Link pin type movable floor boards

A raised floor, bayonet-type technology, applied in the field of building decoration materials, can solve the problems of inability to renovate pipelines, inconvenient disassembly, complicated floor manufacturing process, etc., and achieve the effects of flexible use of manufacturing costs, convenient installation and disassembly, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

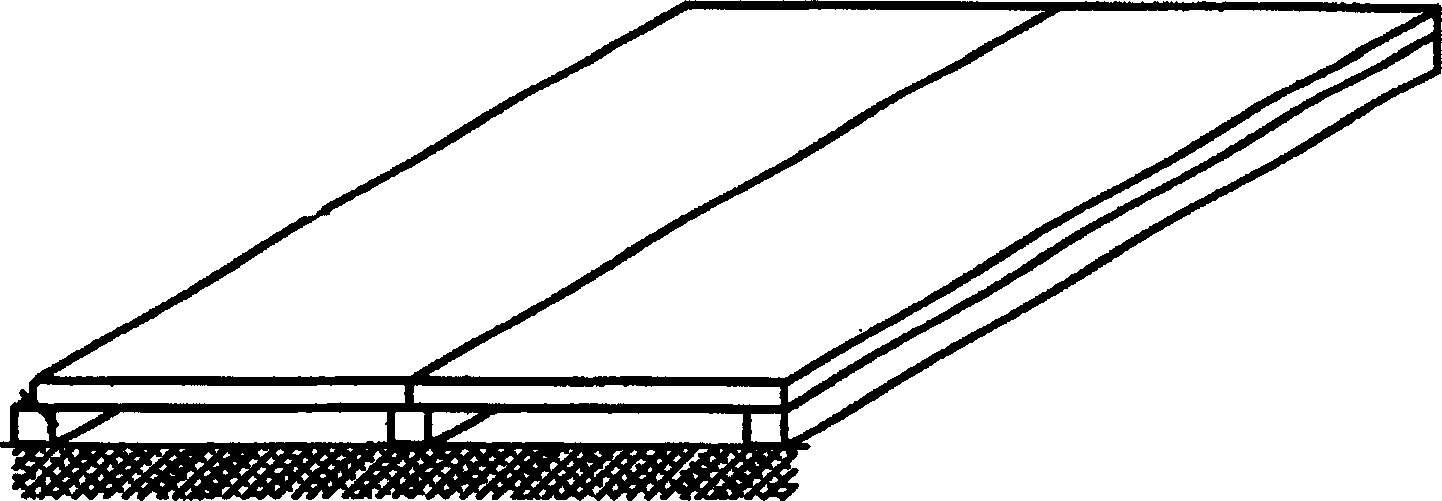

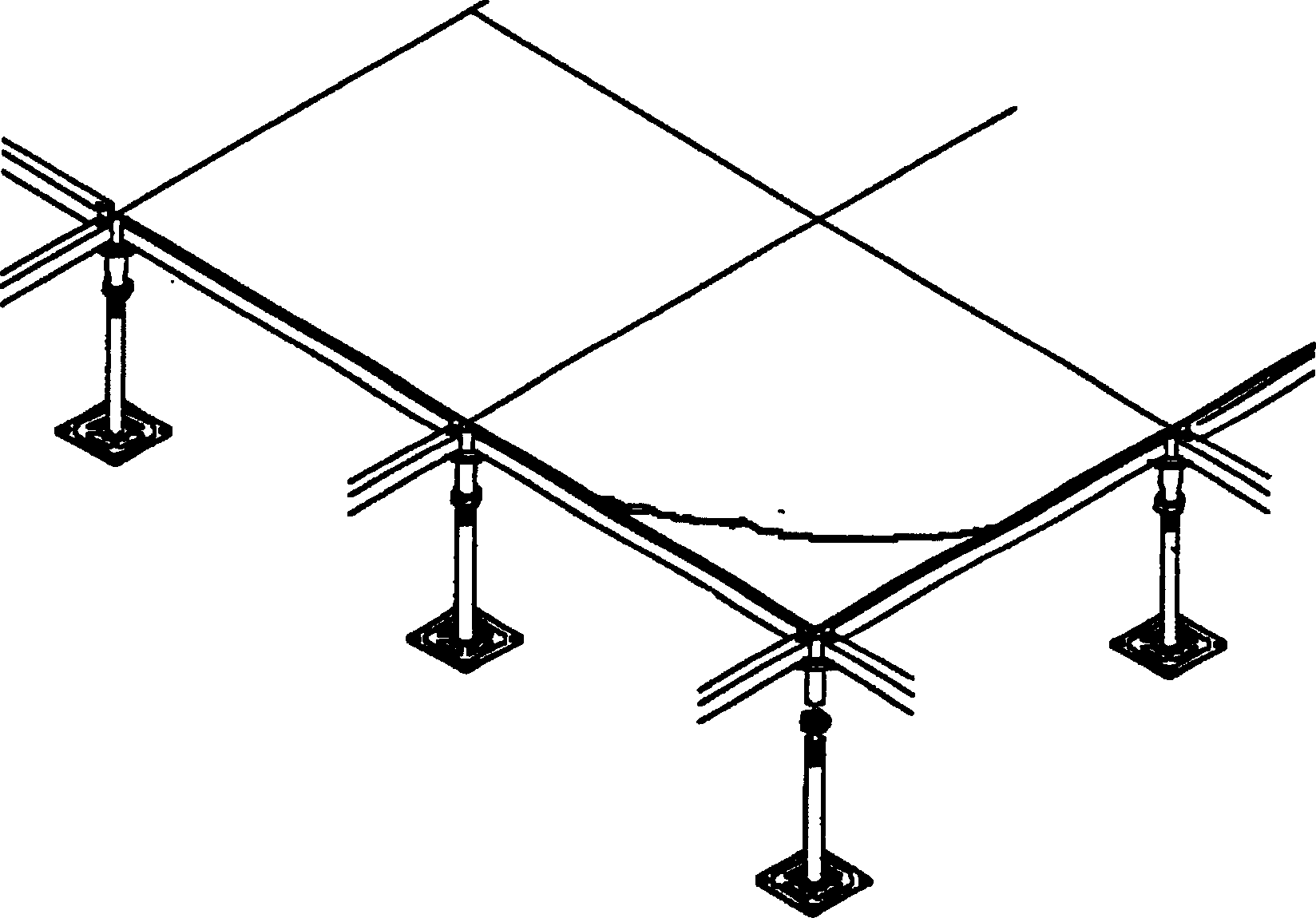

[0033] Embodiment 1: As shown in floor 5-7. 1 is the cross section Shaped tongue-and-groove composite board, one side is a floor groove 11, the other side is a floor beam 12, the beam 2, the support seat 5, and the screw rod 3 fixed in the swing groove 51 arranged on the support seat 5 constitute the floor 1 The supporting device and the setting of the swing groove 51 can play a shockproof and buffering role. The crossbeam 2 is provided with a threaded sleeve 4 threadedly connected with the screw rod 3. The floor 1 is arranged on the crossbeam 2. The formed buffer pad 10 has a bayonet pin 6 fixed under the floor 1, the front part of the bayonet pin 6 is a bayonet head 61, the middle part of the bayonet 6 is a bayonet neck 62, and the radial dimension of the bayonet head 61 is larger than the bayonet pin. The neck 62 is provided with a slot 7 corresponding to the bayonet pin 6 on the crossbeam 2. The bayonet 7 has a bayonet hole 71 slightly larger than the bayonet head 61. Th...

