Large barrel self-locking lifting device and lifting method

A lifting device and large-scale cylinder technology, applied in the direction of safety devices, transportation and packaging, load hanging components, etc., can solve the problems of high operation safety risk, long operation time, high safety risk, etc., to avoid high hook operation, Prevent slipping and achieve the effect of lifting and self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

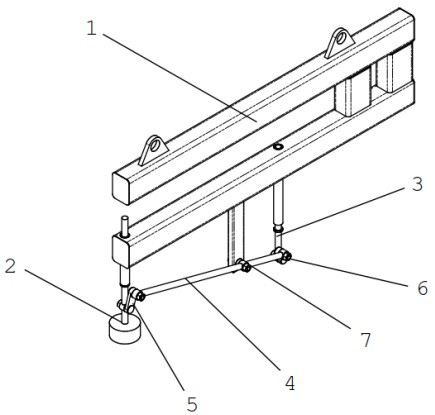

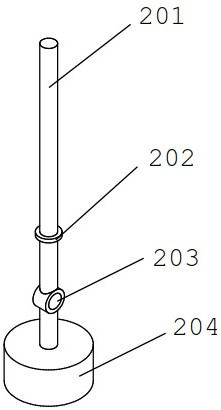

[0028] see Figure 1-Figure 8 , This embodiment provides a self-locking lifting device for a large cylinder, including a spreader body 1 , an anti-loosening rod 2 , a pressure rod 3 , a lever 4 , a front connecting assembly 5 , a rear connecting assembly 6 , and a middle connecting assembly 7 . In the non-working state, under the action of gravity and leverage, the anti-off bar 2 with the counterweight 204 is at the lowest position, and the pressure bar 3 is at the highest position and protrudes from the lower arm 102 of the spreader body 1 . When the cylinder body is hoisted, the pressure rod 3 is pressed down, and the anti-loosening rod 2 is raised by the action of the lever 4 to realize the lifting self-locking function. The status of the cylinder lifting operation.

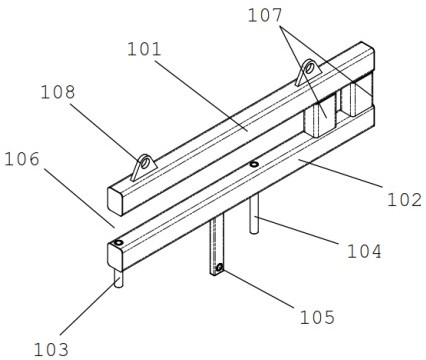

[0029] Such as figure 2 As shown, the upper arm 101 and the lower arm 102 on the spreader body 1 are connected by a single-sided connecting arm 107 to form a C-shaped opening 106, which can be lifted throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap