Natural ventilating and mechanical ventilating dual-purpose system for continuous-building type greenhouse

A technology of natural ventilation and mechanical ventilation, applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of difficult to ensure sealing, high operating cost, large opening of windows, etc., to achieve both ventilation performance and economical efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

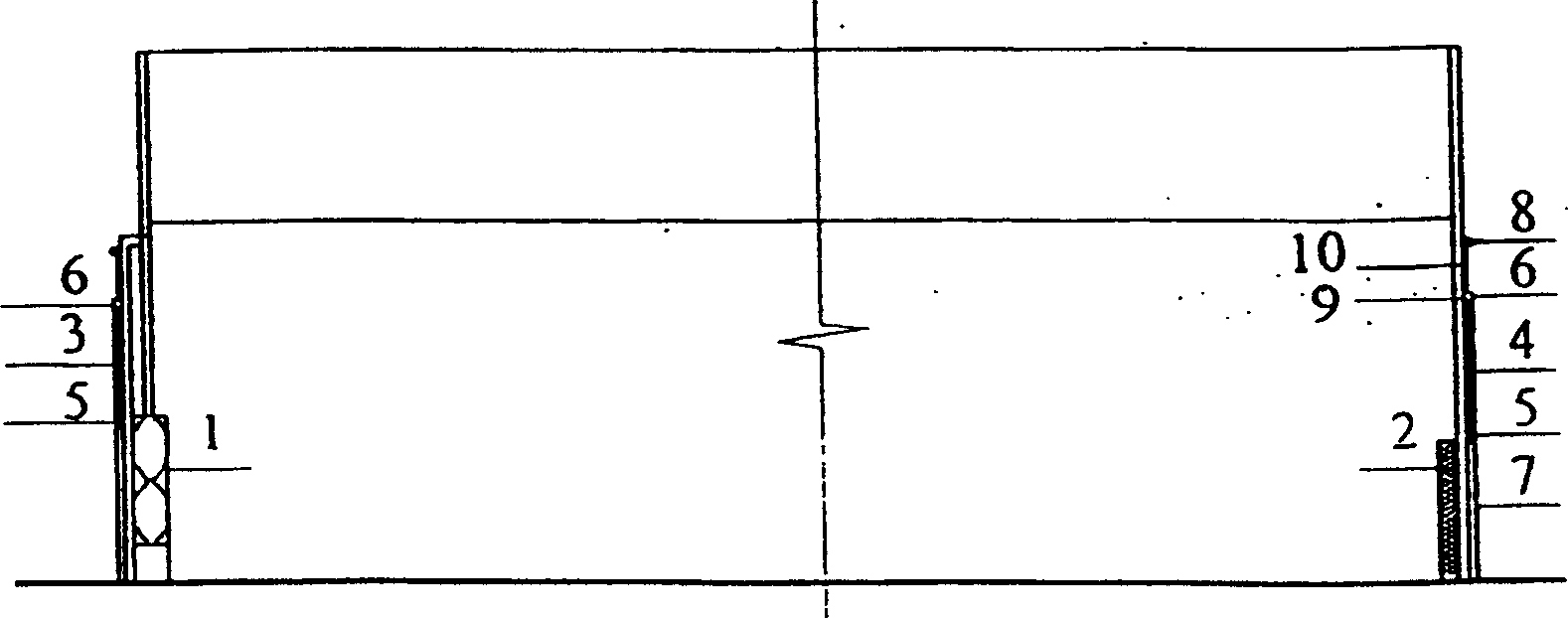

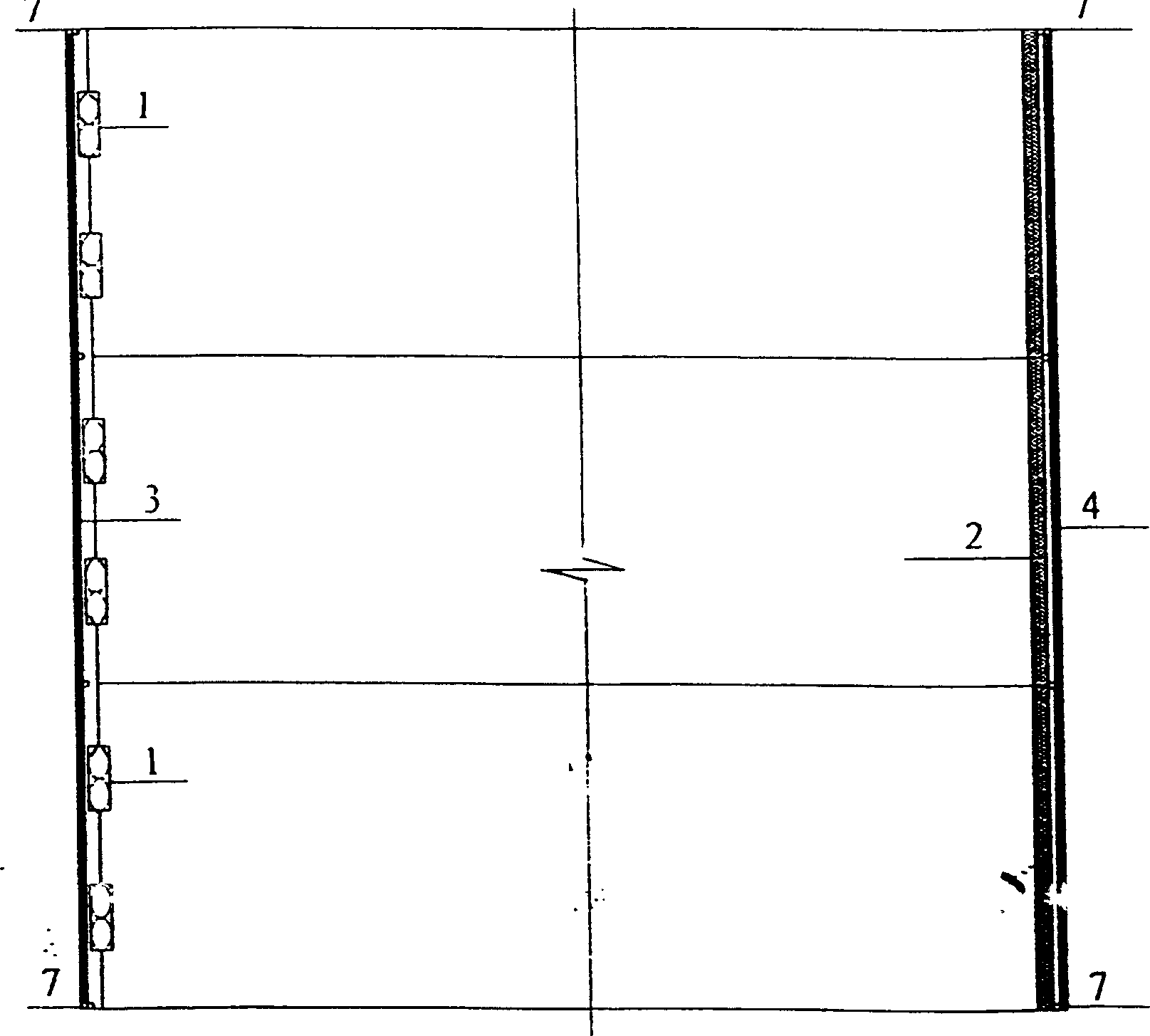

[0020] Such as figure 1 , figure 2 As shown, it includes: fan 1, wet curtain 2, natural ventilation window 3 on the side of the fan, natural ventilation window 4 on the side of the wet curtain, sliding window mechanism of the natural ventilation window, and sealing device of the natural ventilation window. Several fans 1 are installed at the bottom of one end or side of the greenhouse, natural ventilation windows 3 on the fan side are installed on the upper guide rail fixing rod 7 of the fan 1, and wet curtains 2 are installed at the other corresponding end or side bottom of the greenhouse The natural ventilation window 4 on the side of the wet curtain is installed on the guide rail fixing rod 7 on the top of the wet curtain 2; the natural ventilation window 3 on the fan side and the natural ventilation window 4 on the wet curtain side are respectively equipped with a sliding window mechanism and Sealing means.

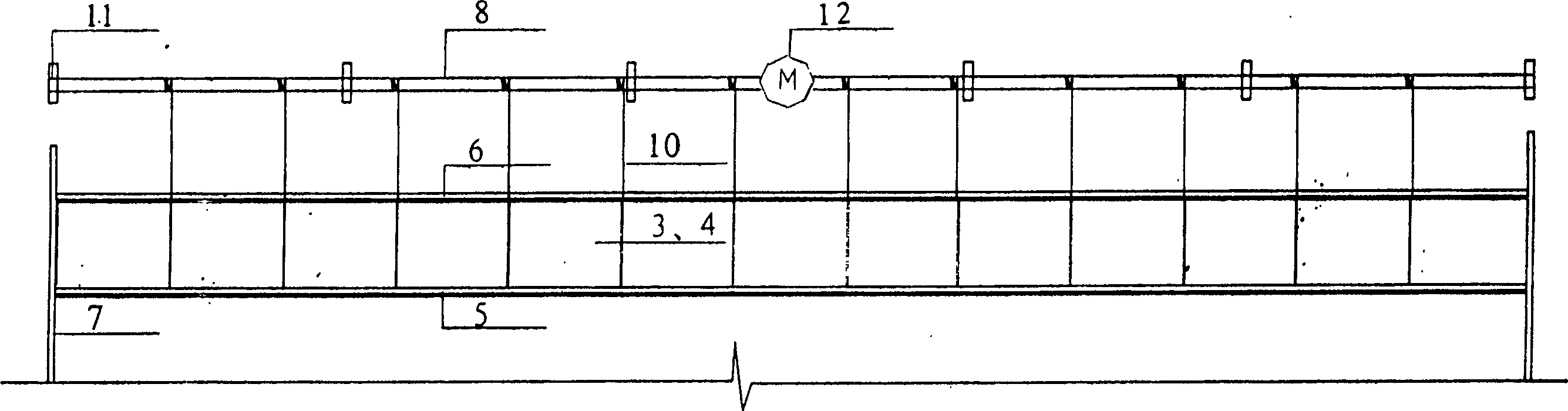

[0021] Such as figure 1 , image 3 As shown, the sliding wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com