Wind-resistant column structure of large-span maintenance hangar

A wind-resistant column and large-span technology, applied in wind power generation, building structure, building type, etc., can solve problems affecting node stress, design force deviation, node application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

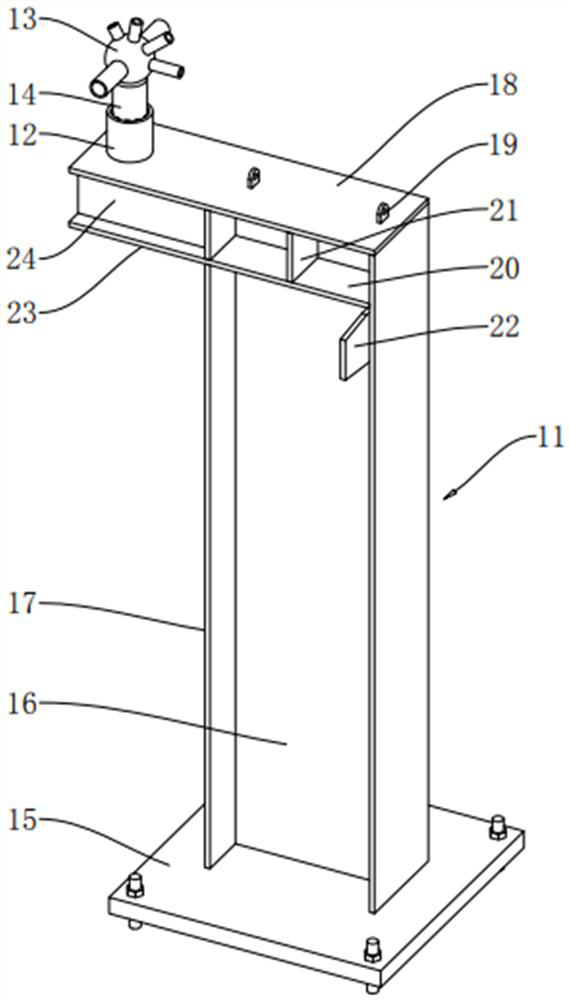

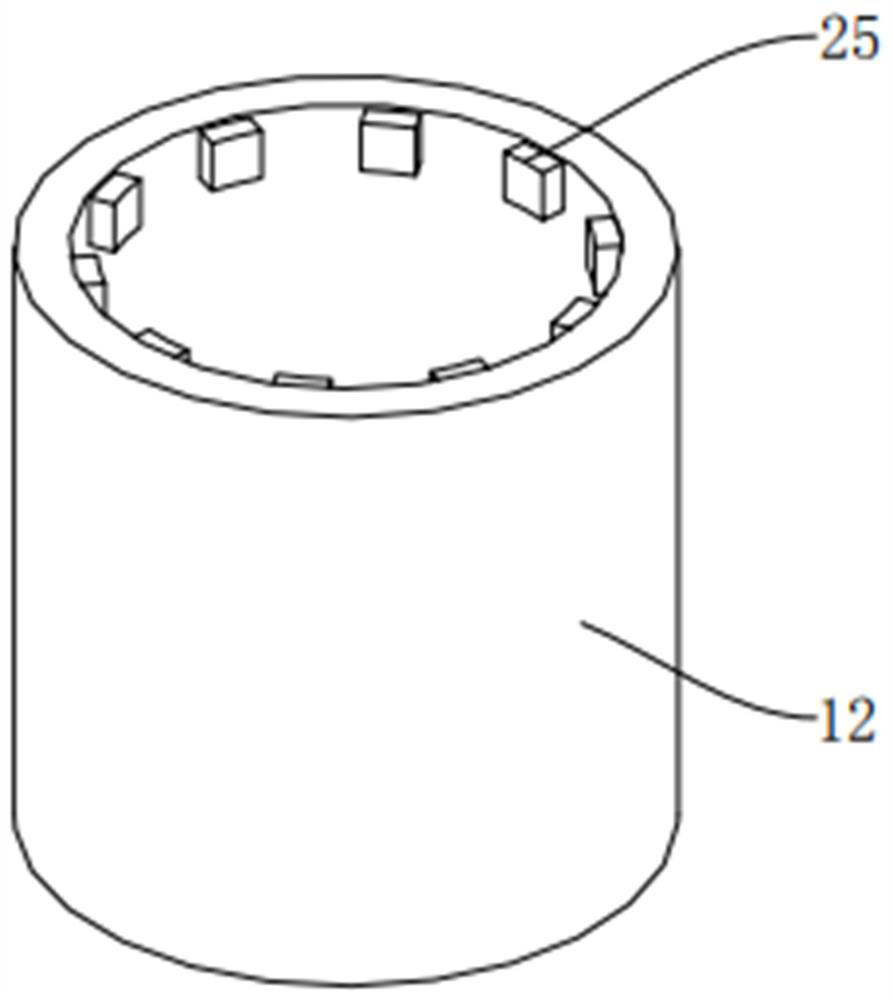

[0038] like figure 2 As shown, the wind-resistant column structure of the large-span maintenance hangar includes a column body 11, an outer support tube 12 connected above the column body 11, and an inner support tube 14 connected below the node 13. The inner support tube 14 is inserted into the outer support tube 12. Inside.

[0039] like figure 2 As shown, the column 11 includes a bottom plate 15, a neutral plate 16 vertically fixed above the bottom plate 15, and two side vertical plates 17 vertically fixed above the bottom plate 15. The neutral plate 16 is welded and fixed and the side vertical plates 17 are perpendicular to the neutral plate 16 . The upper end of the neutral plate 16 is provided with an upper horizontal plate 18 parallel to the bottom plate 15 . Two lifting lugs 19 with holes are welded and fixed on the upper horizontal plate 18 . A lower horizontal plate 20 is welded and fixed on both sides of the neutral plate 16 at a position below the upper horiz...

Embodiment 2

[0044] like Figure 4 As shown, the wind-resistant column structure of the large-span maintenance hangar includes a column body 11, an outer support tube 12 connected above the column body 11, and an inner support tube 14 connected below the node 13. The inner support tube 14 is inserted into the outer support tube 12. Inside.

