Full-bore infinite-order fracturing well completion assembly and technological method thereof

A full-bore, infinite-stage technology, applied in wellbore/well components, earthwork drilling, wellbore/well valve devices, etc., can solve complex procedures, failure of sliding sleeves to open normally, missing fracturing intervals, etc. To solve the problem, achieve the effect of simple process, meet the requirements of selective water control production or secondary fracturing construction, and improve fracturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

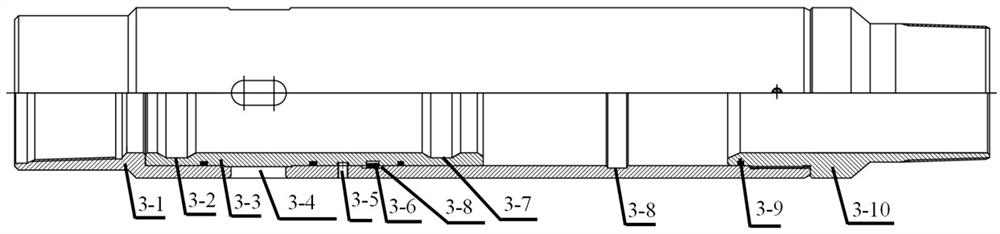

[0059] refer to figure 1 , Figure 1a' , Figure 1b' , figure 2' , Figure 2a , image 3 and Figure 3a As shown, the full-bore infinite-stage fracturing completion assembly includes the fracturing completion sleeve and the opening tool for opening the fracturing completion sleeve. Wherein, the fracturing completion sliding sleeve includes a fixed outer sleeve 3-1 and an inner sliding sleeve 3-3 connected to the inner wall of the outer sleeve 3-1 through shear pins 3-5, the outer sleeve 3-1 and the inner sliding sleeve 3-3 Positioning pieces 3-6 are also arranged therebetween. Among them, sandblasting holes 3-4 (6-10 evenly distributed) and 2 positioning grooves 3-8 connected with the inner cavity are arranged on the outer casing 3-1, and a closing recess is arranged on the upper part of the inner sliding sleeve 3-3. The groove 3-2 is provided with an opening groove 3-7 at the lower part, and a plurality of sealing elements 3-9 are provided in the middle. The overcoat...

Embodiment 2

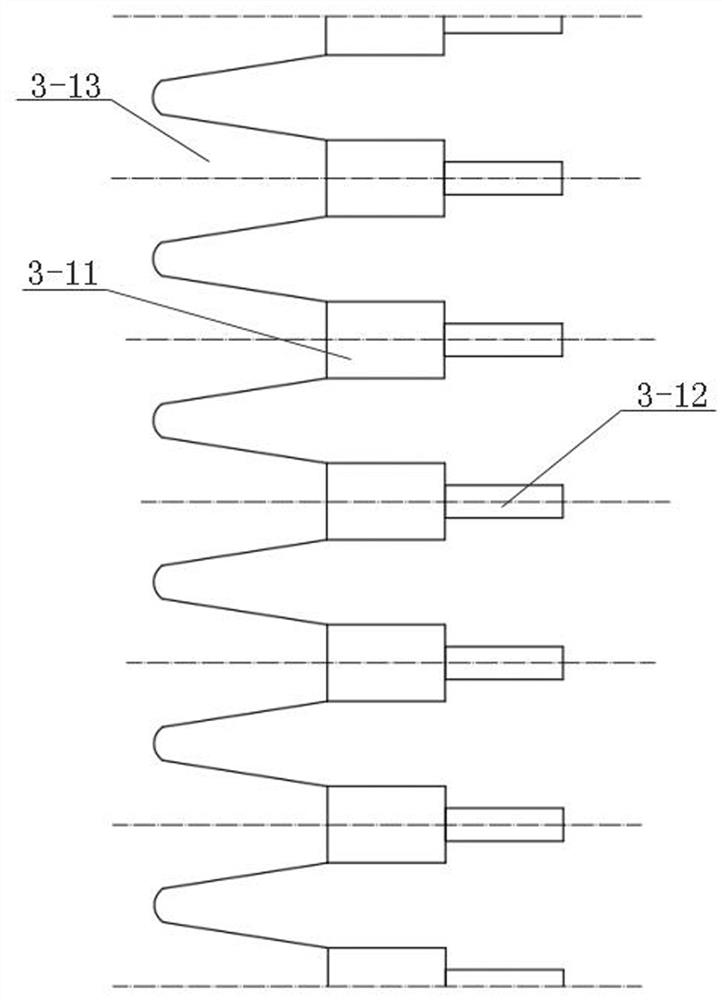

[0075] refer to figure 1 , Figure 1a , Figure 1b , figure 2 , Figure 2a and Figure 2b As shown, as a preferred embodiment, it is basically the same as Embodiment 1, except that the opening groove 3-7 includes a guide opening 3-13, a slider groove 3-11 and a guide groove 3-12. Wherein, the guide opening 3-13 is tapered and is connected with the slider groove 3-11 and the guide groove 3-12, the slider groove 3-11 cooperates with the opening slider 13-6, and the guide groove 3-11 is matched with the opening slider 13-6. 12 cooperates with guide key 13-8. Also be provided with connecting piece 13-7 between tool lower joint 13-9 and central pipe 13-4, form for opening slide between connecting piece 13-7 and tool upper joint 13-2 and central pipe 13-4. Block 13-6 carries out the limit groove of radial limit. A pressure cap 13-10 is provided between the connector 13-7 and the tool lower joint 13-9, and a plurality of guide keys 13-8 extending from the outer surface of the...

Embodiment 3

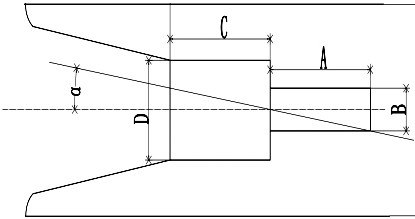

[0083] It is basically the same as Embodiment 1, the difference is that there are multiple opening grooves 3-7, which are distributed in a 360° spiral at the lower part of the inner sliding sleeve 3-3, and the opening groove 3-7 is connected with the inner sliding sleeve 3-3. The 3-axis has an inclination angle α, and the inclination angle α is 0-60°.

[0084] There are multiple first seals 3-9, the first seal 3-9 and the second seal 13-3 are rubber sealing rings, and the first seals 3-9 are respectively arranged on the sandblasting holes 3-4, shear Between the pin 3-5 and the positioning piece 3-6. The positioning members 3-6 in each embodiment are elastic positioning members.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com