Cylinder lock body

A lock body, cylindrical technology is applied in the field of cylinder lock bodies, which can solve the problems of increasing the strength and fracture of the cylinder lock body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

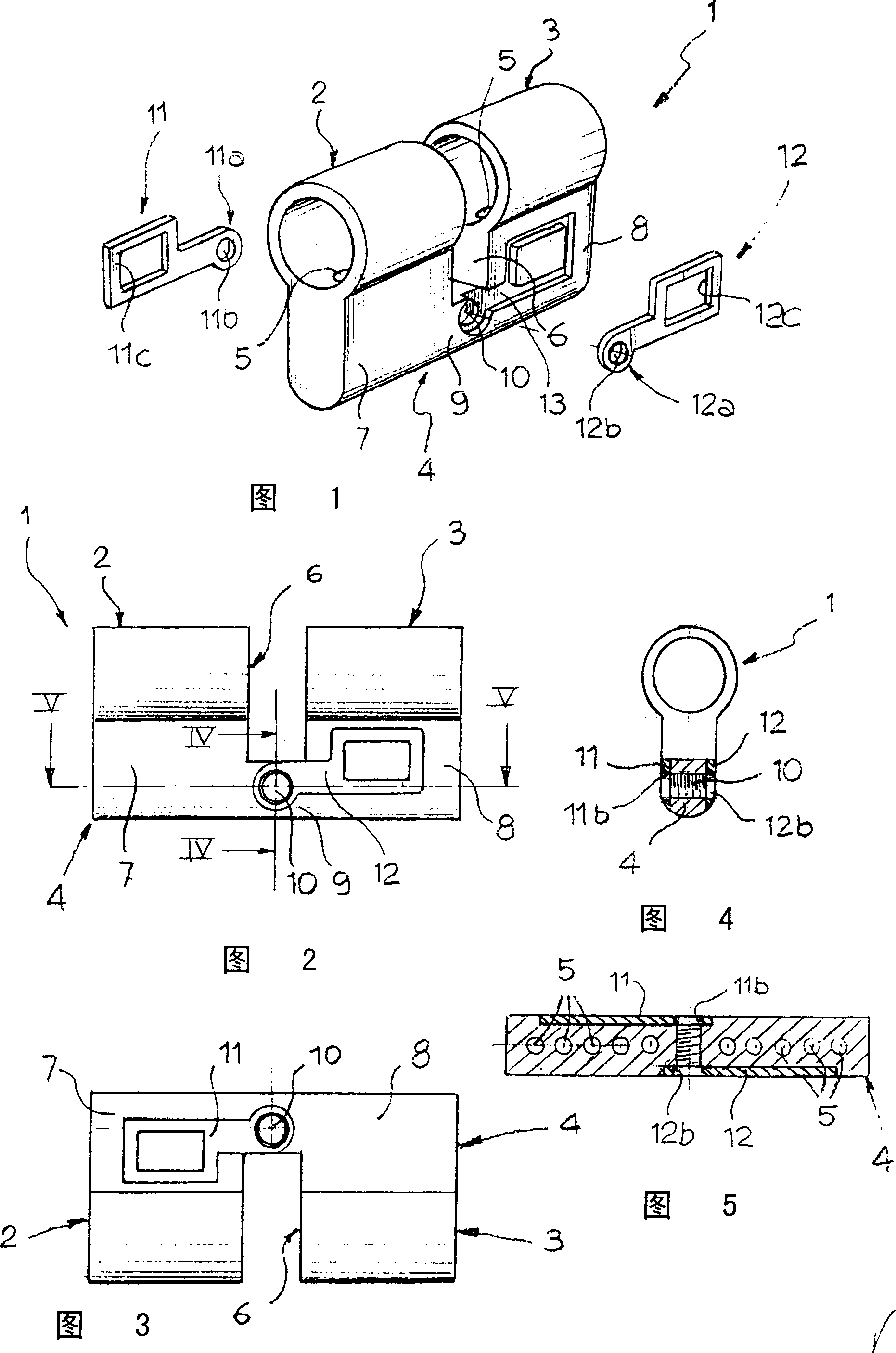

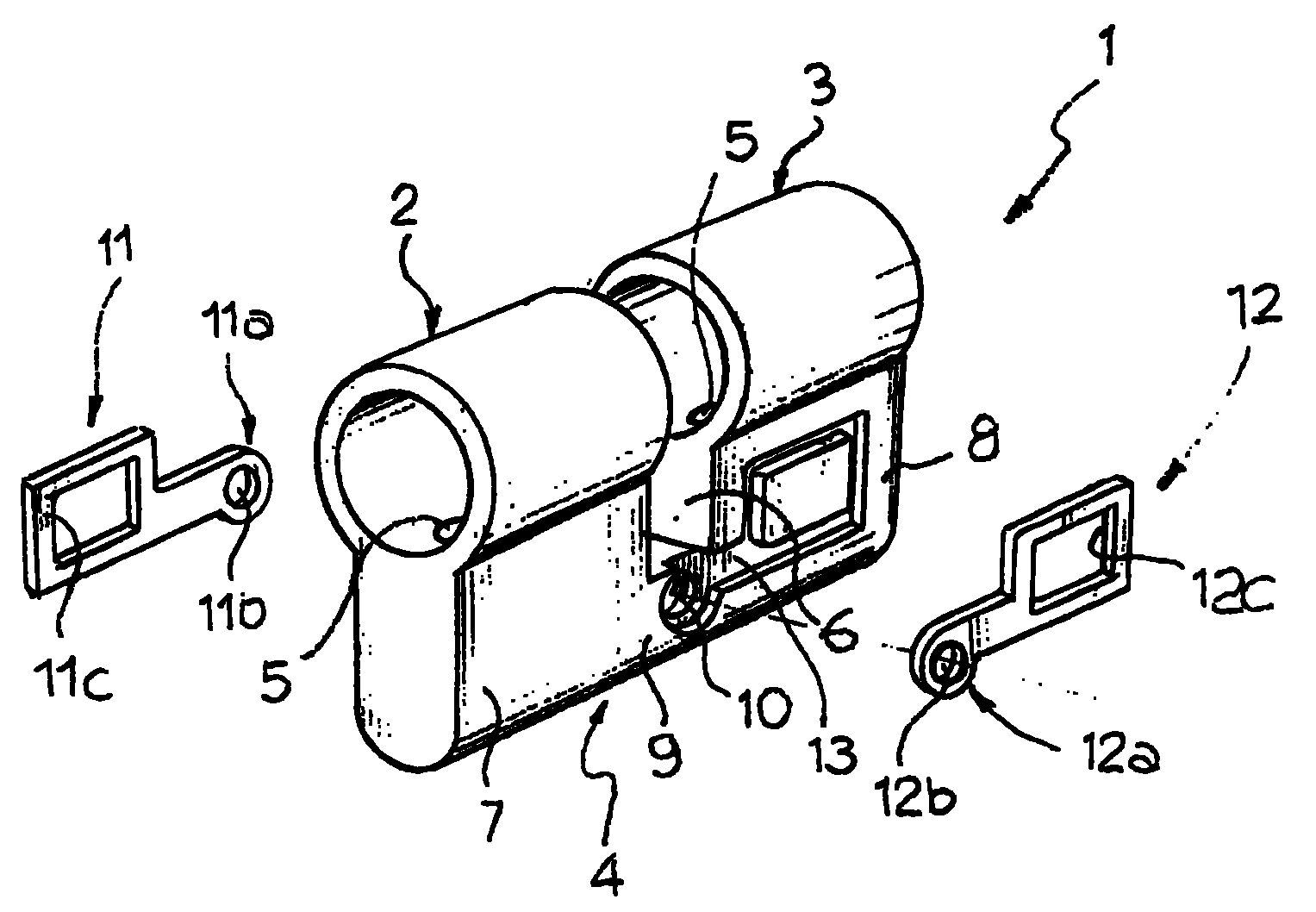

[0011] Referring to the drawings, it can be seen that the cylindrical lock body 1 has two opposite and coaxial cylindrical half-shells 2, 3 ready to receive a cylindrical lock cylinder (not shown). A flange 4 protrudes from one side of the cylindrical half-shells 2, 3, in which some small holes 5 are formed to receive cylinder lock tumblers (also not shown) according to known techniques, these small holes Holes are made in the inner cavities of the cylindrical half-shells 2,3.

[0012] The two half-shells 2, 3 are separated from each other by a notch 6 intended to be occupied by a rotatable pawl (not shown) of the lock, which notch also extends through a part of the flange 4, forming the two half-shells. Flanges 7, 8, which are connected together by a bridge 9.

[0013] The above shapes are familiar and conventional in the art. Also according to the prior art, there is also a threaded through-hole 10 on the bridge 9 for engaging a screw (not shown) to secure the lock body to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com