Guide vane type desilting funnel

A guide-blade and funnel technology, applied in marine engineering, construction, artificial waterways, etc., can solve the problems of low sediment discharge rate and sediment deposition in bottom holes, so as to solve the problem of reducing the sediment discharge rate and improving the sediment discharge rate. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

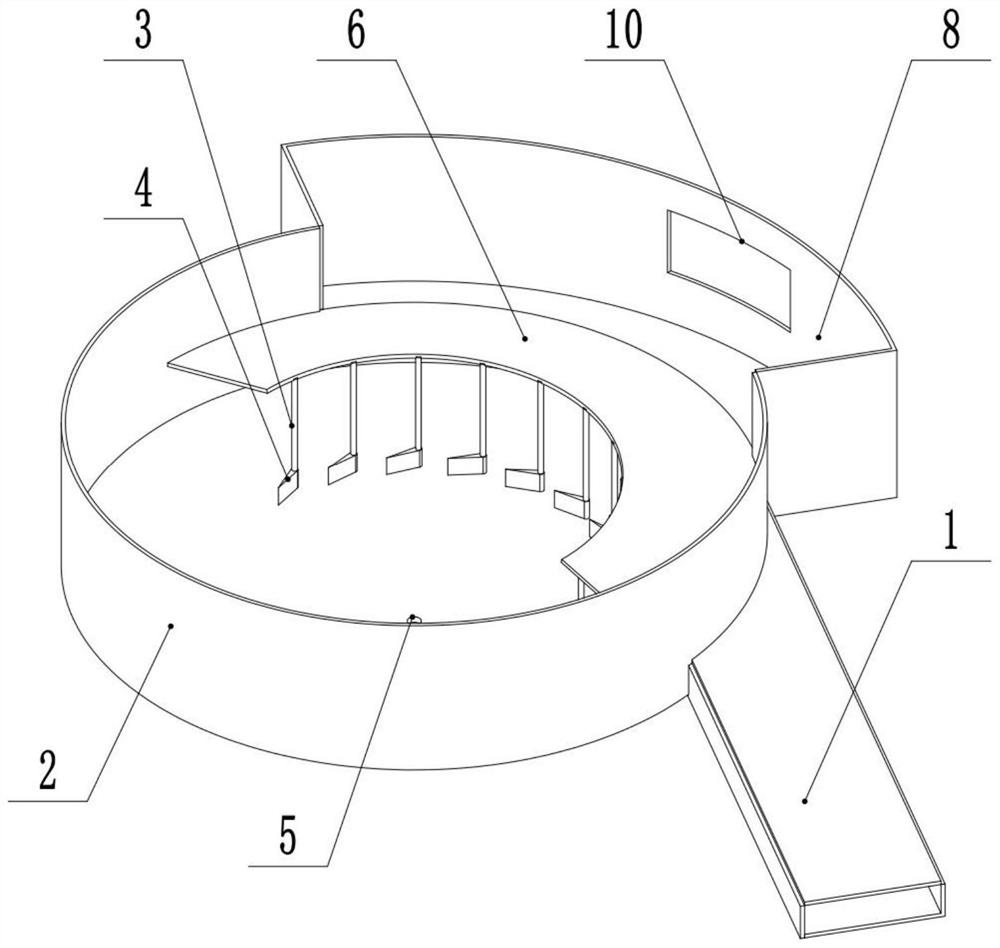

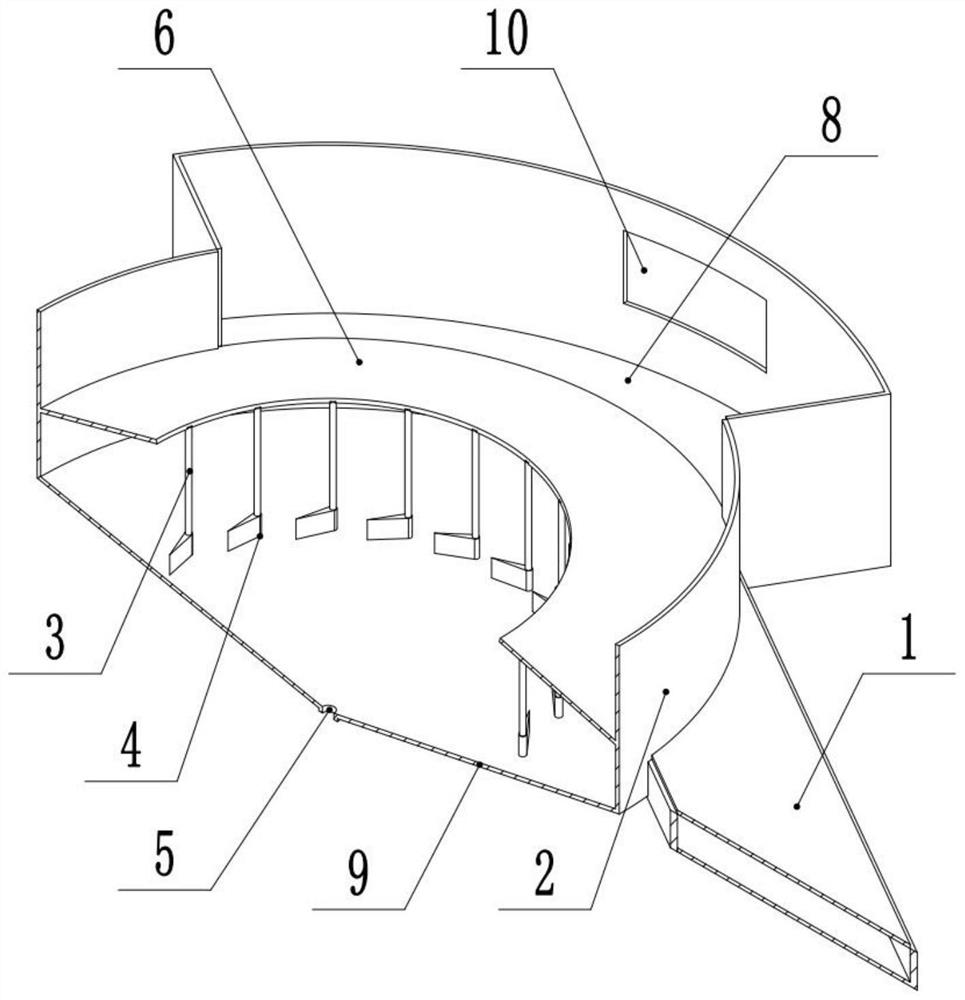

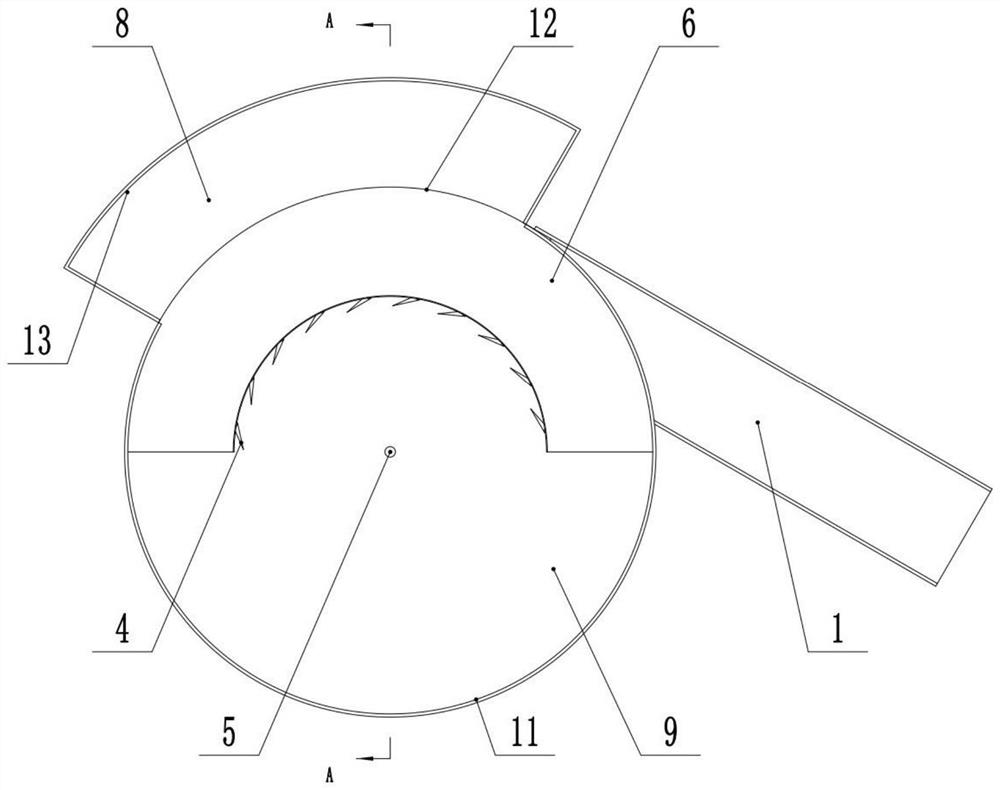

[0022] Such as Figure 1-4 A guide vane type sand discharge funnel is shown, which is used to optimize the sand discharge funnel technology for the treatment of suspended sediment-laden water flow. The guide vane type sand discharge funnel is provided with a guide vane on the column, and the guide vane changes the flow direction of the high-concentration sandy water flow at the bottom of the funnel chamber. The movement path of the sand-carrying water flow is changed, and the sand-laden water flow can quickly enter the spiral flow area in the center of the funnel under the joint action of the guide vane and inertial force for spiral motion. Affected by the rotation of the air vortex, the sand in the spiral flow area is not easy to deposit on the bottom plate or escape with the overflow, and can only be discharged from the sand discharge botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com