Glue injection tightening machine for dust cover

A technology of tightening machine and dust cover, which is applied in the direction of motor tools, wrenches, screwdrivers, etc., and can solve the problems of the quality influence of the tightening of the dust cover, easy displacement of the dust cover, and no torque output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical features and technical effects of the technical solutions of the present invention clearer, the following will clearly and completely describe the exemplary solutions of the embodiments of the present invention with reference to the accompanying drawings of the specific embodiments of the present invention.

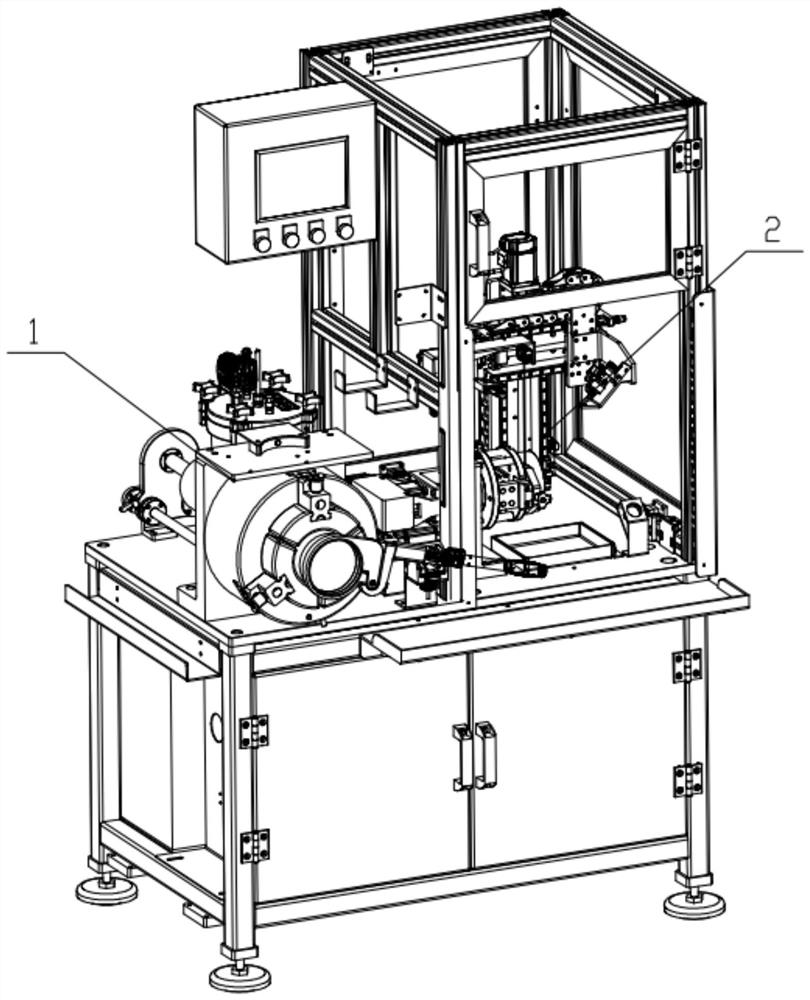

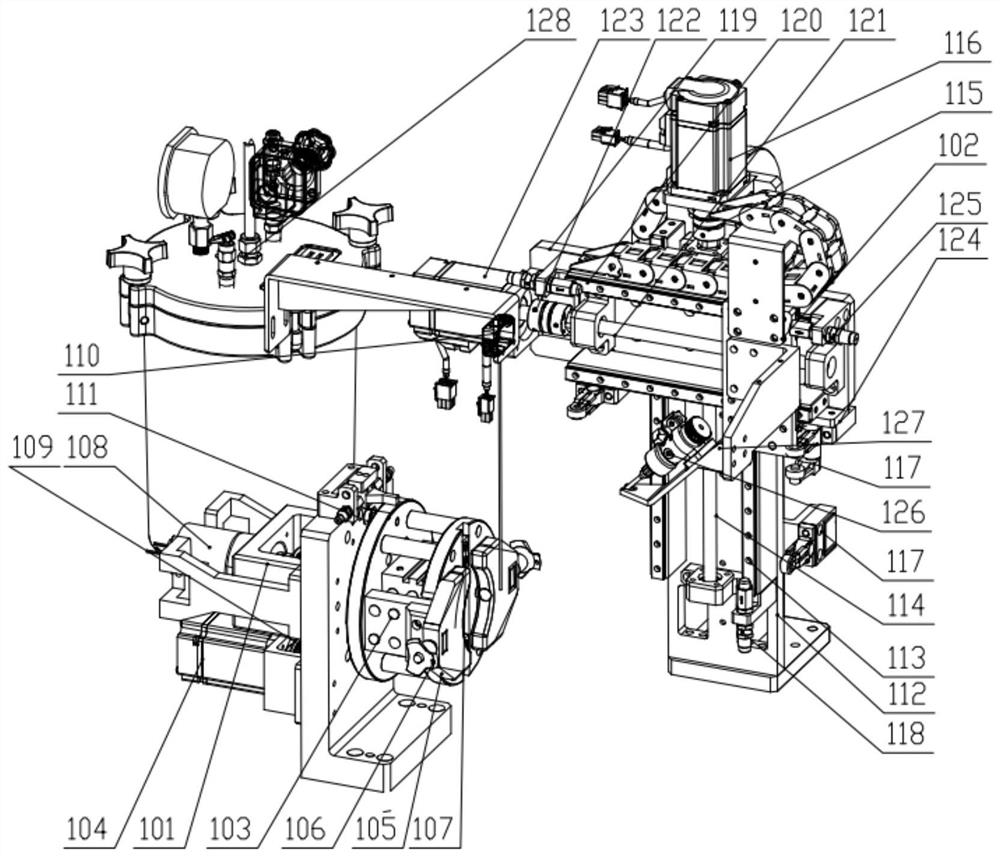

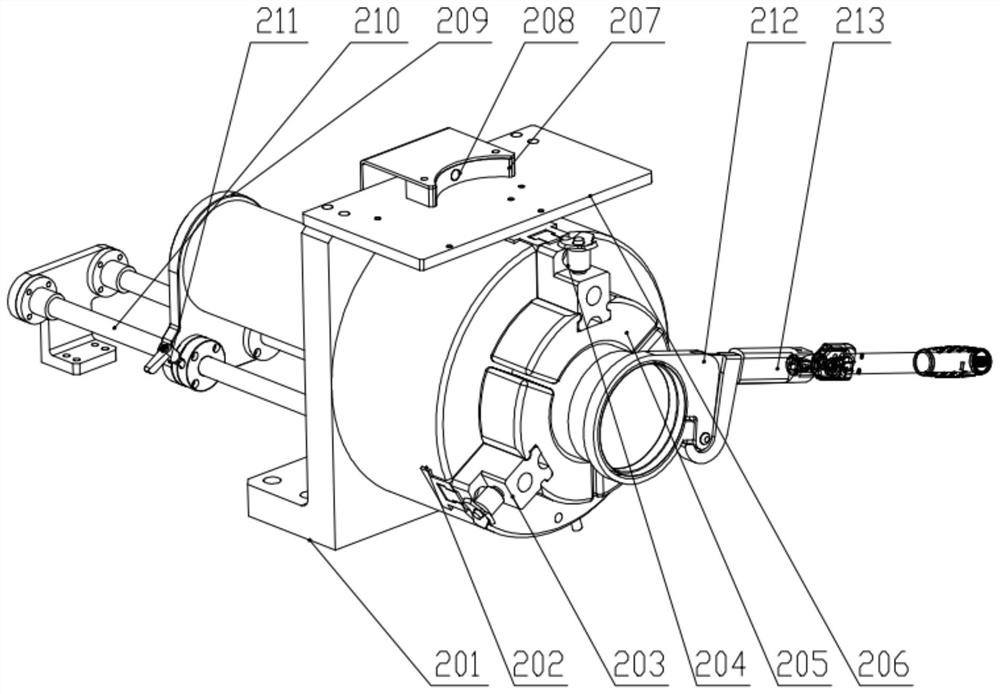

[0033] see Figure 1 to Figure 3 , the application is a dust cover glue injection and tightening machine, including glue injection station 1 and tightening station 2;

[0034] The left side of the glue injection station 1 is the product clamping and rotating mechanism 101, which includes two functions of clamping and rotation. The product clamping is to clamp the product through the clamping tool 105 on the parallel air gripper 103, and different products are replaced with different clamps Tighten the tooling 105, so as to ensure the same clamping stroke of the product concentric and parallel grippers 103, and control the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com