Shaving apparatus

A technology of shearing unit and manufacturing method, which is applied in metal processing and other directions, and can solve problems such as not bringing satisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

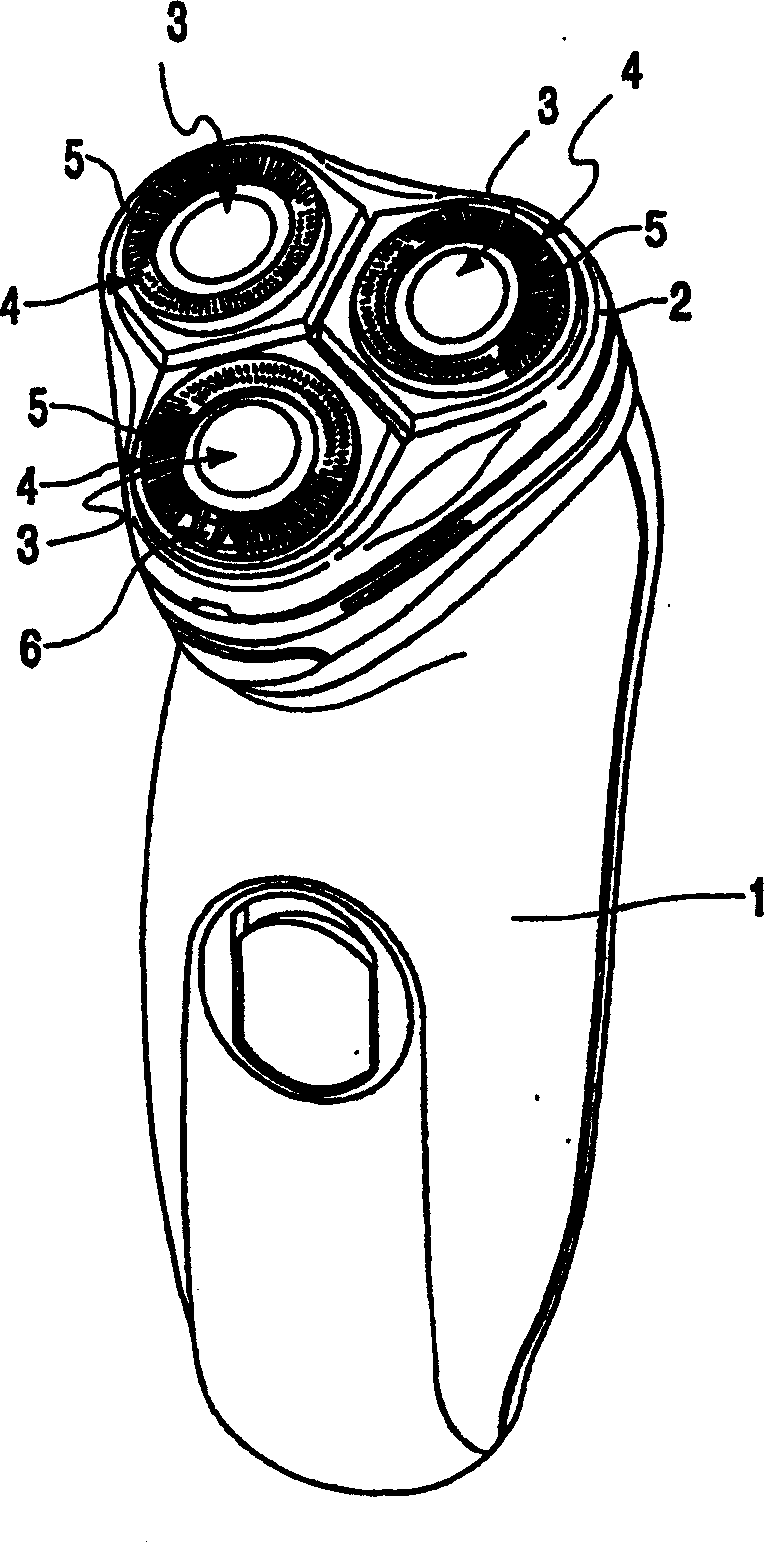

[0015] figure 1 A rotary shaver is shown with a housing 1 and a shaving head holder 2 which is detachable from and / or hinged to the housing. There are three cutting units, also called shaving heads, on the shaving head holder. Each shaving head comprises an outer cutting member 4 with a hair collection opening 5 and an inner hair cutting member 6 driven to rotate relative to the aforementioned elements, the inner hair cutting member is controlled by a An electric motor is driven in a known manner, which is not described in detail.

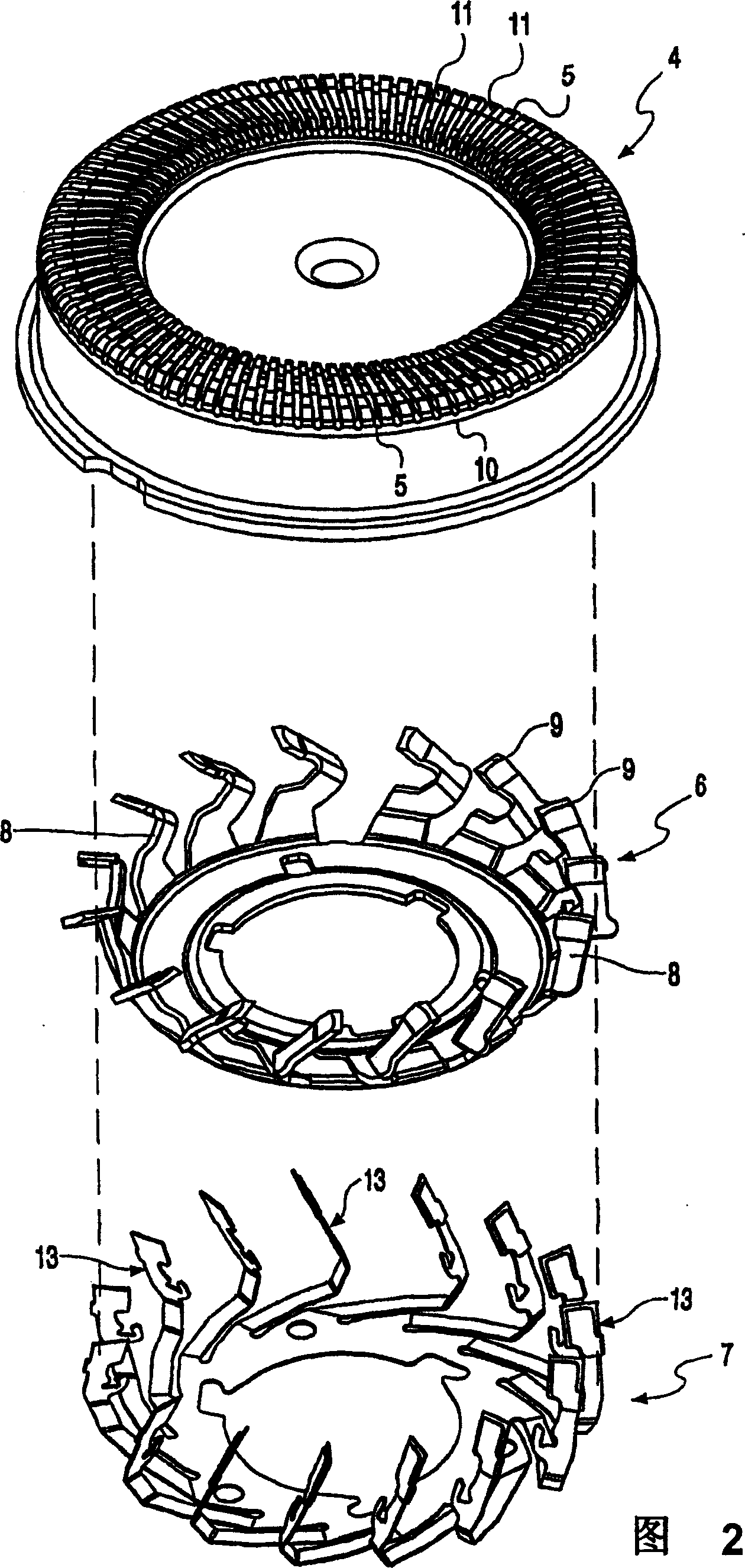

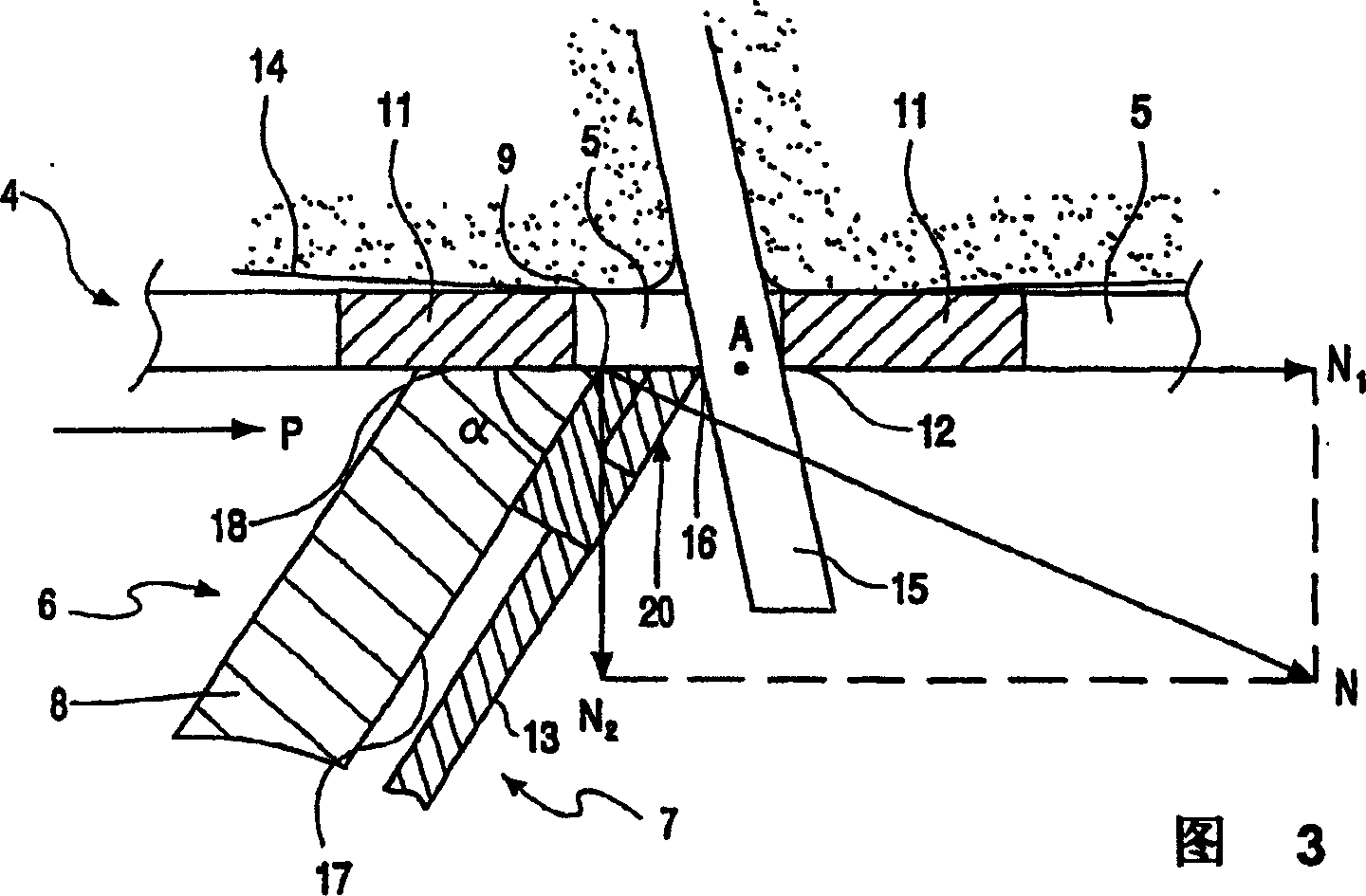

[0016] FIG. 2 shows three parts of the shearing unit 3 , such as an outer shearing element 4 , an inner shearing element 6 and a hair pulling element 7 . The inner shear 6 is a circular body with a plurality of shears 8 each having a cutting edge 9 at its end. The outer shear member 4 shaped as a round cap has a ring wall portion 10, and a plurality of grooved hair collection ports 5 are arranged on the ring wall portion 10. The collection ports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com