Simple Liquid-column type measuring device for calibrating vacuum

A measuring device and liquid column technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of transmitter measurement distortion, measurement range cannot be verified, and affect operation judgment, so as to reduce errors, measure accurately, The effect of meeting the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

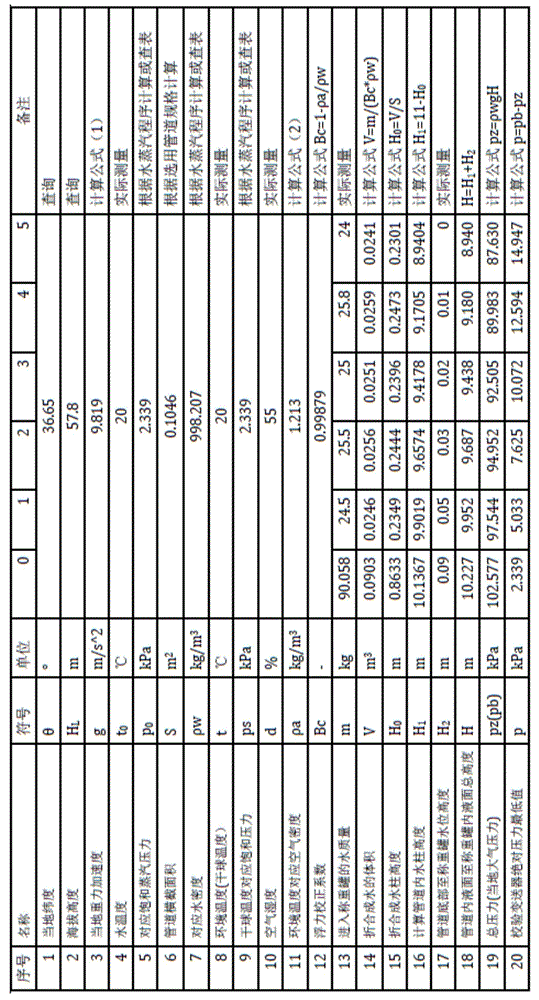

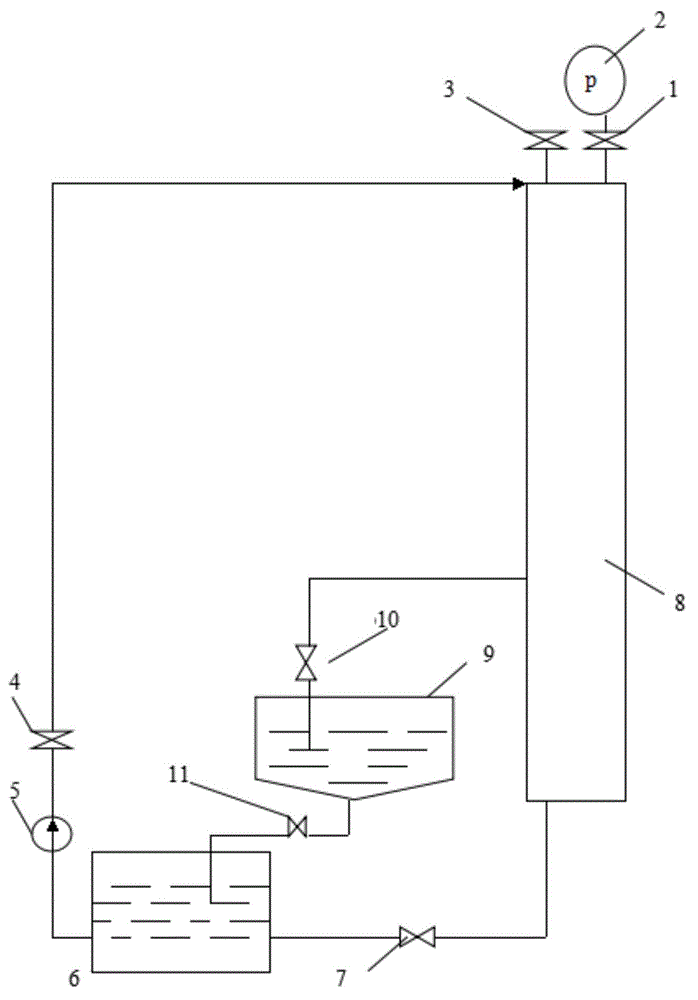

[0023] Embodiment 1: long 11 meter pipeline 8 adopts international standard round steel, pipeline specification 377×6, pipe cross-sectional area S=π*D 2 / 4=3.141593*0.365 2 / 4=0.104635m 2 , the volume after being filled with water V=L*S=11*0.104635=1.150981m 3 .

[0024] The water pump 5 is a miniature water pump with a flow rate of 100L / min and a head of 15m. The maximum weighing capacity of weighing tank 9 is 1.5 tons, and the minimum resolution is gram. Measuring barrel 6 bottom area 1.5m 2 , 1 meter high, maximum measuring volume 1.5m 3 . The valve adopts a needle valve with good sealing performance. Suppose there is an absolute pressure transmitter with a range of 0-15kPa, and its most commonly used range is 5.0kPa.

[0025] Use pure water at 20°C as the calibration medium.

[0026] Step (1): Install the transmitter to be calibrated 2, open the connection valve 1, open the air isolation valve 3, the pump outlet valve 4, the drain valve A7 at the bottom of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com