Pressure flow meter and fluid control device

A fluid control device and fluid control valve technology, applied in flow control, flow control using electrical devices, measuring devices, etc., can solve problems such as changes in flow characteristics of fluid resistance elements, inability to fully press sealing parts, and deformation of fluid resistance elements, etc. To achieve the effect of improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

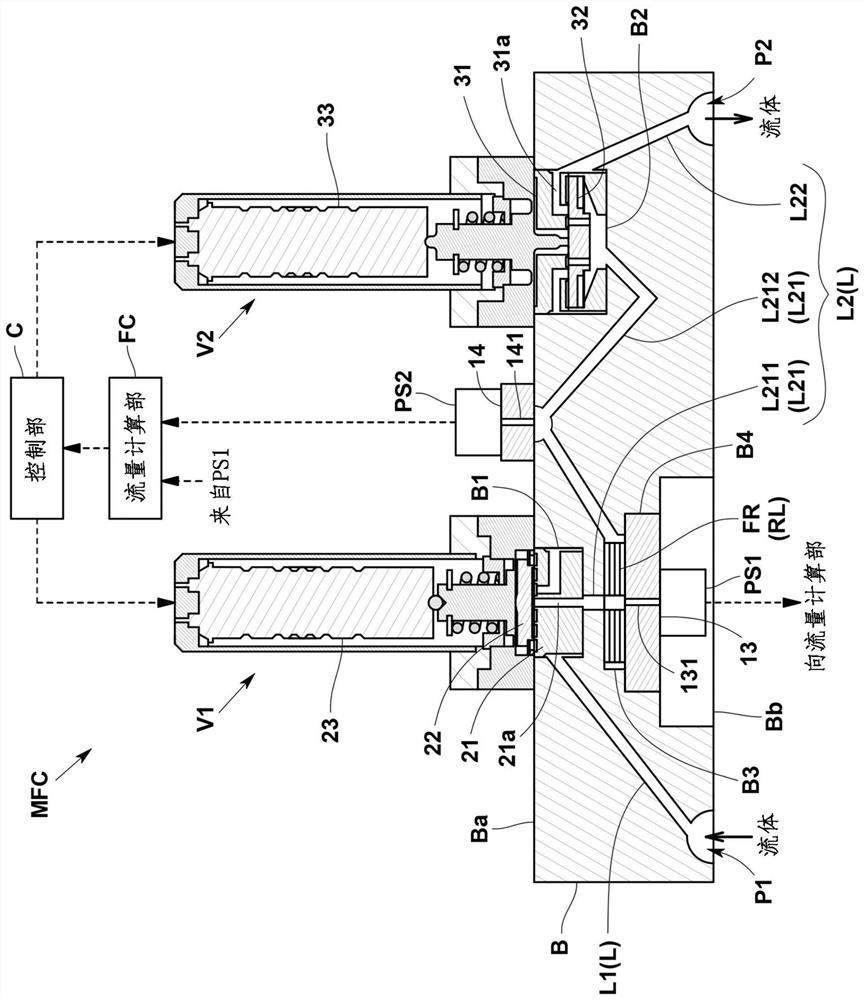

[0044] Hereinafter, a fluid control device (mass flow controller) according to one embodiment of the present invention will be described with reference to the drawings.

[0045]

