Vertical microscope

A microscope, vertical technology, used in microscopes, optics, instruments, etc., can solve problems such as poor operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

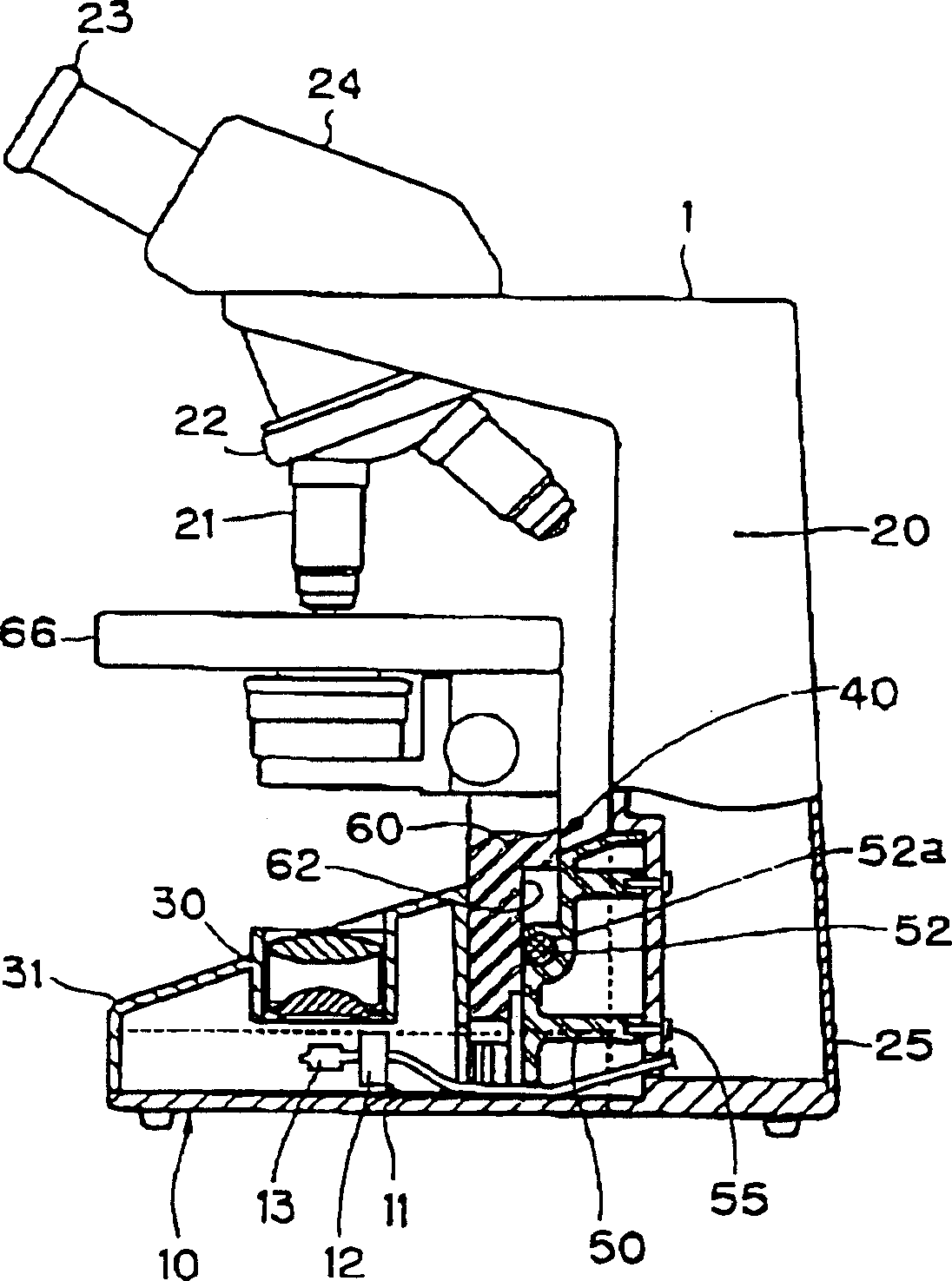

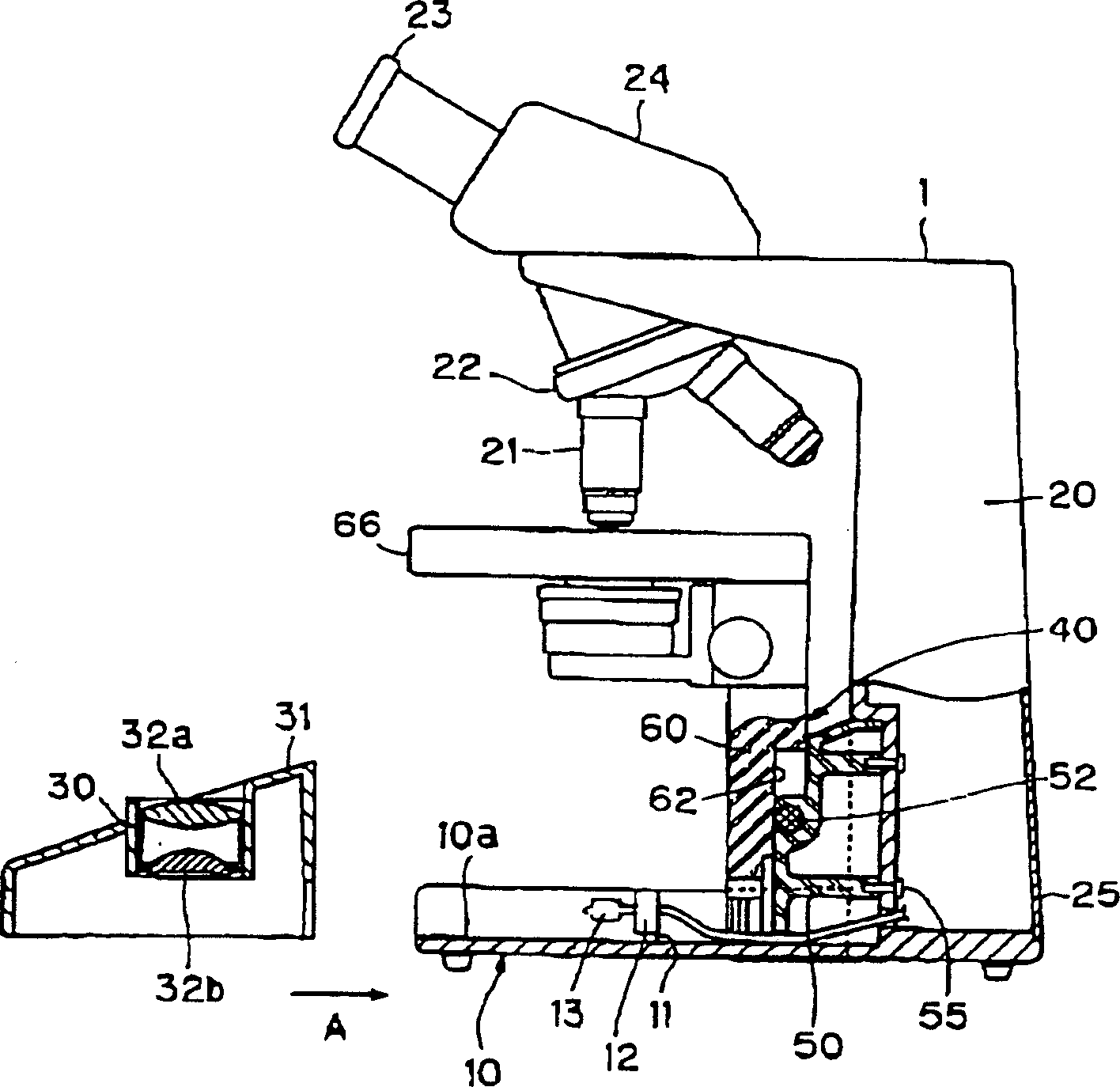

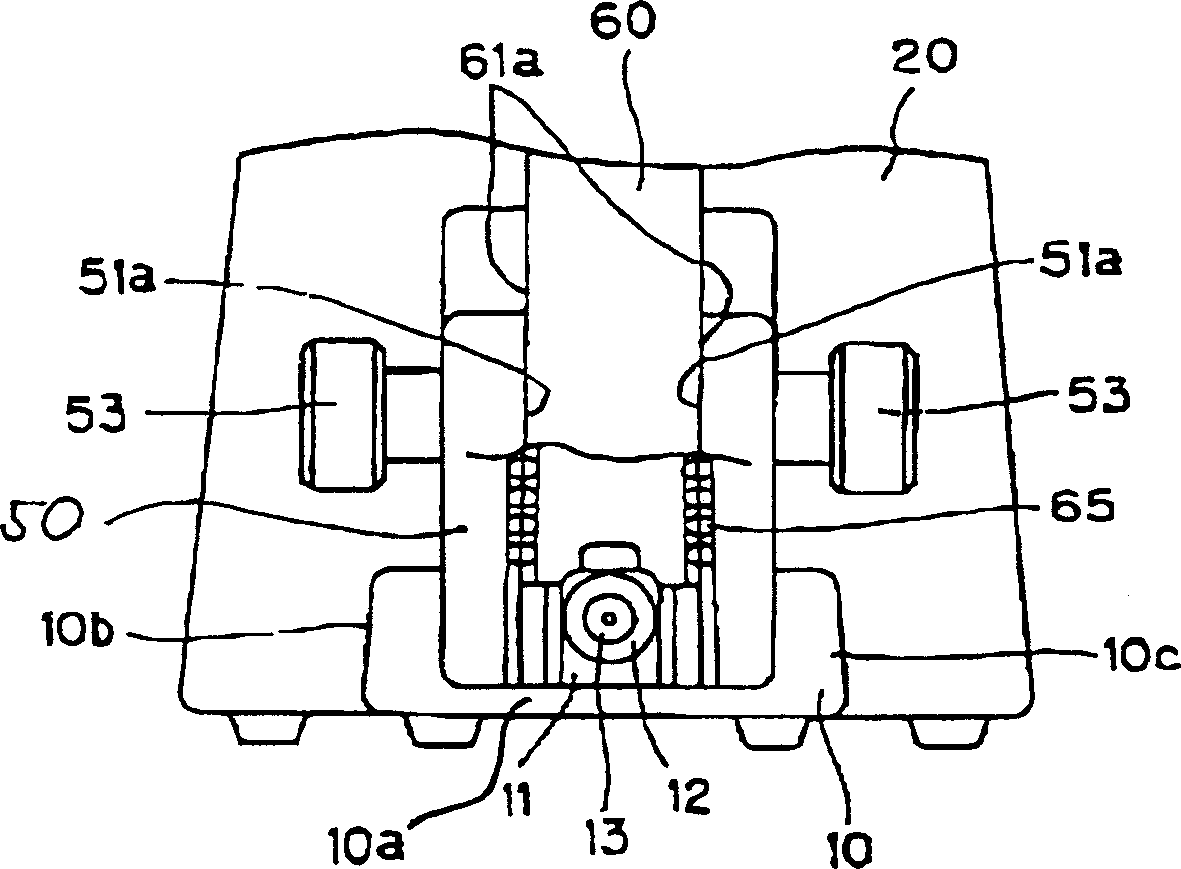

[0035] Hereinafter, an upright microscope according to an embodiment of the present invention will be described with reference to the accompanying drawings.

[0036] figure 1 and 2 is a partially cutaway side view showing an upright microscope according to an embodiment of the present invention, image 3 From figure 2 A partially enlarged view of the upright microscope seen in direction A; Figure 4 yes figure 1 A more detailed side view of the upright microscope shown. Figure 5 and Figure 6 yes Figure 4 A perspective view of an upright microscope is shown; it is worth noting that figure 1 and 5 An upright microscope showing the condenser assembly installed, figure 2 and 6 Indicates an upright microscope with a removable condenser lens assembly.

[0037] An upright microscope 1 includes a base assembly 10 , a mirror frame assembly 20 , a condenser lens assembly 30 and a vertical movement assembly 40 .

[0038] The base assembly 10 includes a base plate 10a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com