Embodiment 2

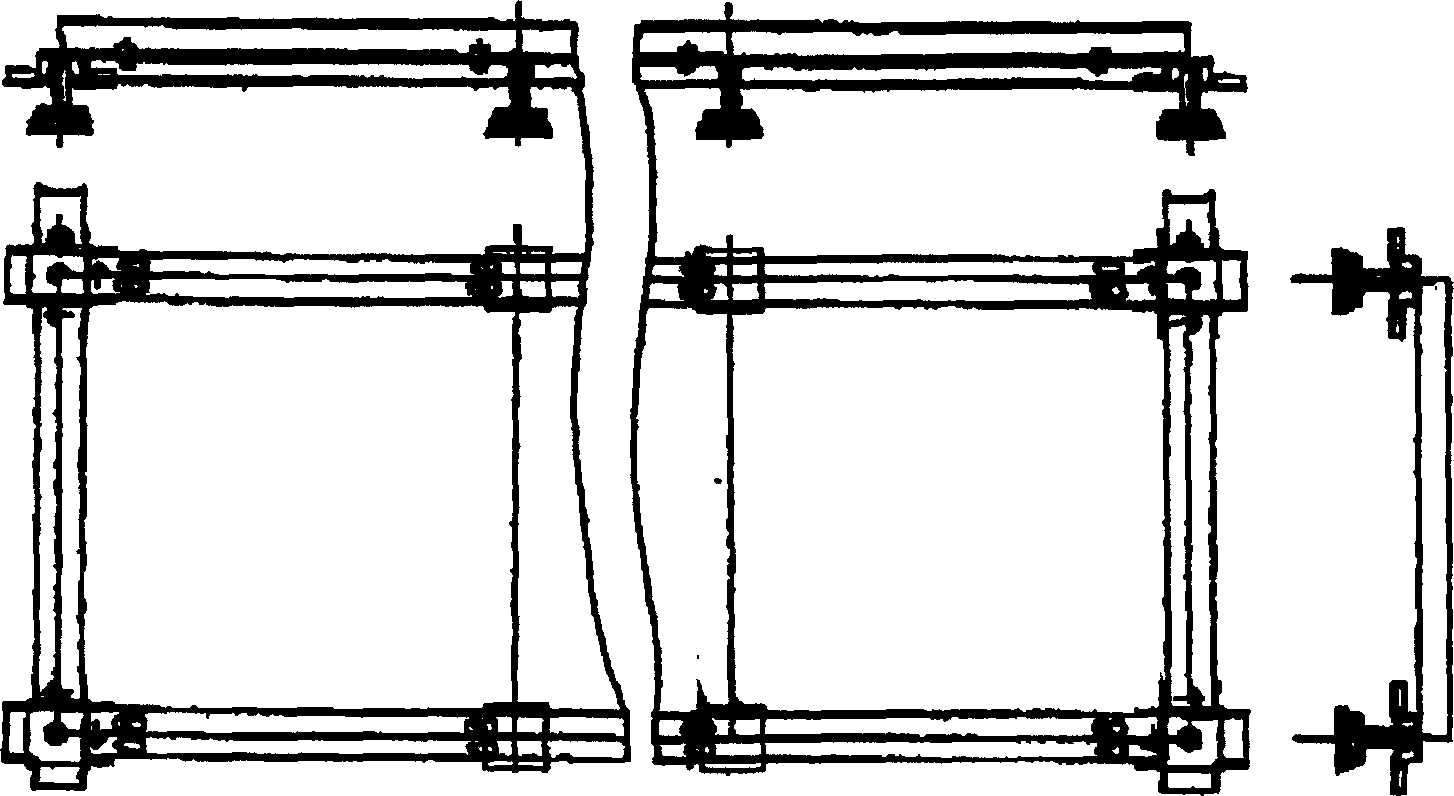

[0035] Embodiment two: if Figure 8 and Figure 9 . The difference from Embodiment 1 is that the floor 1 adopts The composite floor of cross-section; the slot hole is the slot, and the slot 7 of the crossbeam 2 is provided with two relative springs 8 in the shape of "eight" that can hold the pin 6.

[0036] During installation, it is only necessary to align the bayonet pin 6 of the floor 1 with the bayonet groove 7, and press down with a little force, and the bayonet pin 6 is promptly blocked by the spring leaf 8.

Embodiment 3

[0037] Embodiment three: as Figure 10 and Figure 11 . The difference with Embodiment 2 is that the floor 1 adopts Composite floor with shaped cross-section; two spring seats 9 with springs 91 are oppositely arranged below the draw-in groove 7 of the beam 2, and a steel ball 92 is connected to the front ends of the springs 91 of the two opposite spring seats 9, and a steel ball 92 is connected to the opposite two steel balls. The ball 92 can block the bayonet 6 inserted into the bay 7 according to the spring.

[0038] Similar to the installation of Embodiment 2, just align the bayonet pin with the bayonet groove and press down, the bayonet pin is locked by the two opposite steel balls, and the floor and the beam are fitted together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com