Method for producing electronic component

A technology of electronic components and resistors, applied in nanotechnology for sensing, manufacturing resistors through photolithography, resistor manufacturing, etc., can solve problems such as poor yields

Pending Publication Date: 2022-06-21

INFINEON TECH AG

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This leads to poor yields in subsequent d

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

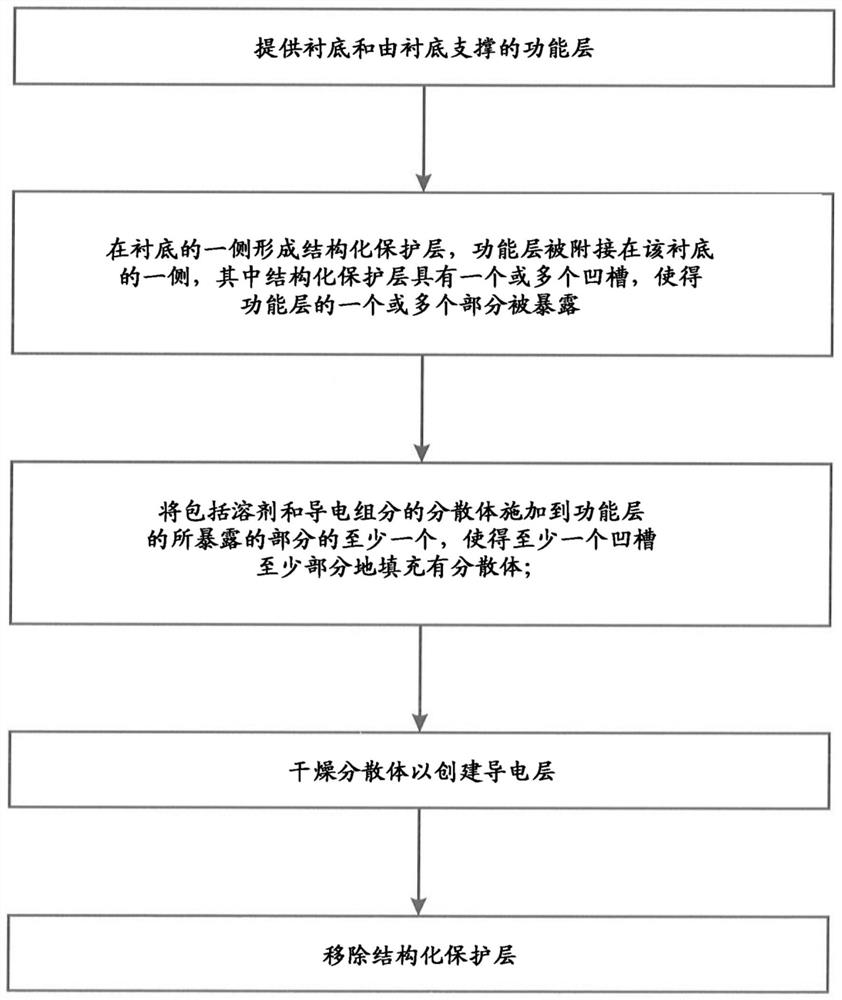

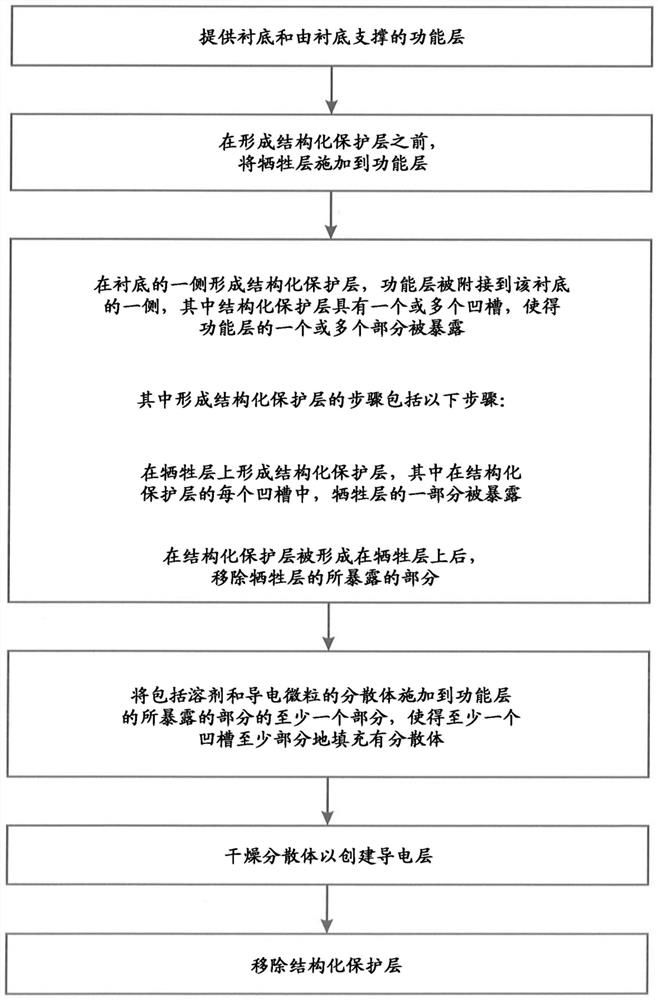

Embodiments of the present disclosure relate to a method for manufacturing an electronic component wherein the method comprises the steps of: providing a substrate and a functional layer supported by the substrate; forming a structured protective layer on one side of the substrate, the functional layer being attached to one side of the substrate, where the structured protective layer has a recess such that a portion of the functional layer is exposed; applying a dispersion comprising a solvent and a conductive component to the exposed portion of the functional layer such that the recess is at least partially filled with the dispersion; drying the dispersion to create a conductive layer; and removing the structured protection layer.

Description

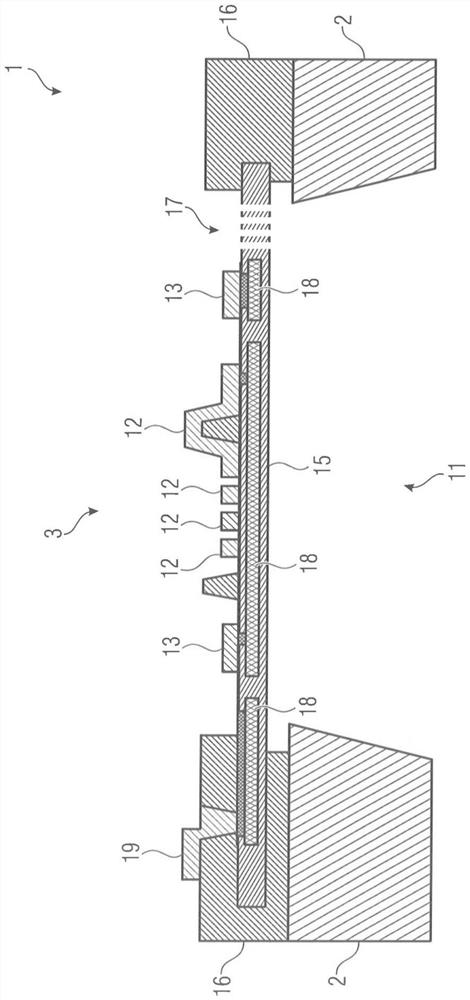

technical field [0001] Embodiments relate to a method for manufacturing an electronic component. More specifically, embodiments relate to a method for manufacturing an electronic component, wherein a dispersion is applied to a functional layer and dried to create a conductive layer. Background technique [0002] Obtaining a conductive layer with a defined pattern by applying and drying the dispersion is a challenge when using selective deposition techniques such as inkjet printing. In particular, the accumulation of material on the edges of the pattern of the conductive layer due to the Marangoni effect results in conductive paths surrounding the desired pattern of the conductive layer. This results in poor yields in subsequent devices such as chemi-resistive gas sensors. [0003] Therefore, there is a need for an improved method for manufacturing electronic components. SUMMARY OF THE INVENTION [0004] This problem is solved by a method for manufacturing electronic com...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): G01N27/12

CPCG01N27/12G01N27/128G01N27/22B82Y15/00G01N27/125G01N27/129G01N27/123C23C16/26C23C16/56H01C17/003H01C17/06506

Inventor M·迈耶J·E·阿达蒂·埃斯特维兹A·M·罗斯

Owner INFINEON TECH AG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap