Method of lowering residual fluorind in sedimentation reaction chamber cavity body

A deposition reaction and chamber technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of reducing process stability, process pollution, dropping on the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above and other purposes, features, and advantages of the present invention more clearly understood, the preferred embodiments are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

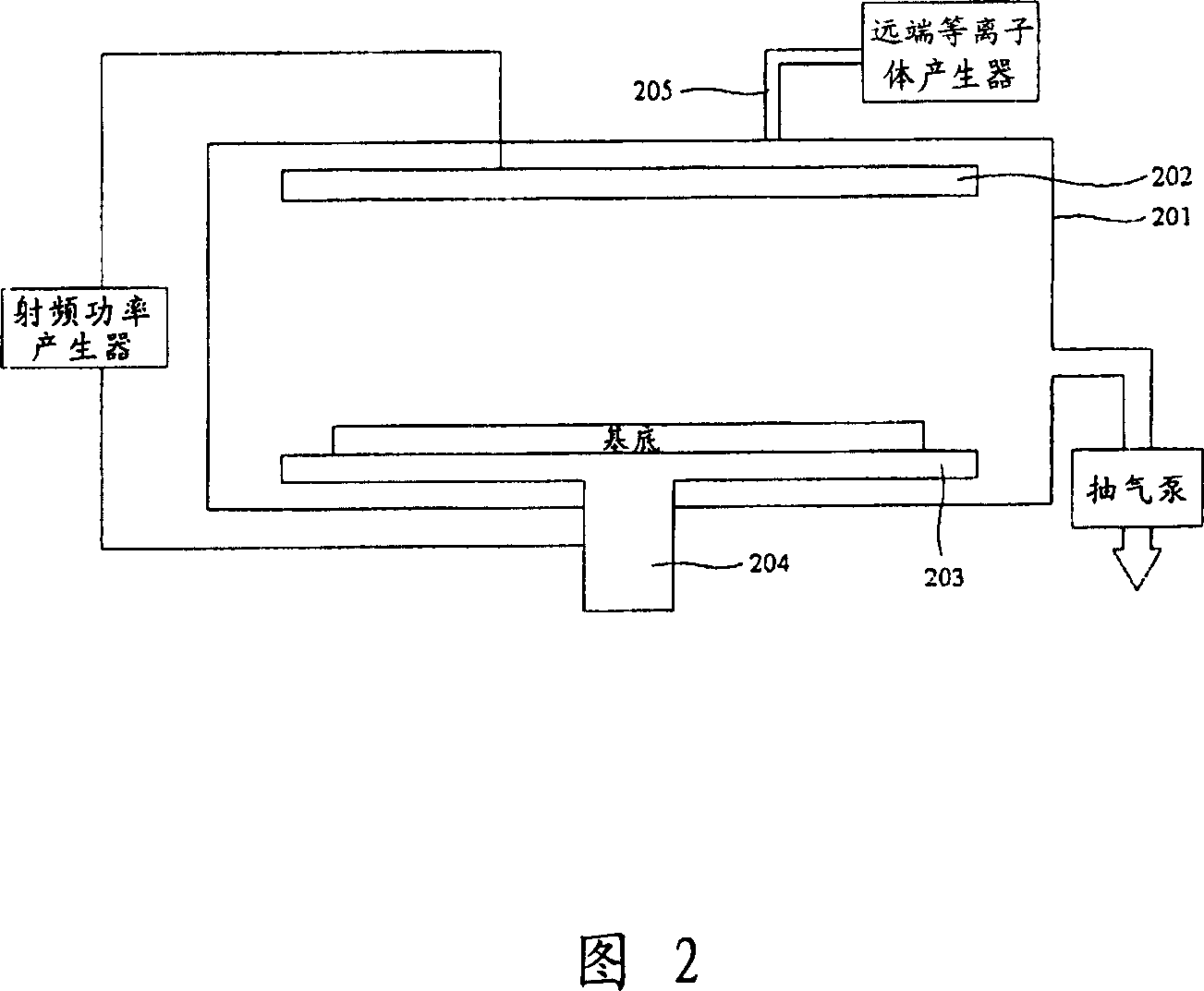

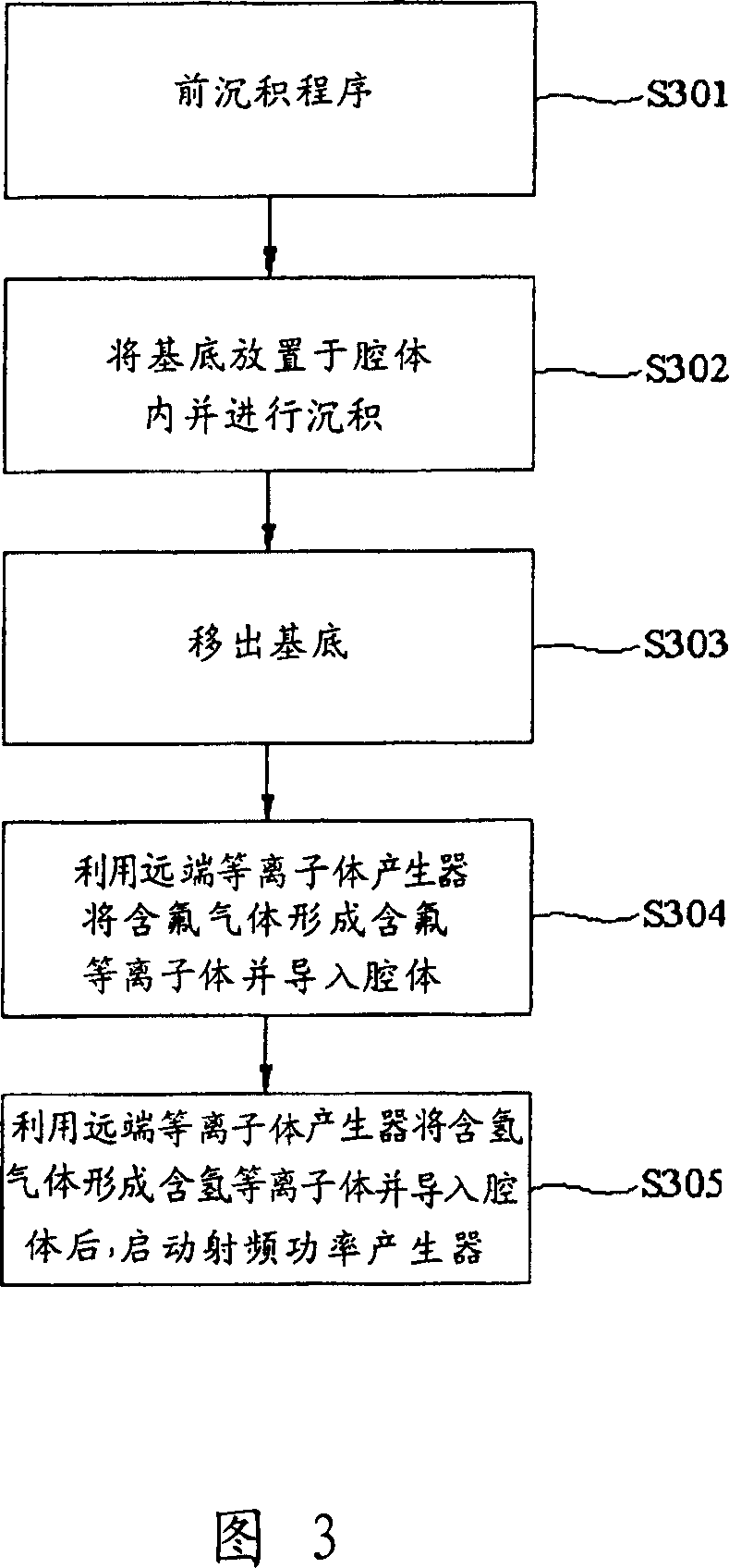

[0028] Please refer to FIG. 2 and FIG. 3 at the same time. FIG. 2 shows the deposition reaction device of the present invention; FIG. 3 is a flow chart showing the method for reducing fluorine residue in the deposition reaction chamber cavity provided by the present invention.

