Cutter

A tool and tool arm technology, applied in the field of tools with a safety device, can solve the problems that it is difficult to observe the cutting part and the cutting work is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

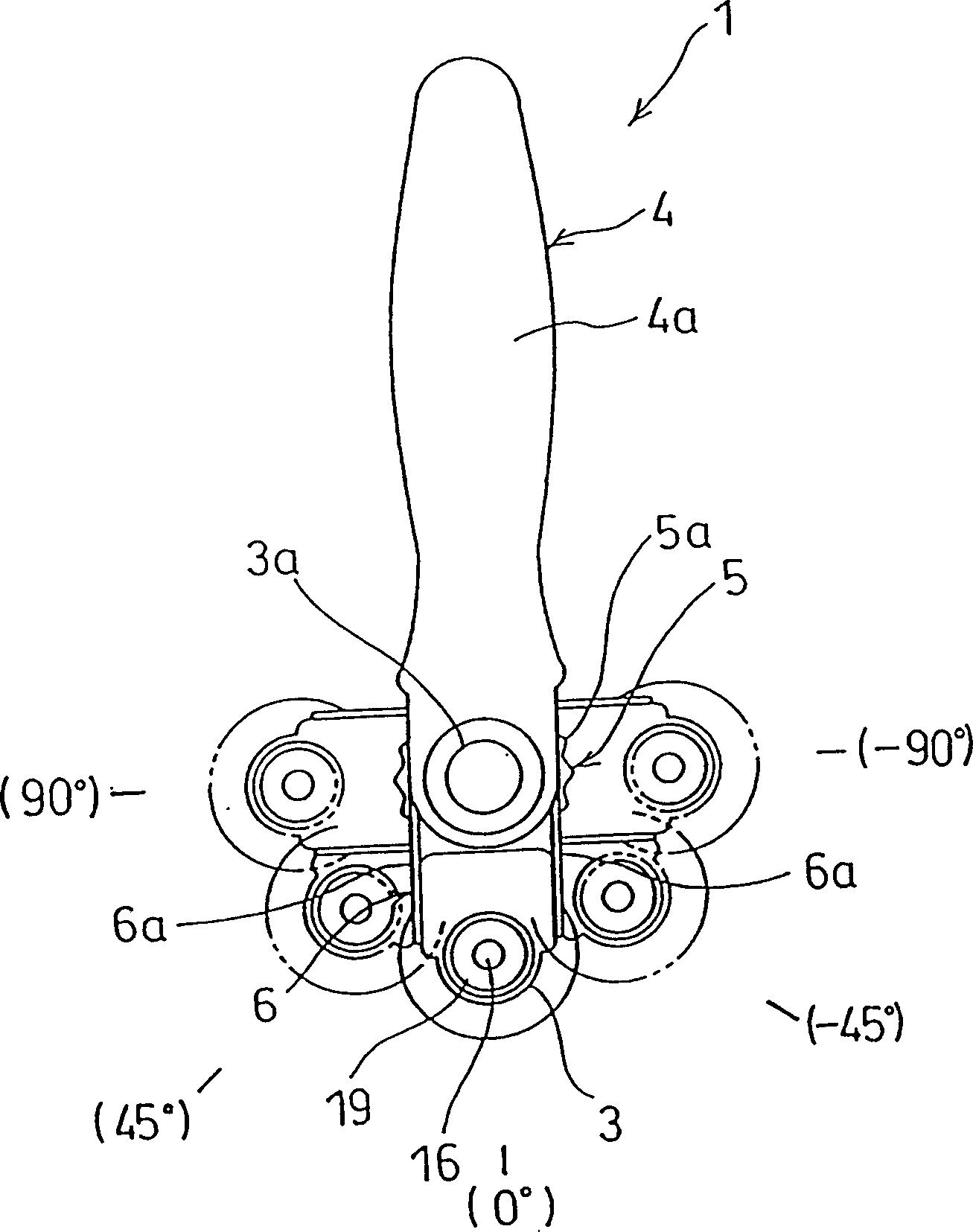

[0027] Embodiments of the cutting tool of the present invention will be referred to Figure 1-14 to explain. First, an overview of the cutter of this embodiment will be given. like figure 1 As shown, the knife 1 of this embodiment includes a knife arm 3 pivotally connected with a rotating blade 2 and a knife handle 4 clamping the knife arm 3, and by pressing the button 3a, the knife arm 3 can be wound around the support of the knife arm 3 The shaft turns and is fixed (or positioned) every 45 degrees. Moreover, the tool 1 is provided with a guard 6, which can move forward or retract backward by rotating a turntable formed on the guard driver 5 (to be explained later), and retract when the guard 6 retracts. state, that is, when the cutter of the rotating blade 2 is not protected, the button 3a will be locked and the rotation of the knife arm 3 will be restricted.