[0045] like Figure 4 As shown, the column body 11 includes a bottom plate 15, a neutral plate 16 vertically fixed above the bottom plate 15, and two side vertical plates 17 vertically fixed above the bottom plate 15. The neutral plate 16 is welded and fixed and the side vertical plates 17 are perpendicular to the neutral plate 16 . The upper end of the neutral plate 16 is provided with an upper horizontal plate 18 parallel to the bottom plate 15 , and the upper horizontal plate 18 is welded and fixed to the neutral plate 16 and the two side vertical plates 17 . Two lifting lugs 19 with holes are welded and fixed on the upper horizontal plate 18 . ...

Embodiment 3

[0048] like Image 6 As shown, the wind-resistant column structure of the large-span maintenance hangar includes a column body 11, an outer support tube 12 connected above the column body 11, and an inner support tube 14 connected below the node 13. The inner support tube 14 is inserted into the outer support tube 12. Inside.

[0049] like Image 6 As shown, the column body 11 includes a bottom plate 15, a neutral plate 16 vertically fixed above the bottom plate 15, and two side vertical plates 17 vertically fixed above the bottom plate 15. The neutral plate 16 is welded and fixed and the side vertical plates 17 are perpendicular to the neutral plate 16 . The upper end of the neutral plate 16 is provided with an upper horizontal plate 18 parallel to the bottom plate 15 . Two lifting lugs 19 with holes are welded and fixed on the upper horizontal plate 18 . A lower horizontal plate 20 is welded and fixed to a position below the upper horizontal plate 18 on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com