Expansion device for telescopic pipe and method for expanding telescopic pipe by using expansion device

A technology of expansion device and telescopic tube, which is applied in the field of expansion device for automatic expansion of telescopic tubes, can solve the problems of cumbersome, time-consuming and labor-intensive telescopic tubes, and reduce operating efficiency, and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

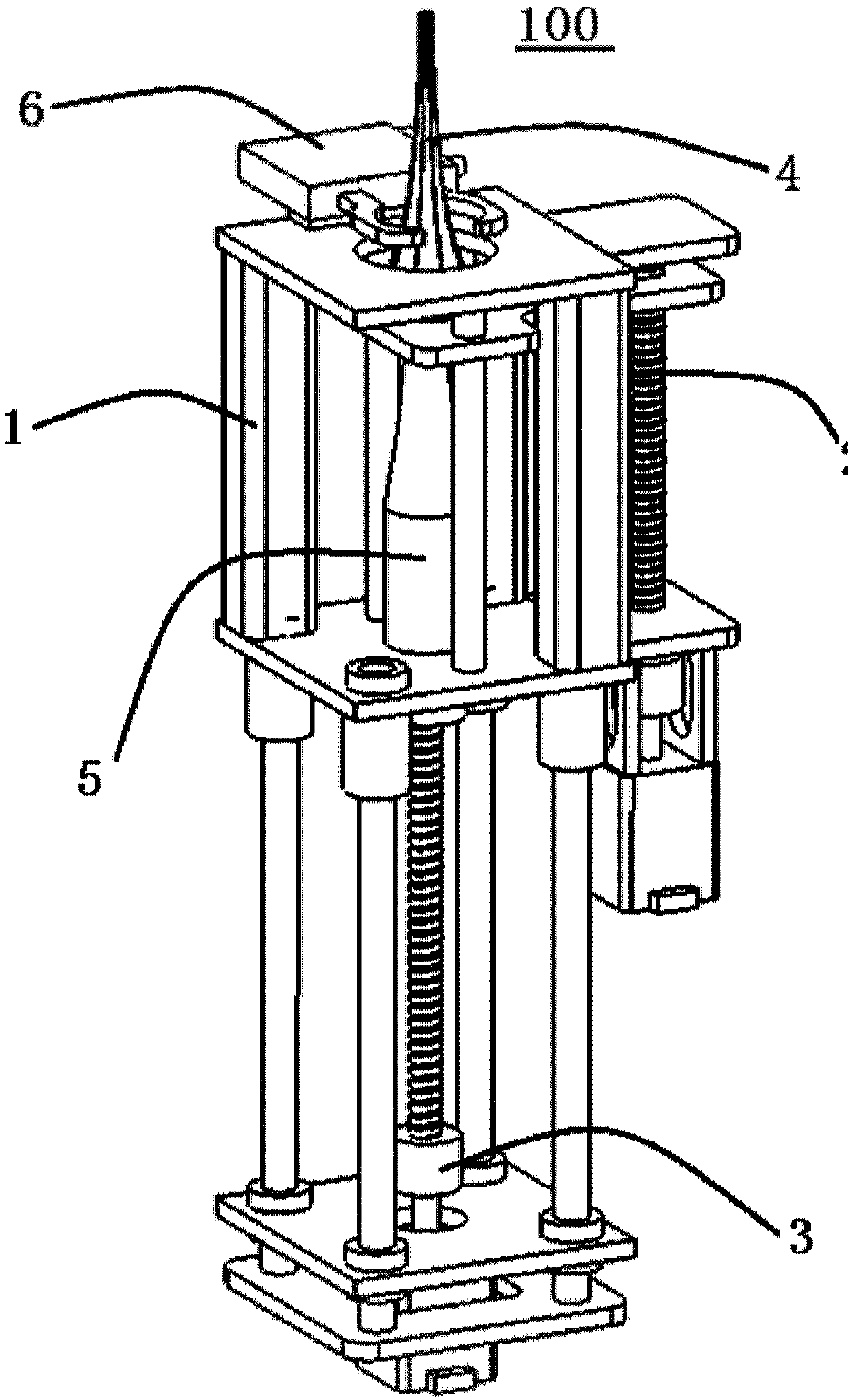

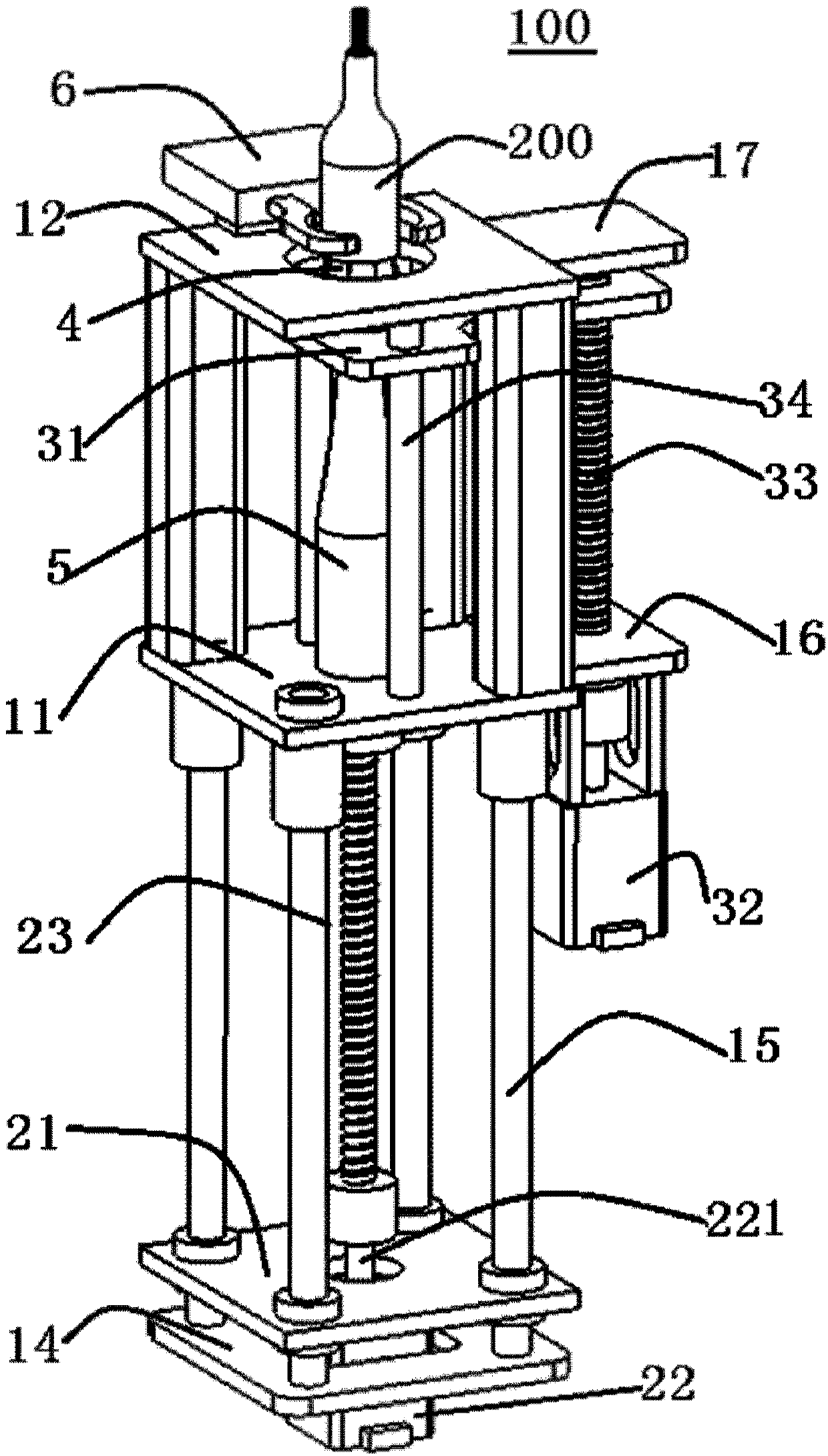

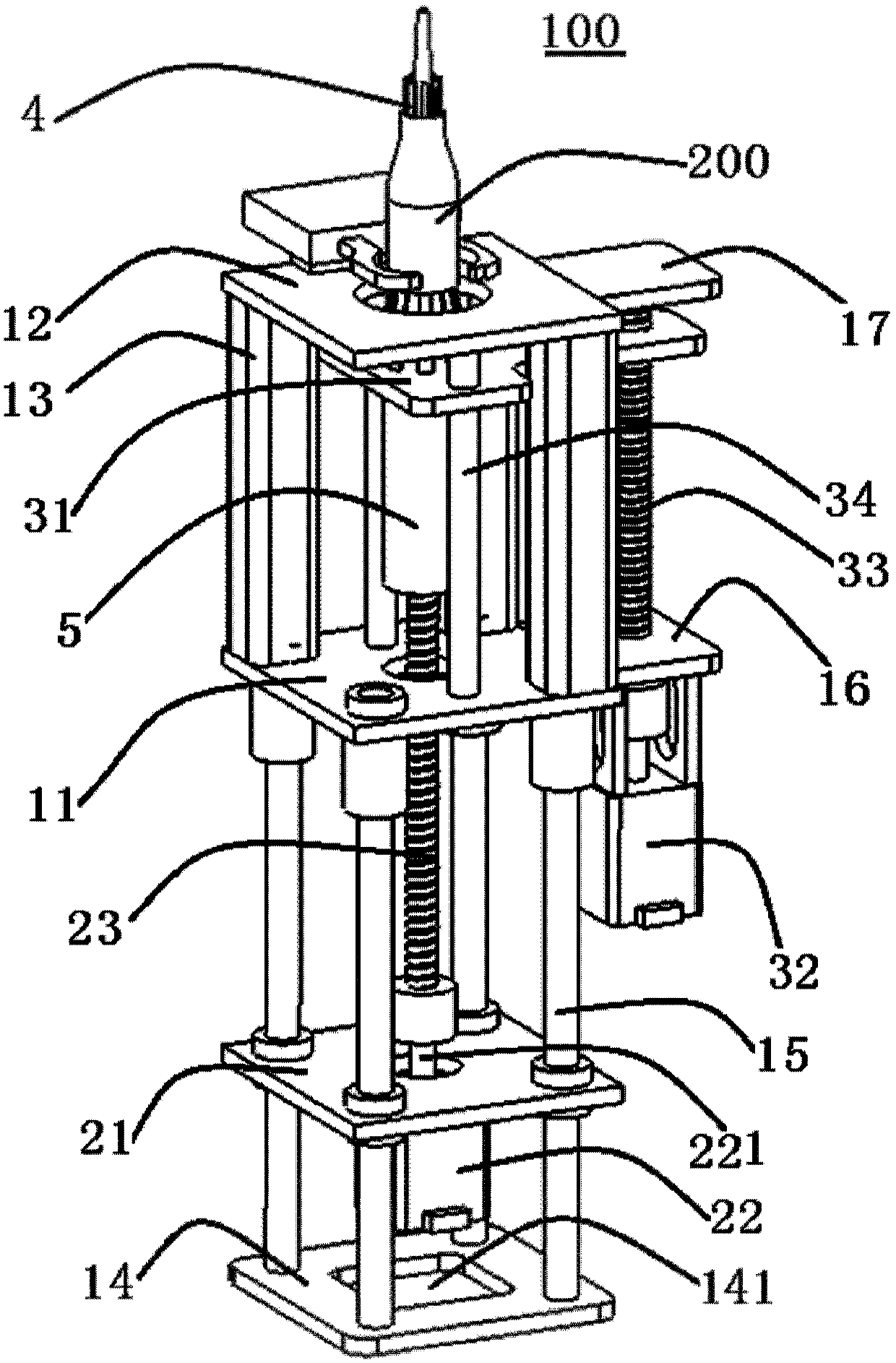

Image

Examples

Embodiment 2

[0084] In an embodiment 2, the fitting cylinder and the expansion tube can be integrated into one part.

[0085] According to another embodiment of the present invention, there is provided a method for expanding the telescopic tube using the expansion device described in any one of the above embodiments, including the following steps:

[0086] Putting the telescopic tube on the expansion member in a state where the expansion member is contracted;

[0087] The first driving device is activated to drive the expansion tube to be gradually inserted into the expansion member to at least partially radially expand the telescoping tube in an axial direction by the expansion member.

[0088] Further method, said method also includes the steps of:

[0089] activating the second driving device to drive the expansion member to withdraw from between the expansion tube and the telescopic tube, so that the expanded telescopic tube remains on the expanded tube; and

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com