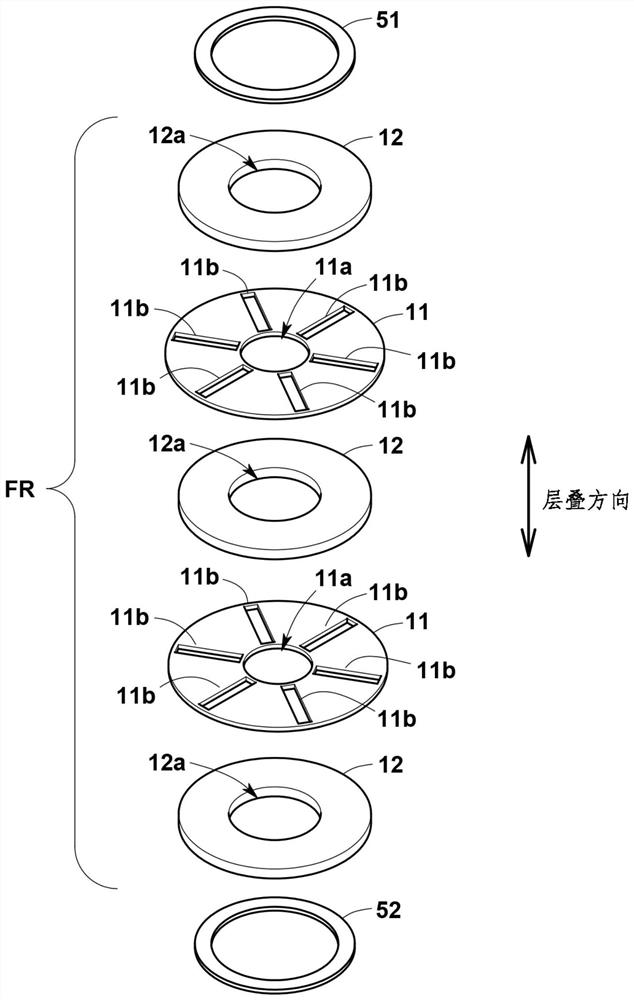

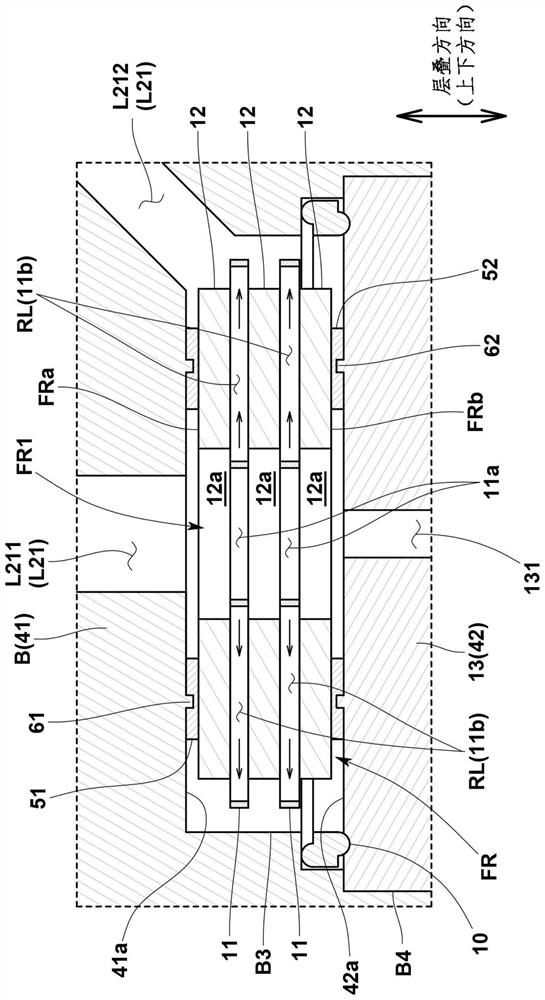

[0046] Such as figure 1 As shown, the fluid control device MFC of this embodiment is a pressure type. Specifically, the fluid control device MFC includes: a block B, in which a flow channel L for fluid flow is formed; a fluid resistance element FR, provided on the flow channel L of the block B; an upstream side pressure sensor PS1, provided at Block B is used to detect the upstream side pressure of the fluid resistance element FR; the downstream side pressure sensor PS2 is installed on the block B to detect the downstream side pressure of the fluid resistance element FR; the first fluid control valve V1 is located in the flow channel of the block B L is provided on the upstream side of the fluid resistance element FR; and a control part C performs feedback control on the first fluid control valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com