Heat-resistant composite building material based on epoxy resin

A technology of epoxy resin and epoxy resin glue, applied in the field of building materials, can solve the problems of limited application and development, poor fracture toughness and impact resistance, low upper limit temperature, etc., achieve good thermal stability and mechanical properties, and improve the skeleton Stiffness, effect of increasing bond density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A heat-resistant composite building material based on epoxy resin, including 60 parts of cement and 40 parts of epoxy resin adhesive, and the epoxy resin adhesive includes the following components in weight percentage: the following components in weight percentage: Heat-resistant epoxy resin 80%, curing agent 8%, reactive diluent 12%;

[0040] Described curing agent is diethylenetriamine;

[0041] Described reactive diluent is allyl glycidyl ether;

[0042] The preparation method of described heat-resistant epoxy resin specifically comprises the following steps:

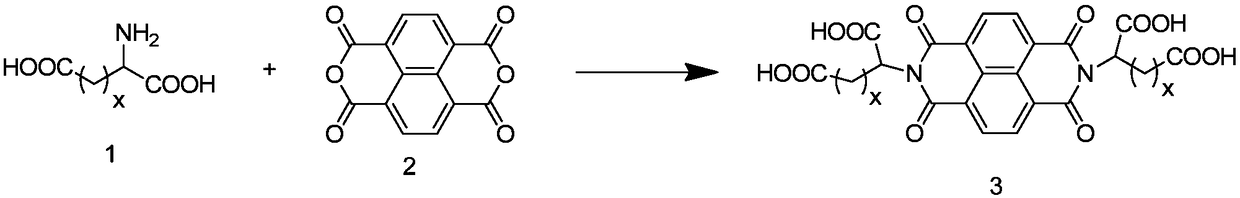

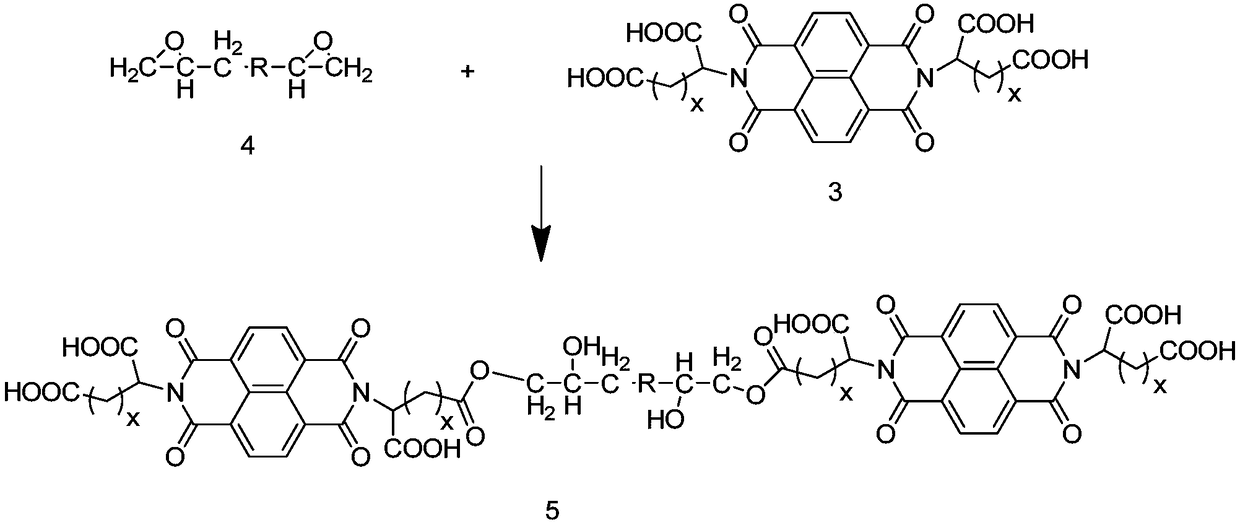

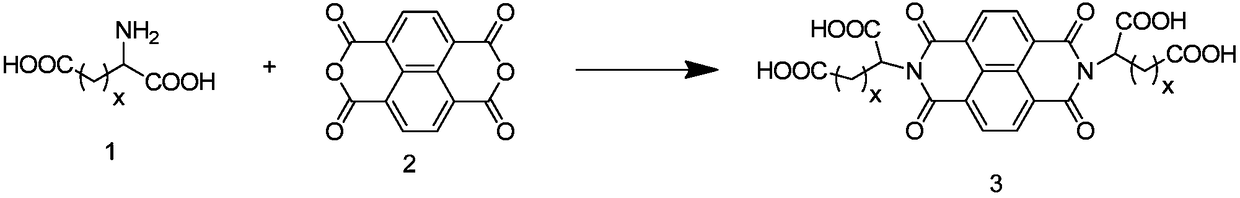

[0043] S1, Synthesis of Naphthalene Tetracarboxyl Amino Acid

[0044] Add 100 mol of amino acid 1 and 220 mol of 1,4,5,8-naphthalene tetracarboxylic anhydride 2 into the reaction flask, heat the oil bath to 130°C at a heating rate of 5°C / min, and conduct condensation reaction for 1 hour. Pour the reactants into hot water, cool and crystallize naturally, and recrystallize the crystals with 30% ethanol aqueou...

Embodiment 2

[0057] A heat-resistant composite building material based on epoxy resin, including 70 parts of cement and 30 parts of epoxy resin adhesive, and the epoxy resin adhesive includes the following components in weight percentage: the following components in weight percentage: Heat-resistant epoxy resin 85%, curing agent 5%, reactive diluent 10%;

[0058] Described curing agent is diethylenetriamine;

[0059] Described reactive diluent is allyl glycidyl ether;

[0060] The preparation method of described heat-resistant epoxy resin specifically comprises the following steps:

[0061] S1, Synthesis of Naphthalene Tetracarboxyl Amino Acid

[0062] Add 100 mol of amino acid 1 and 250 mol of 1,4,5,8-naphthalene tetracarboxylic anhydride 2 into the reaction flask, heat the oil bath to 130°C at a heating rate of 5°C / min, and conduct condensation reaction for 1 hour. Pour the reactants into hot water, cool and crystallize naturally, and recrystallize the crystals with 30% ethanol aqueou...

Embodiment 3

[0074] A heat-resistant composite building material based on epoxy resin, including 66 parts of cement and 34 parts of epoxy resin adhesive, and the epoxy resin adhesive includes the following components in weight percentage: the following components in weight percentage: Heat-resistant epoxy resin 88%, curing agent 6%, reactive diluent 6%;

[0075] Described curing agent is diethylenetriamine;

[0076] Described reactive diluent is allyl glycidyl ether;

[0077] The preparation method of described heat-resistant epoxy resin specifically comprises the following steps:

[0078] S1, Synthesis of Naphthalene Tetracarboxyl Amino Acid

[0079] Add 100 mol of amino acid 1 and 230 mol of 1,4,5,8-naphthalene tetracarboxylic anhydride 2 into the reaction flask, heat the oil bath to 130°C at a heating rate of 5°C / min, and conduct condensation reaction for 1 hour. Pour the reactants into hot water, cool and crystallize naturally, and recrystallize the crystals with 30% ethanol aqueous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com