Mounting and positioning structure for wall-mounted heating stove

A technology for installation and positioning of heating furnaces, applied in the field of heating furnaces, can solve problems affecting space utilization, inconvenient shifting, and inability to move, and achieve the effects of convenient inspection, cleaning, and optimized space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

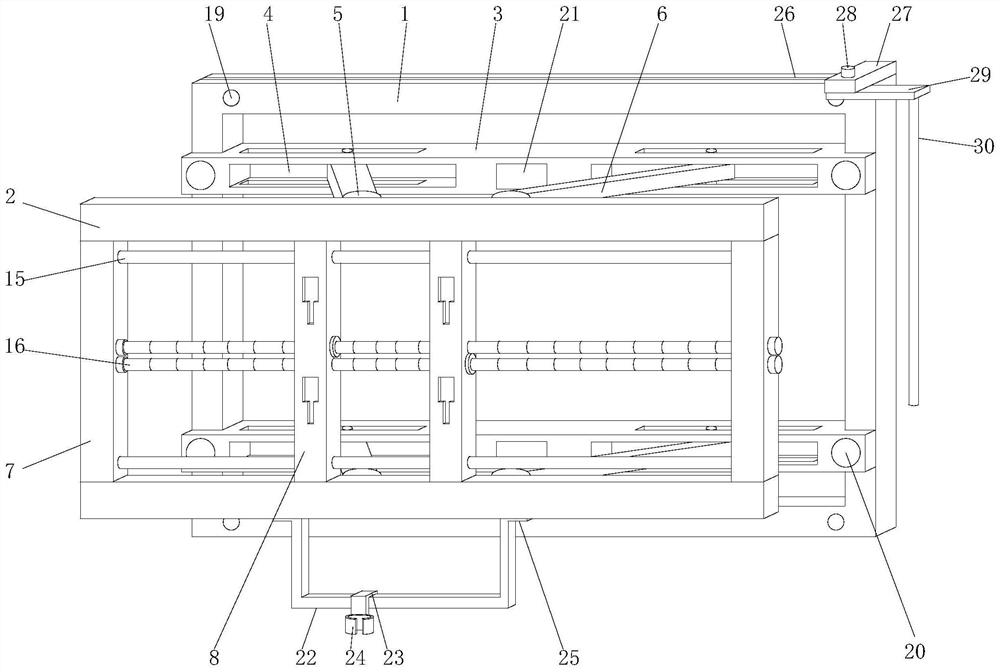

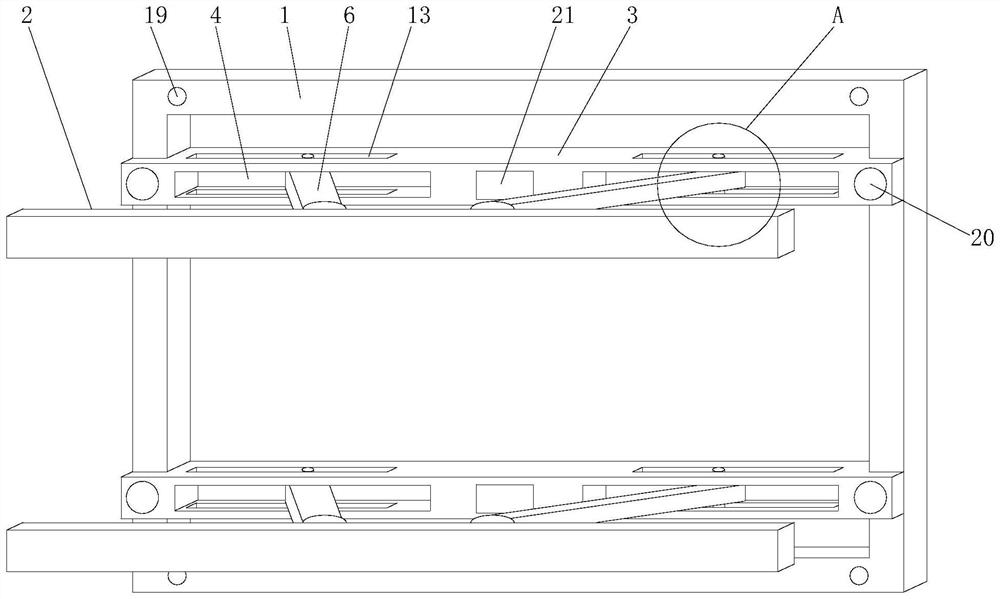

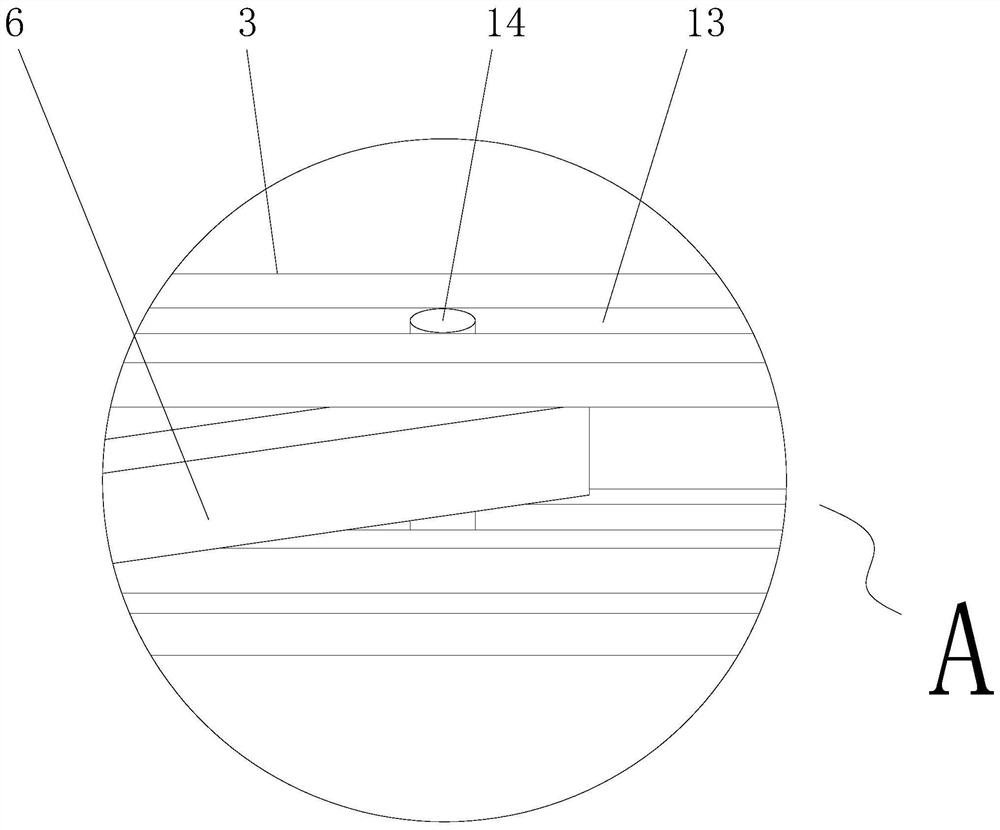

[0030] according to figure 1 , 2 , 3, 4, 5, and 6, this embodiment proposes a mounting and positioning structure for a wall-mounted heating furnace, including a positioning frame 1 and an adjustment frame 2, and the upper and lower ends of the positioning frame 1 are provided with mounting and positioning structures. Frame 3, and both sides of the front end of the mounting frame 3 are provided with movable grooves 4, the adjustment frame 2 is provided with two upper and lower groups, and both sides of the rear end of the adjustment frame 2 of the two groups are provided with shaft plates 5. A support arm 6 is rotatably installed on the shaft plate 5, and the rear ends of the support arms 6 on both sides of the adjustment frame 2 are respectively movably installed with the movable grooves 4 on both sides and are limited by the limiting parts;

[0031] Connecting rods 7 are provided on both sides between the two sets of adjustment frames 2 , and an adjusting portion is provided...

Embodiment 2

[0037] according to figure 1 , 5 As shown, the present embodiment proposes a mounting and positioning structure for a wall-mounted heating furnace, including a positioning frame 1 and an adjusting frame 2. The upper and lower ends of the positioning frame 1 are provided with mounting frames 3, and the front end of the mounting frame 3 is provided with a mounting frame 3. Both sides are provided with movable grooves 4, the adjusting frame 2 is provided with two upper and lower groups, and both sides of the rear end of the adjusting frame 2 of the two groups are provided with shaft plates 5, and the shaft plates 5 are rotatably installed with support Arm 6, the rear ends of the support arms 6 on both sides of the adjusting frame 2 are respectively movably installed with the movable grooves 4 on both sides and are limited by the limiting parts;

[0038] Connecting rods 7 are provided on both sides between the two sets of adjustment frames 2 , and an adjusting portion is provided...

Embodiment 3

[0041] according to figure 1 , 5 As shown, the present embodiment proposes a mounting and positioning structure for a wall-mounted heating furnace, including a positioning frame 1 and an adjusting frame 2. The upper and lower ends of the positioning frame 1 are provided with mounting frames 3, and the front end of the mounting frame 3 is provided with a mounting frame 3. Both sides are provided with movable grooves 4, the adjusting frame 2 is provided with two upper and lower groups, and both sides of the rear end of the adjusting frame 2 of the two groups are provided with shaft plates 5, and the shaft plates 5 are rotatably installed with support Arm 6, the rear ends of the support arms 6 on both sides of the adjusting frame 2 are respectively movably installed with the movable grooves 4 on both sides and are limited by the limiting parts;

[0042] Connecting rods 7 are provided on both sides between the two sets of adjustment frames 2 , and an adjusting portion is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com