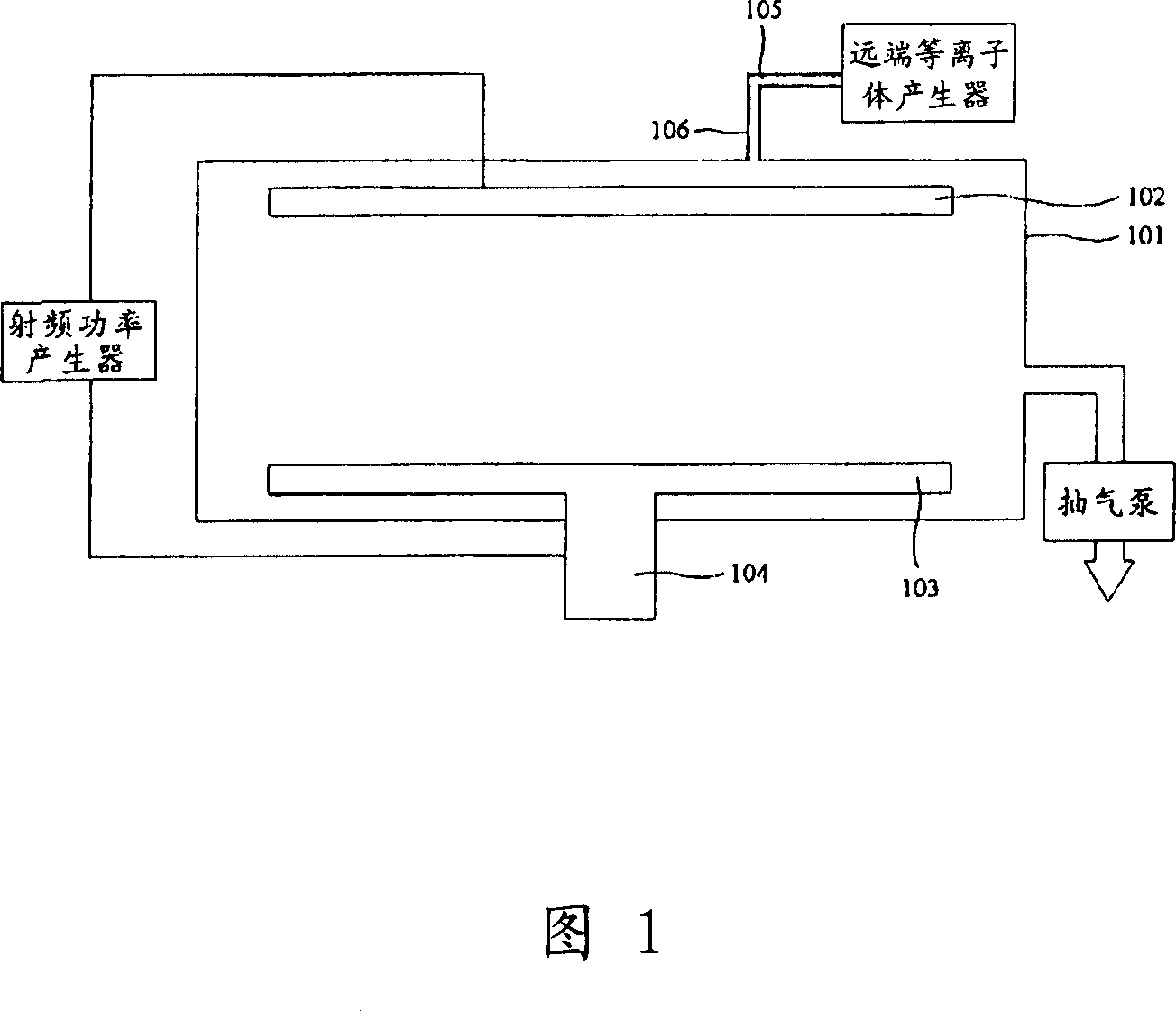

[0029] The deposition reaction device includes a deposition reaction chamber cavity 201, a radio frequency (RF) power generator, a remote plasma generator, and an air pump. The chamber body 201 of the deposition reaction chamber has an upper electrode 202 , a lower electrode 203 , and a support frame 204 , and the lower electrode 203 is placed on the support frame 204 . The upper electrode 202 and the lower electrode 203 are controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com