Double guide mechanism

A guide rail and duplex technology, applied to furniture parts, household appliances, drawers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, a more detailed description will be given based on the embodiment examples shown in the accompanying drawings of the present invention.

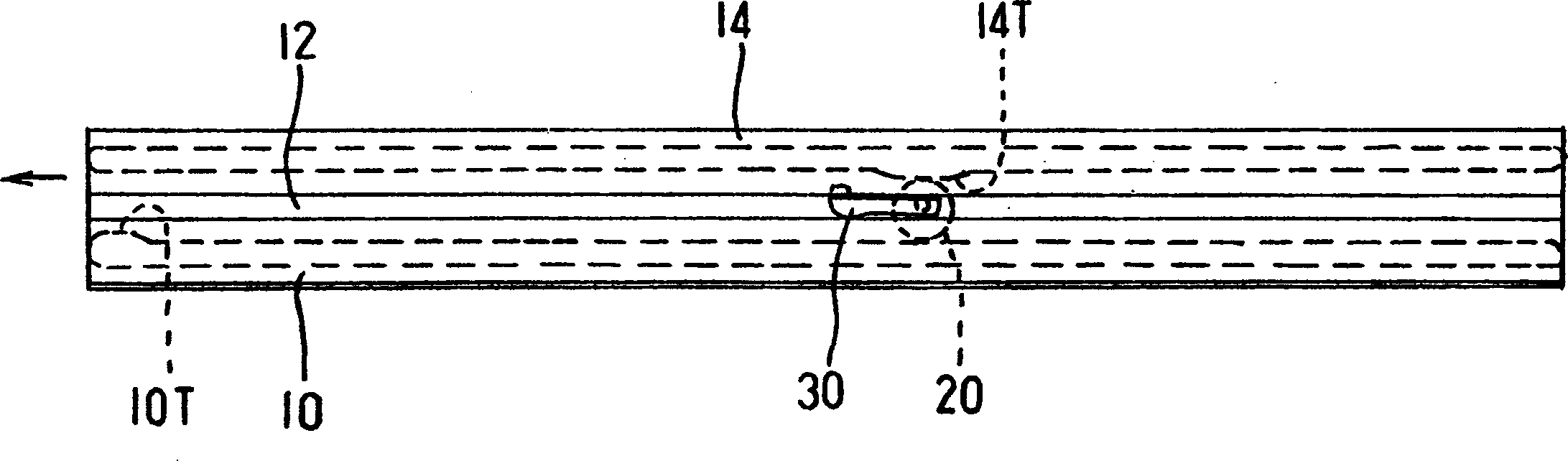

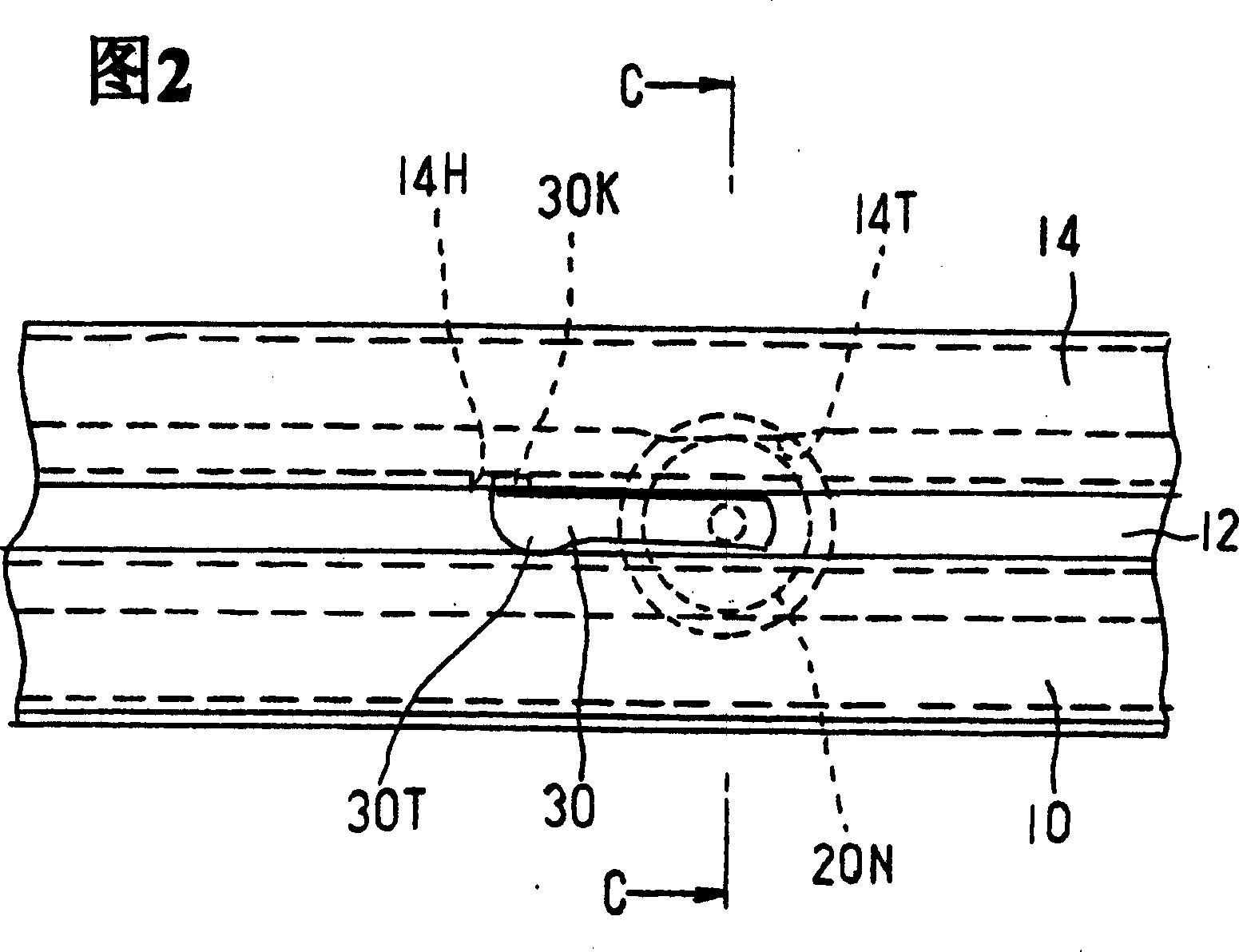

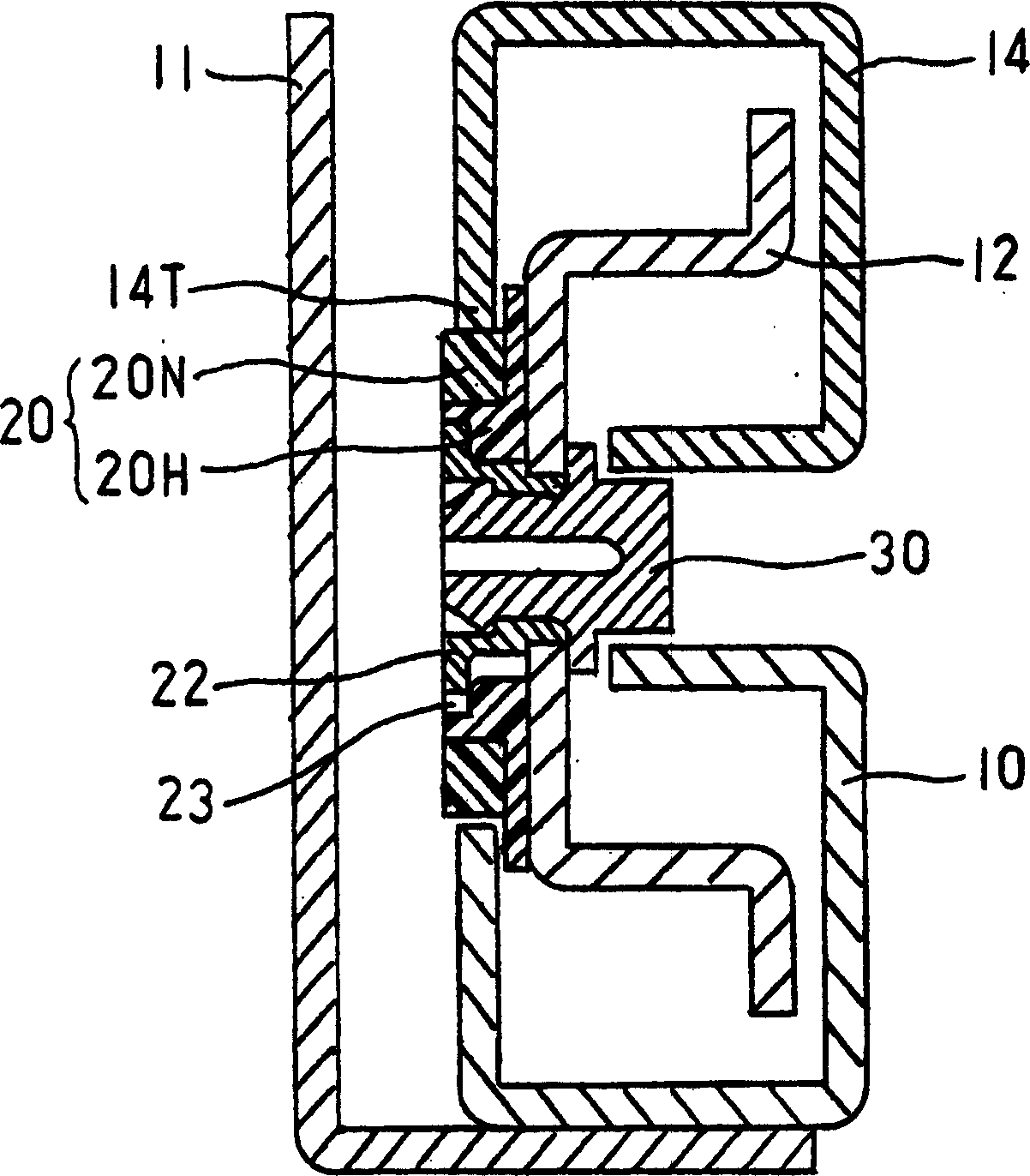

[0026] figure 1 It is a side view of the guide rail mechanism of the unillustrated cabinet drawer with the compound guide rail mechanism related to the present invention in the storage state, and Fig. 2 is an enlarged view of its main parts, image 3 It is an enlarged cross-sectional view according to the arrow line C-C in FIG. 2 . In the cross-section, on one end side (lower side) of the middle rail 12, a frame side rail 10 is provided. The rail is rectangular and surrounds the above-mentioned one end. One corner is open. It is provided by (a combination of) a plurality of rollers (combination) that are not shown in the figure and are provided in the front-rear direction as rotating bodies. In addition, the other end side (upper side) is provided with a drawer side rail 14, which is rectangular and surrounds the above-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap