Rapidly connecting electromagnetic relay with protruding arm movable spring extended sheet for limitation

A technology of electromagnetic relay and lead-out piece, which is applied in the direction of electromagnetic relay, electromagnetic relay details, relay, etc., and can solve the problems of unable to meet the use requirements, high output isolation, and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

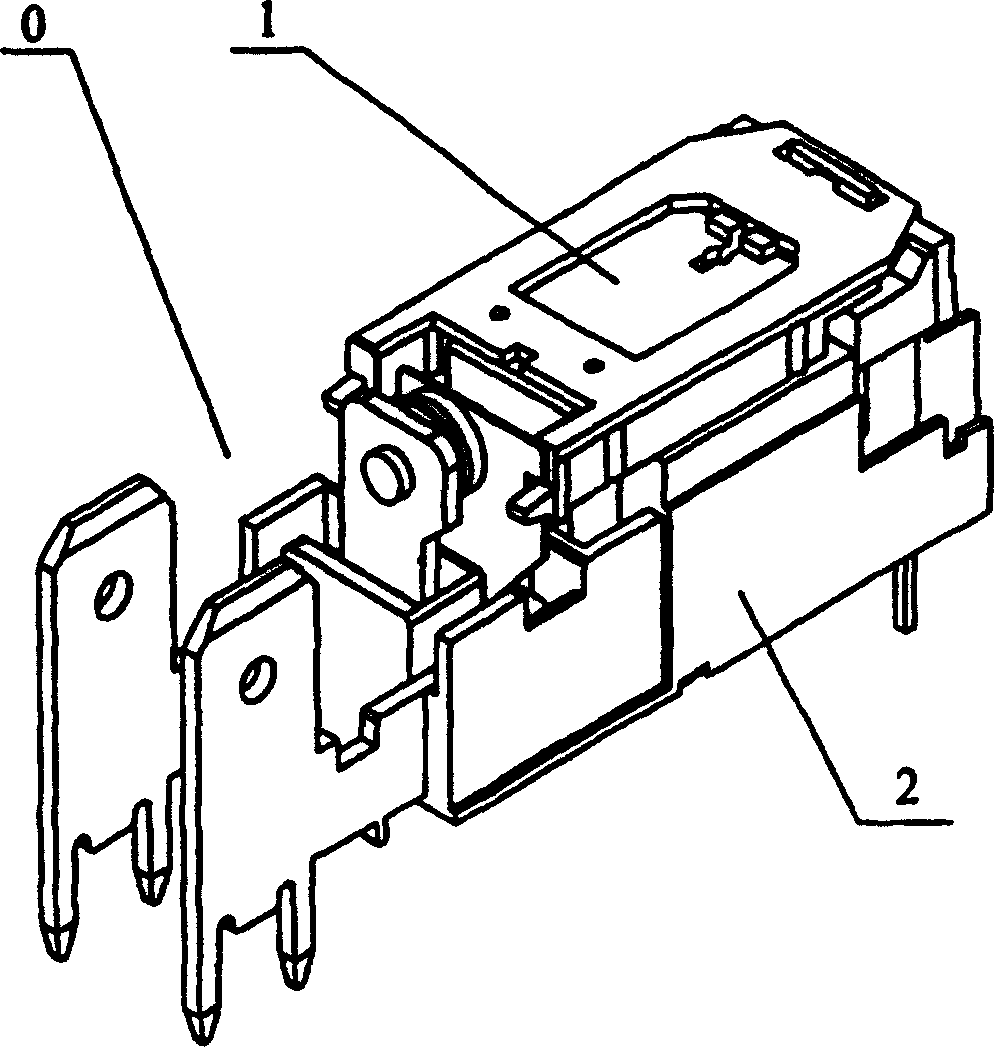

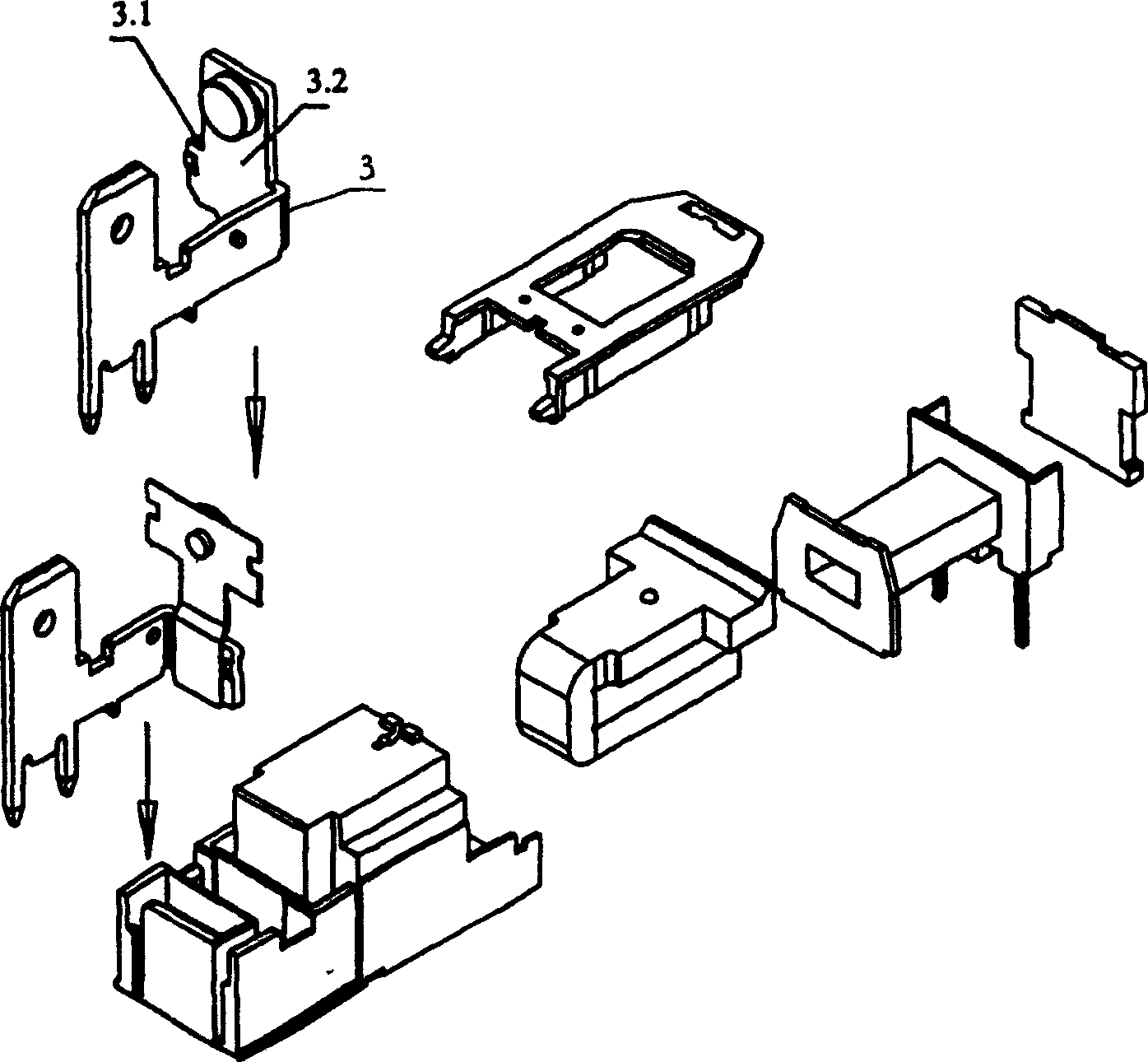

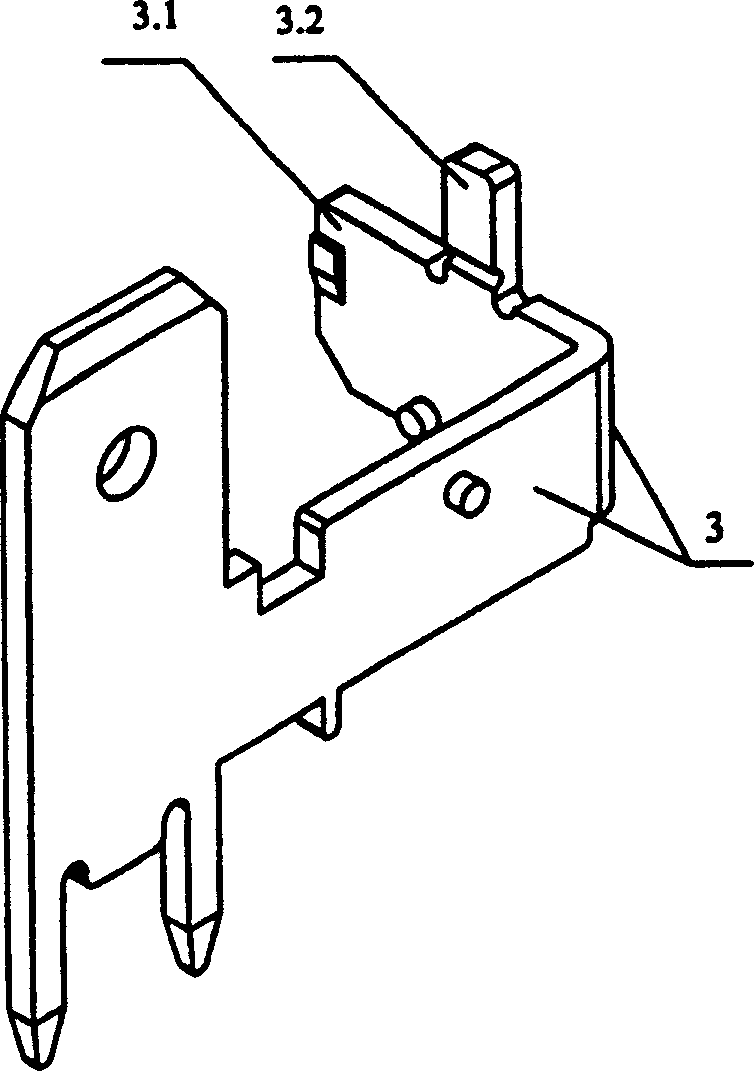

[0016] Such as figure 1 , 2, the present invention includes a magnetic circuit system 0, a contact system 1 and a base 2. see image 3 , 4. On one side 3.1 of the L-shaped moving spring lead-out piece 3 of the normally open contact structure of the contact system, there is a limit protrusion arm 3.2, which is used to limit the rebound position of the moving reed to ensure that the push block and There is a certain gap between the moving reeds 4 to reduce the initial driving voltage of the electromagnetic relay and achieve the purpose of quick connection.

[0017] On the base, an L groove 5.1 (see Figure 5 ).

[0018] The static spring 6 of the contact system is also designed in an L shape, and one side 6.1 is matched and clamped with the L groove 5.2 of the base (see Image 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com