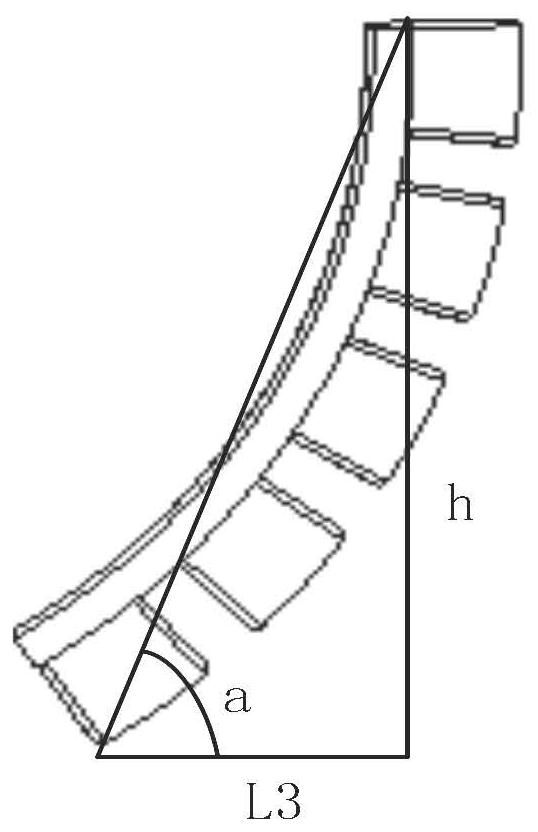

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following is a preferred one of the multiple possible embodiments of the present invention, intended to provide a basic understanding of the present invention, but not intended to identify key or decisive elements of the present invention or limit the scope of protection.

[0038] In the description of the present invention, it should be noted that unless otherwise specified and limited, the terms "installation" and "connection" should be understood in a broad sense, for example, it can be a fixed connection, a detachable connection, or an integral Ground connection; it can be a mechanical connection or an electrical connection; it can be a direct connection or an indirect connection through an intermediary, and it can be the internal communication of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com