Joint for fiber optical cable pipeline

An optical cable connector and fiber technology, applied in the field of fiber optic cable connectors, can solve problems such as damage and difficult removal of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

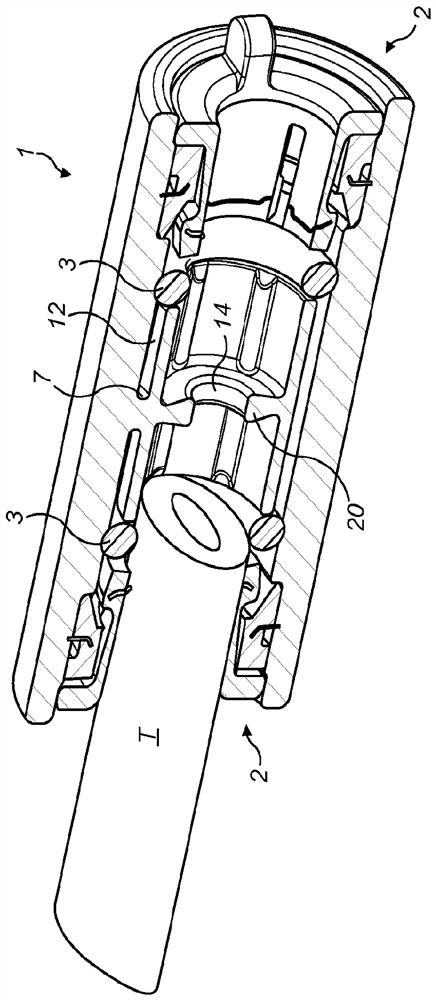

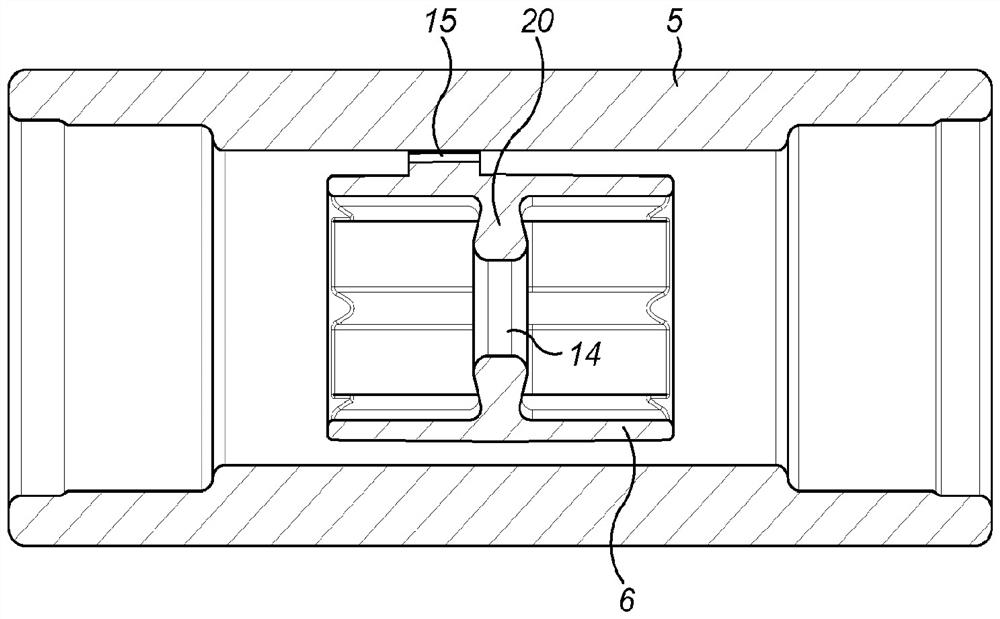

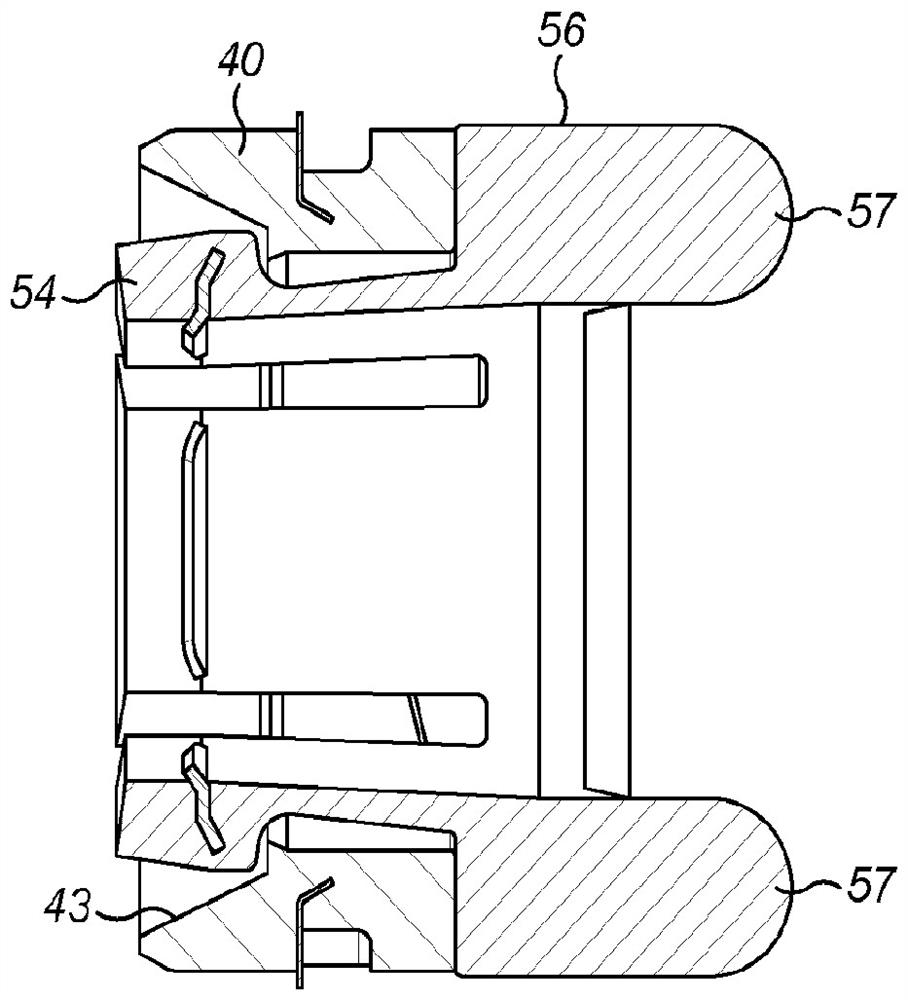

[0047] The connector includes a connector body 1 having a generally hollow cylindrical configuration centered on the main axis X. A connector 2 (described in more detail below) is provided at each end to receive and grip a tube T sealed by an O-ring 3 at each end.

[0048] The body 1 is moulded from non-opaque plastic. The plastic must be sufficiently light-transmitting that external visual inspection of the connector allows the operator to determine if a fiber optic cable or fiber bundle F is present at the center of the connector. Ideally, the body should be as close to transparent as possible. However, practical considerations mean that the ontology will not be completely transparent. Instead, the body may be translucent enough that the fibers are sufficiently visible. Suitable materials are polycarbonate, polystyrene, polyester, acrylic and nylon. The body 1 is formed during the moulding process and can optionally be polished to improve the light transmission of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com