Frequency conversion refrigeration compressor motor performance test system

A technology of refrigeration compressors and testing systems, applied in the direction of motor generator testing, measuring electricity, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

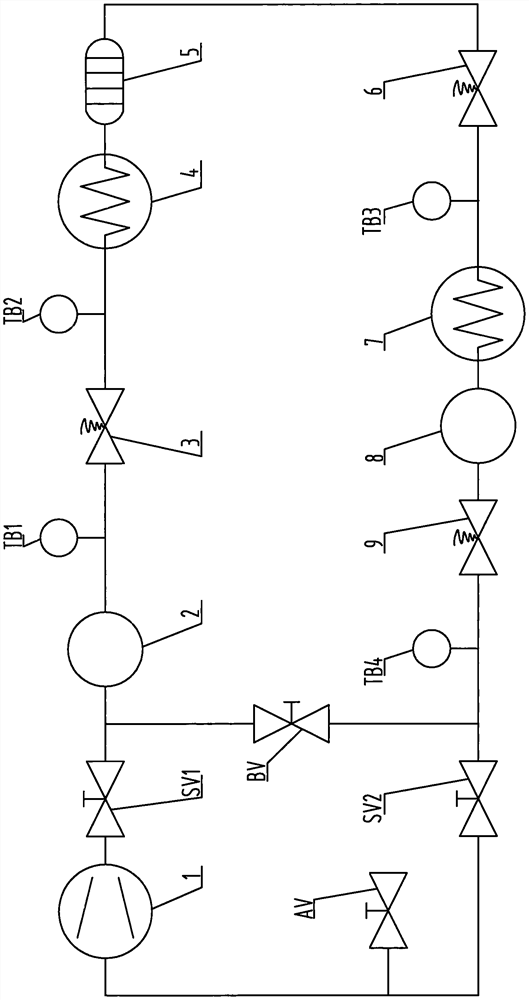

[0011] See figure 1 As shown, a closed frequency conversion refrigeration compressor motor performance test system includes a refrigeration compressor 1 connected to a circulation loop, an exhaust shut-off valve SV1, an exhaust air storage tank 2, a compressor performance test flow regulating valve 3, and a condenser 4 , dry filter 5, refrigerant liquid flow regulating valve 6, evaporator 7, gas-liquid separator 8, compressor suction flow control regulating valve 9 and return air cut-off valve SV2, wherein, refrigeration compressor 1 has a high pressure exhaust The outlet port and the low-pressure return air inlet port are connected with the process valve AV between the return air shut-off valve SV2 and the low-pressure return air inlet port. The process valve is used for air charging, pressure test, leak detection, vacuuming, refrigerant filling and displacement refrigeration. Working fluid; connect the compressor performance test table TB1 on the pipeline between the exhaust...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap