Antibacterial glass forming processing device

A technology for forming and processing antibacterial glass, which is applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc. Turn over and fix, convenient for double-sided grinding, good cushioning and protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention;

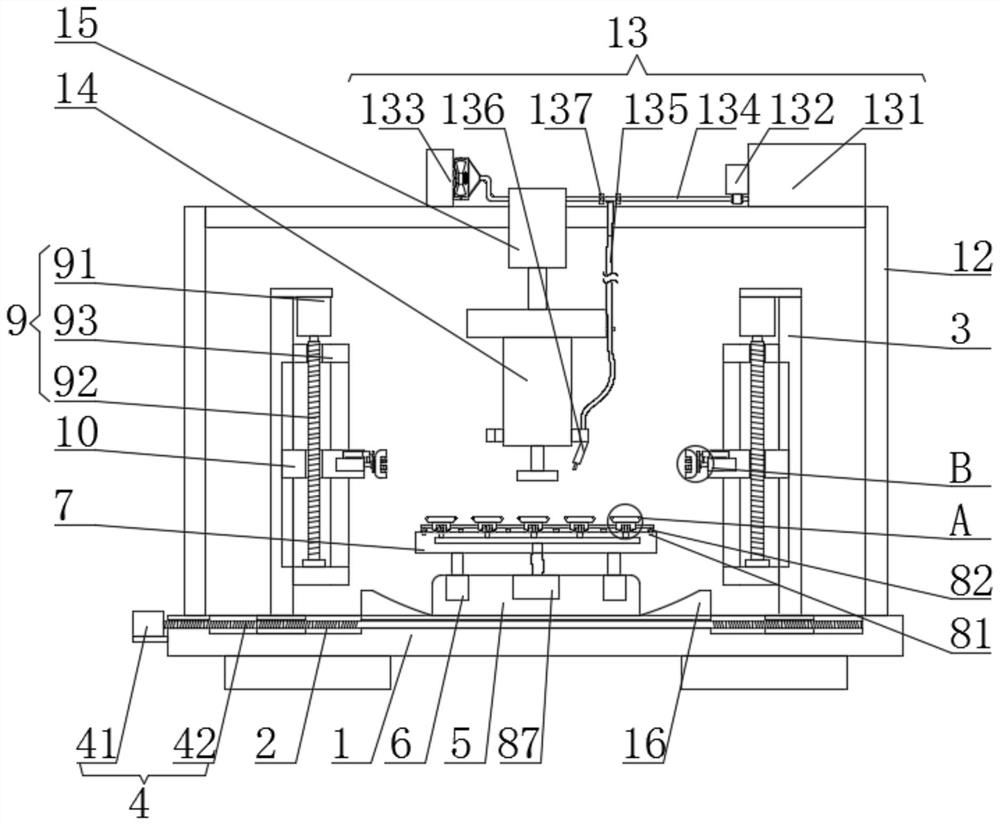

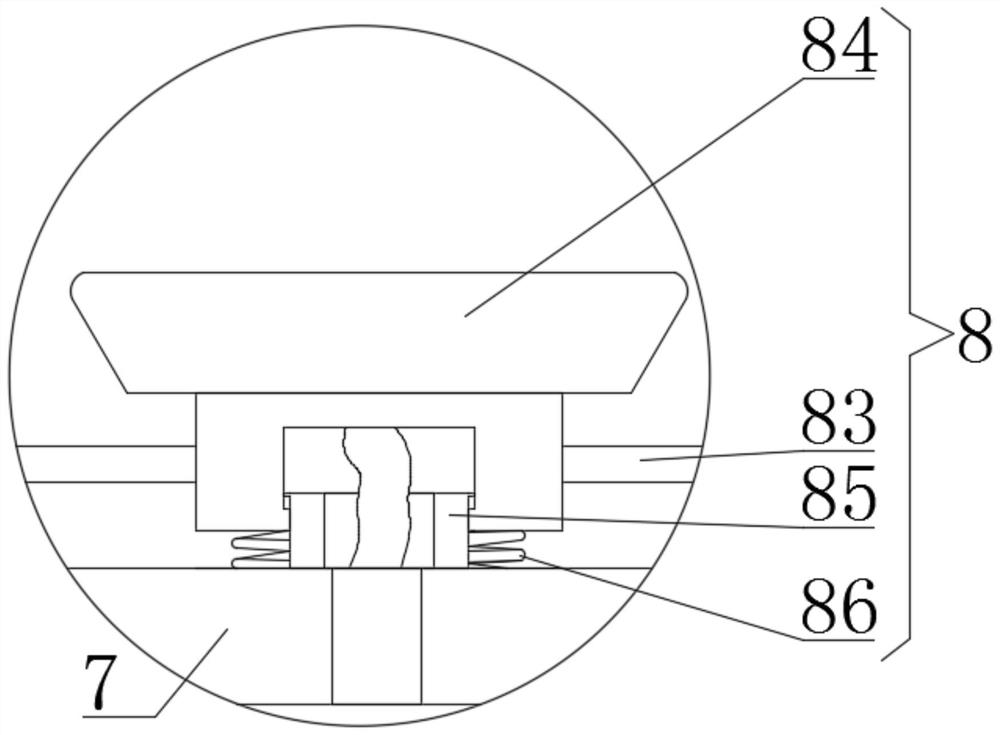

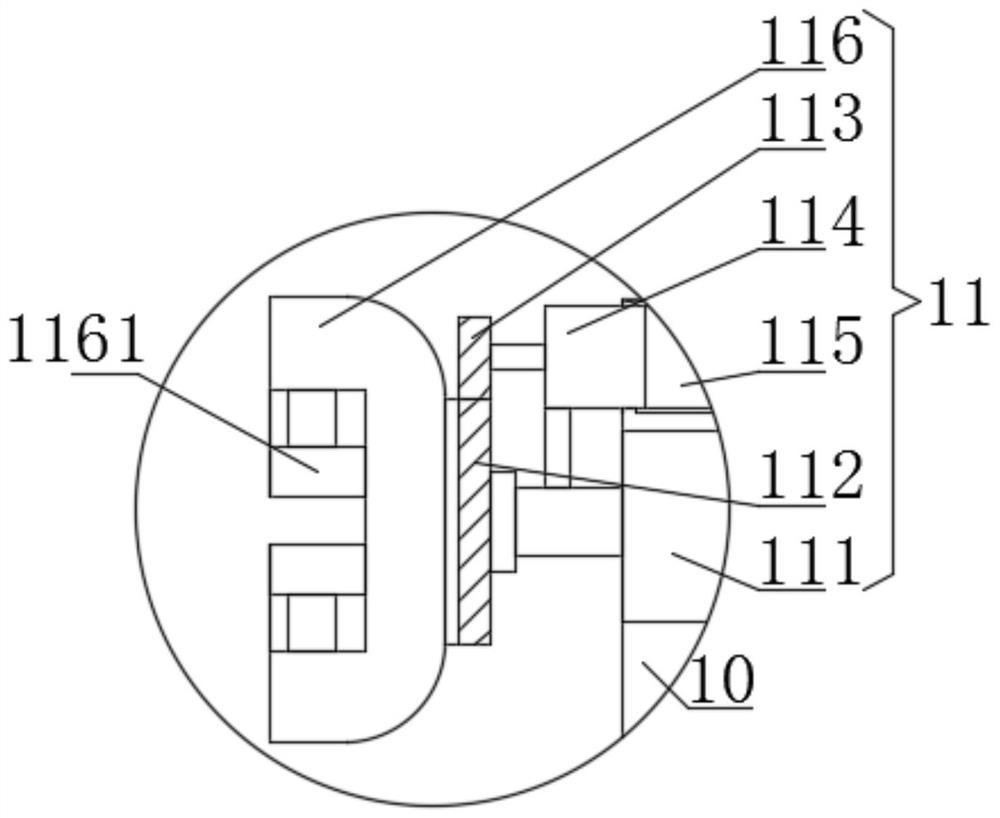

[0025] see Figures 1 to 6 , In the present invention, an antibacterial glass forming and processing device includes a base 1, the top of the base 1 is provided with two chute 2, the two chute 2 are slidably connected with a support column 3, between the two chute 2 An adjustment assembly 4 is installed in the interior, and the adjustment assembly 4 is matched with the two support columns 3. The top of the base 1 is fixedly connected with a support base 5, and the top of the support base 5 shown is fixedly connected with two first hydraulic cylinders 6, two A lift table 7 is fixedly connected to the top between the first hydraulic cylinders 6, a buffer adsorption assembly 8 is installed on the lift table 7, a synchronous drive assembly 9 is installed inside the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com