Method and device for coiling motor stator

A technology of a motor stator and a winding device is applied in the directions of electromechanical devices, manufacturing of motor generators, electrical components, etc., and can solve the problems such as narrow slot openings and scars of the stator 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

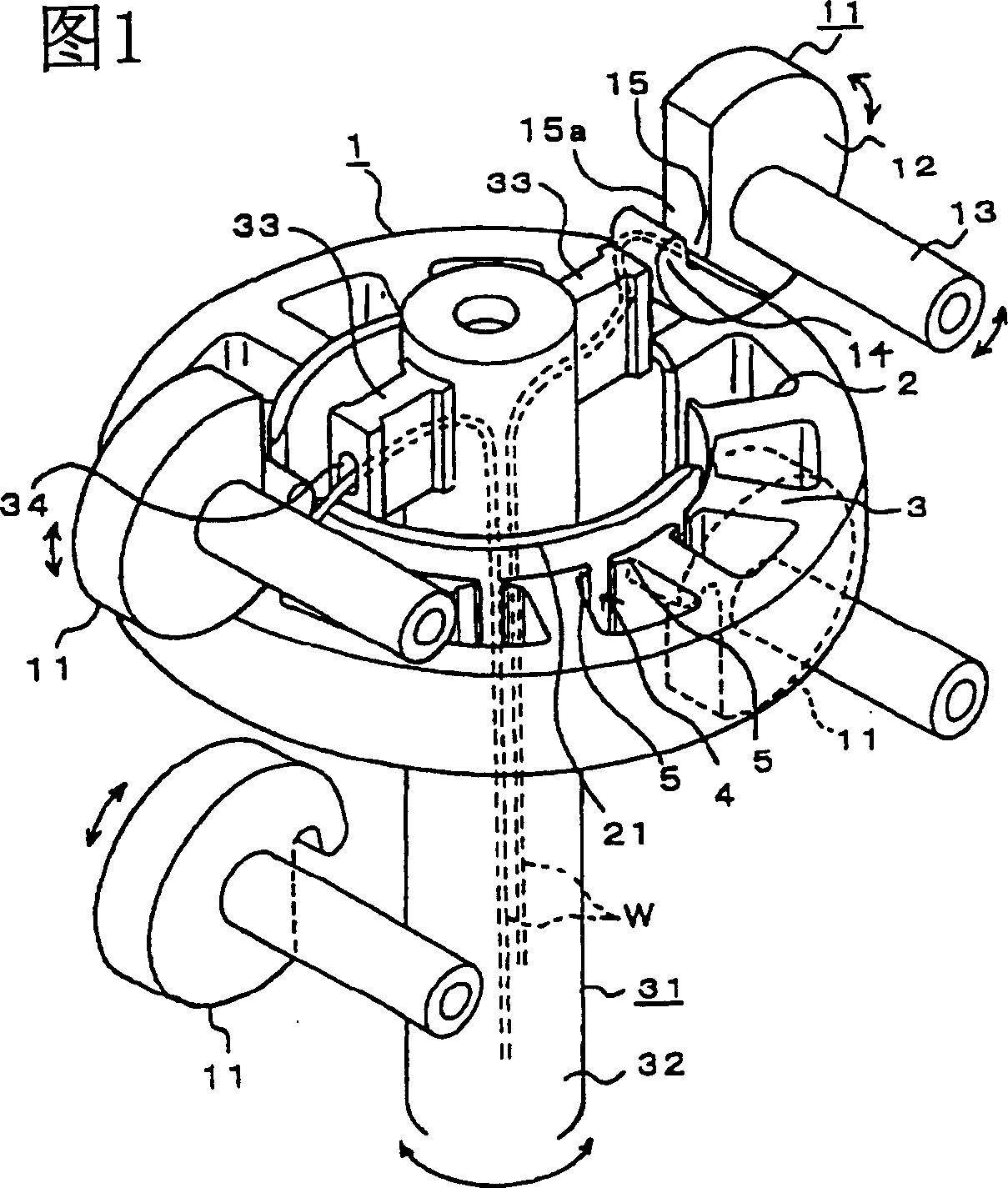

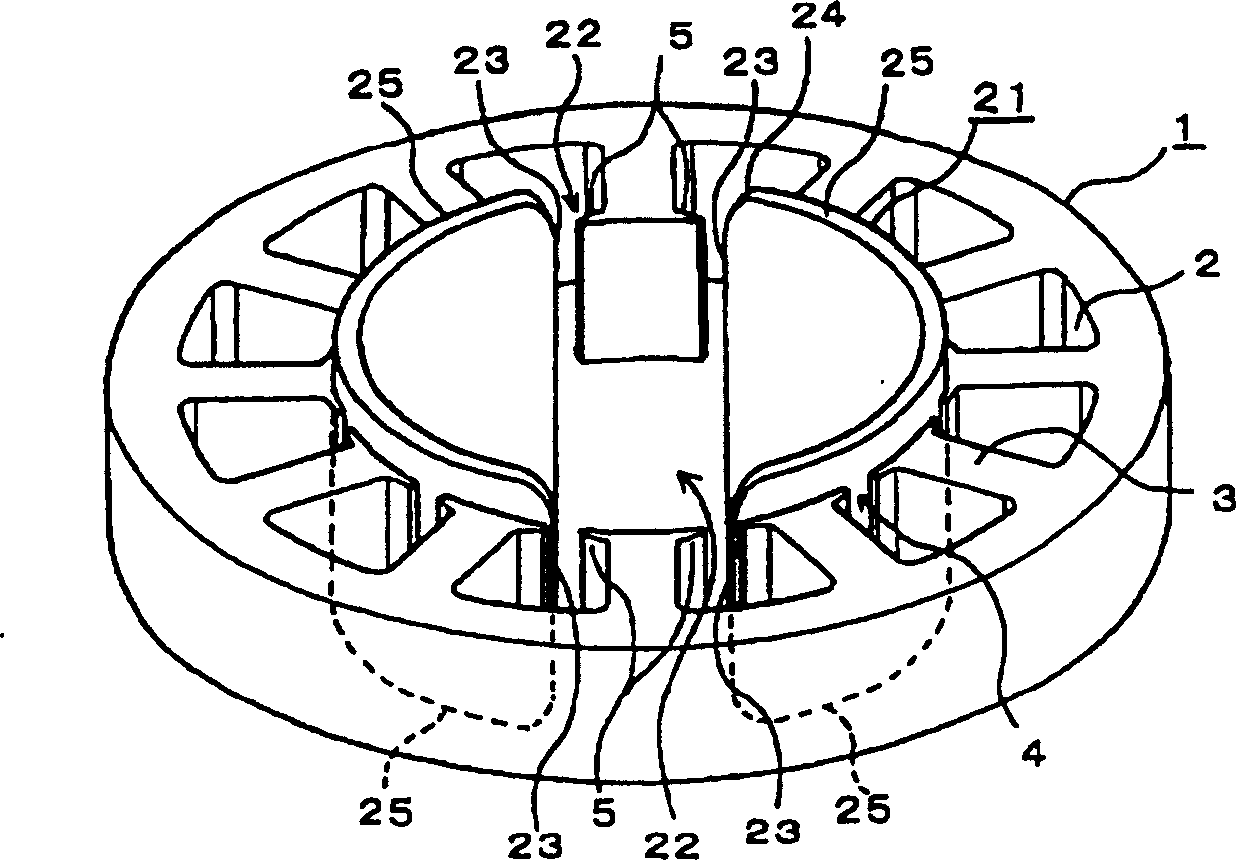

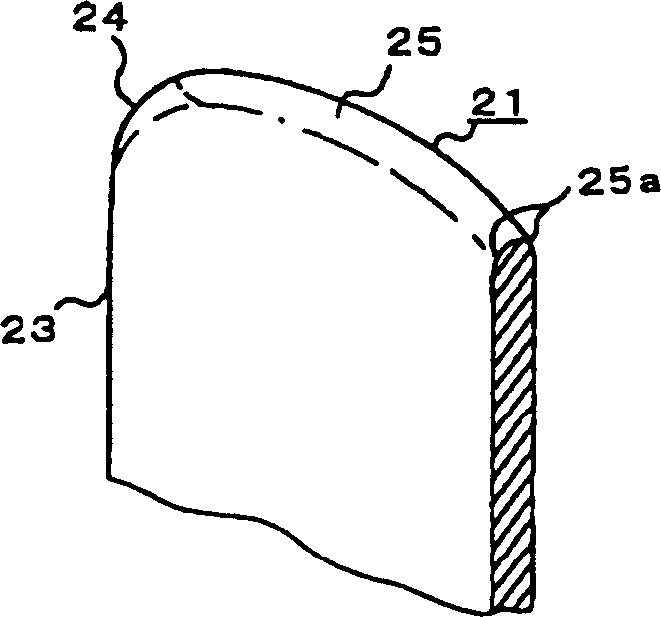

[0034] Below according to Figure 1- Figure 5 A winding device for a motor stator according to an embodiment of the present invention will be described.

[0035] As shown in the figure, the stator 1 of the motor winds the wire W in series on the wound part 3 of the slot 2, as Figure 5 Coils 6 are formed on the respective wound portions 3 as shown. Fig. 1 shows the conveying part of the conveyer 31 of the electric wire W and the wire winder 11 during winding, the shaft 32 of the conveyer 31 is disposed in the central space of the stator 1, and two outlet pipes are arranged radially on the upper part of the shaft 32 33. The above-mentioned protruding length of the outlet pipe 33 can be formed in the central space of the stator 1 with a slight shift away from the slot opening 4 . In the shaft 32 , the electric wire W sent from a winding shaft not shown is inserted therein, and is sent from the opening 34 of the lead-out pipe 33 to the slot 2 of the stator 1 . In FIG. 1 , onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com