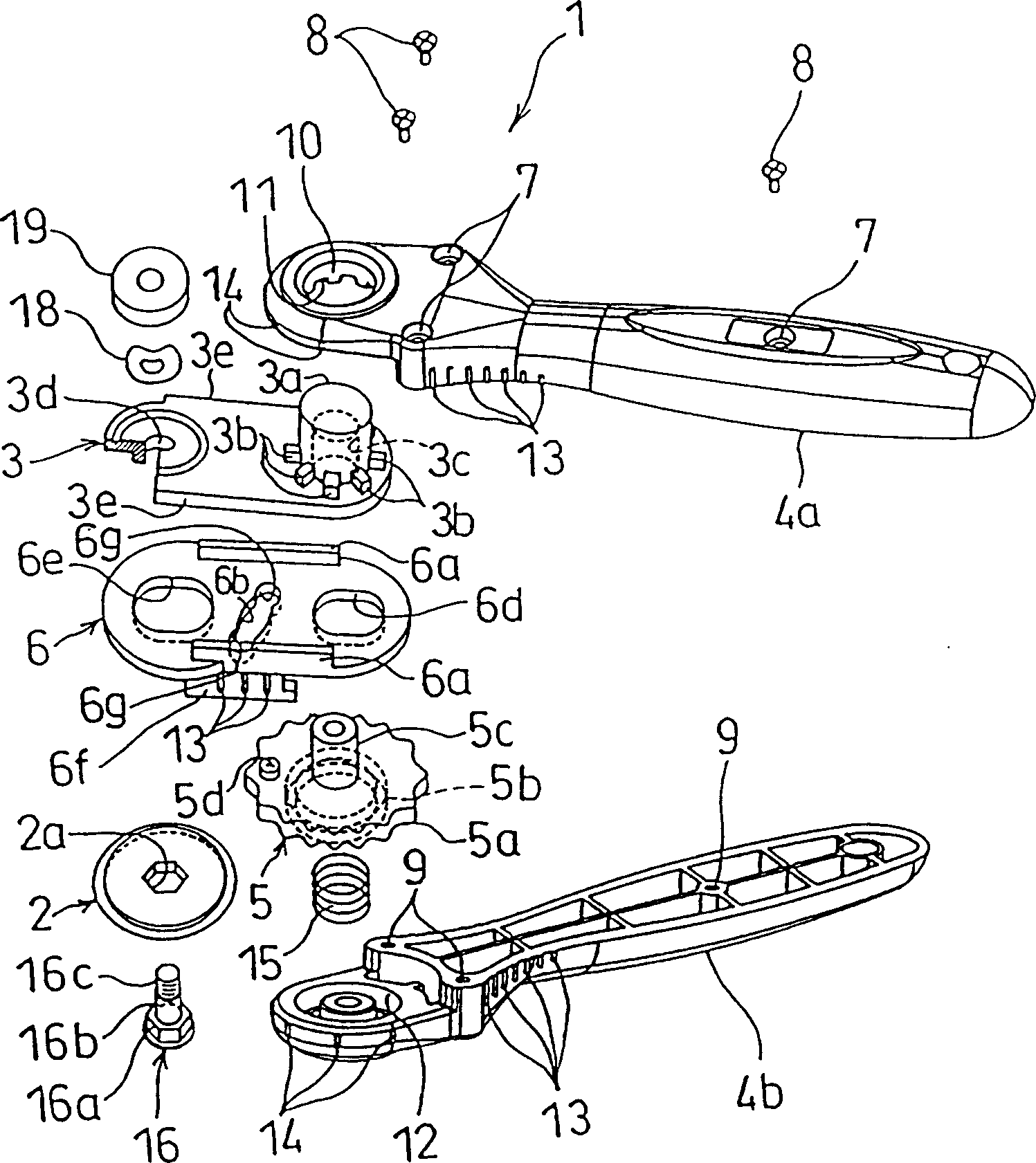

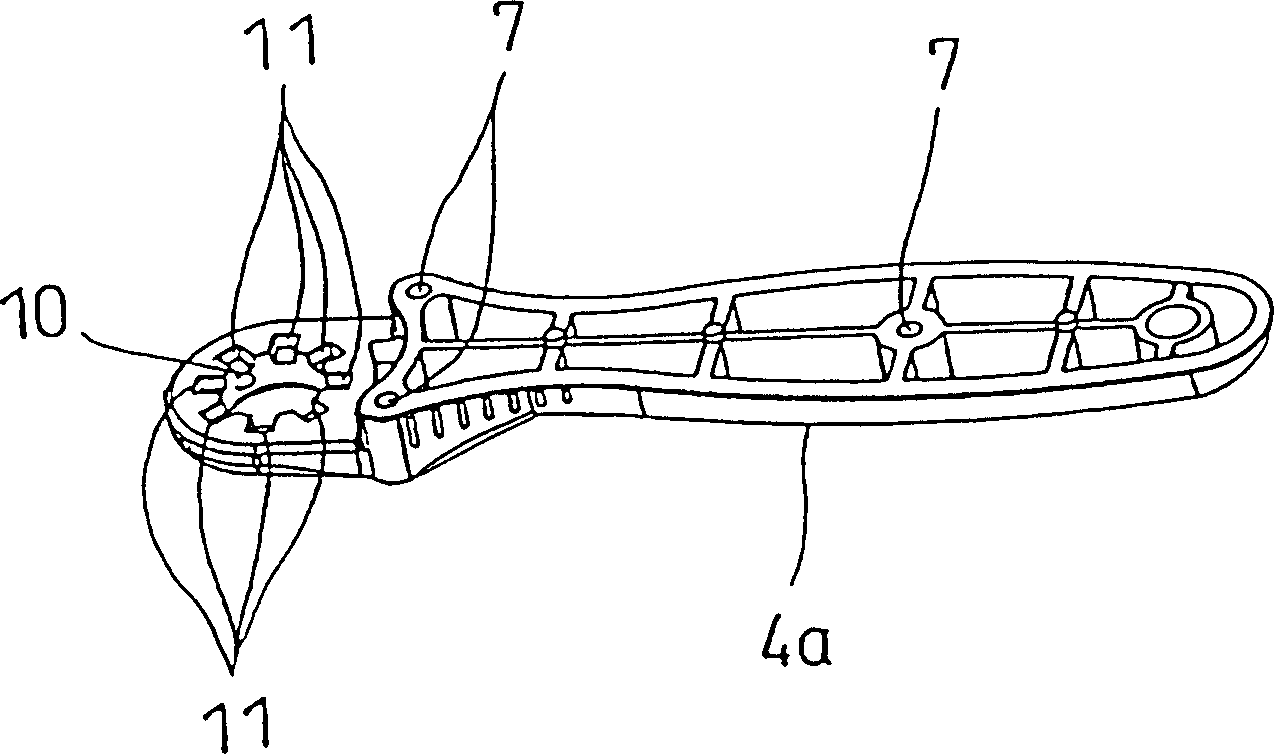

[0028] Next, each constituent part of the tool 1 is explained in detail. like figure 2 As shown, the knife ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap