Differential pressure transmitter

A technology of differential pressure transmitter and pressure sensor, which is applied in instruments, measuring fluid pressure, and measuring fluid pressure through mechanical components, etc., which can solve the problems of affecting the measurement accuracy and the easy deformation of the isolation diaphragm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

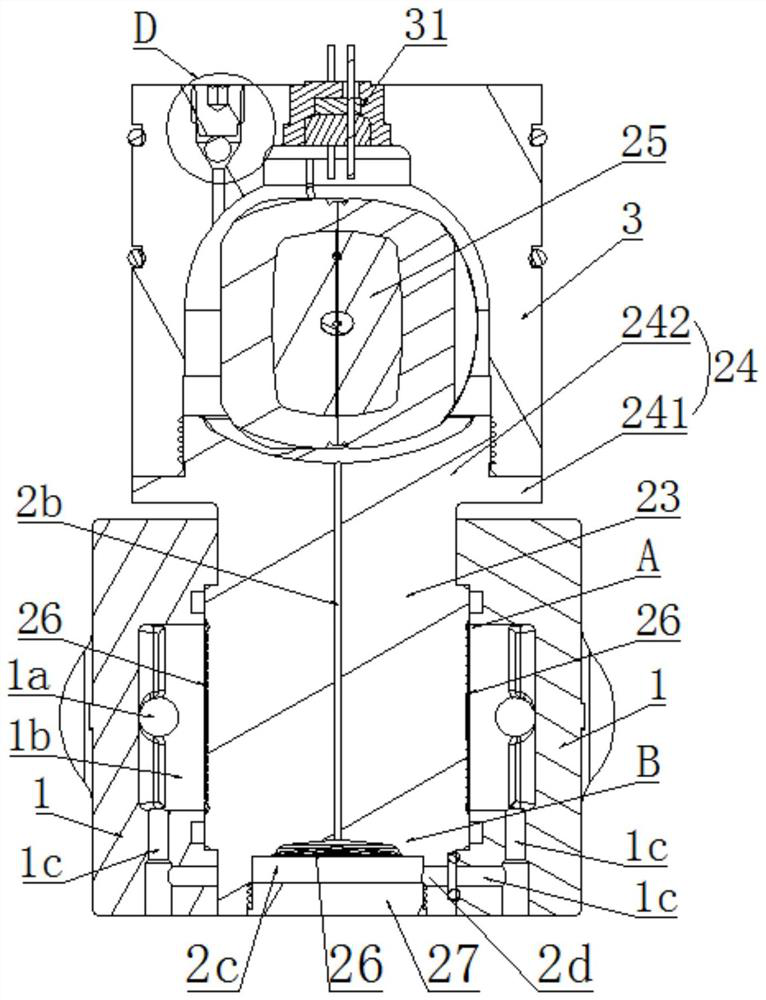

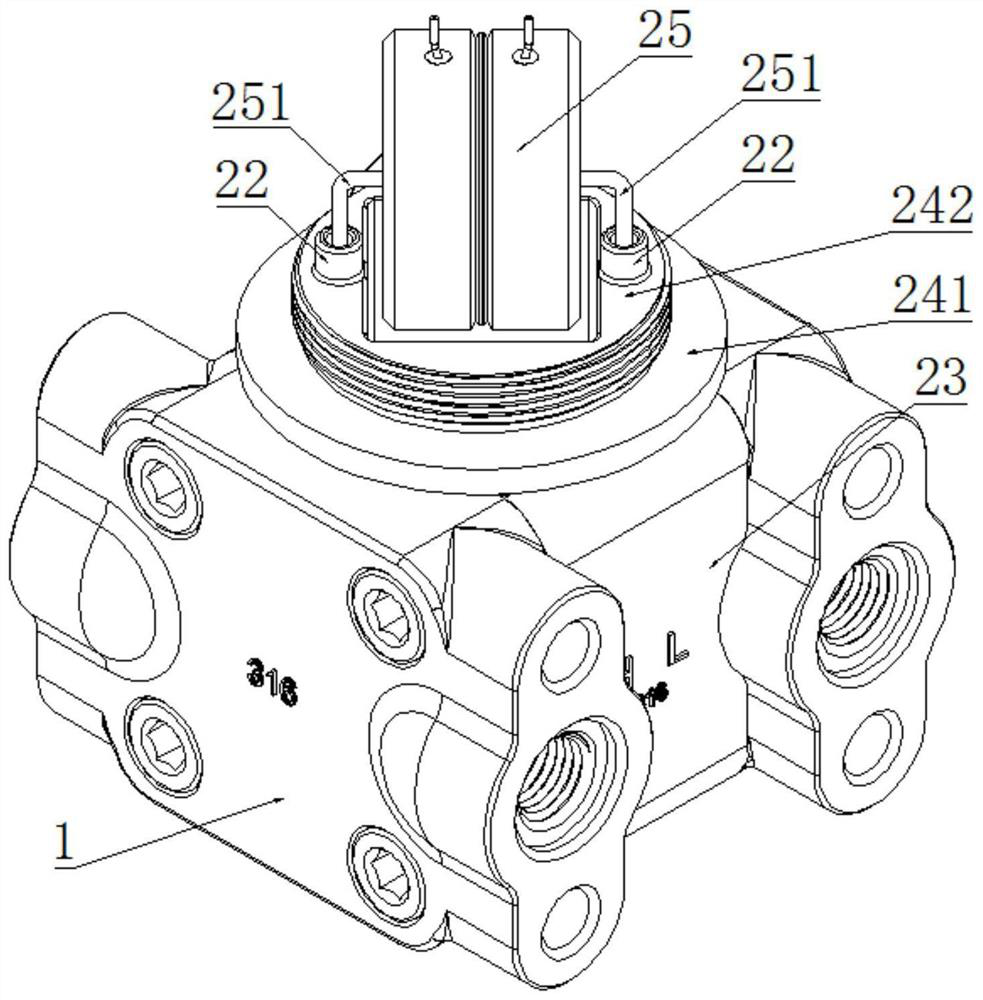

[0046] like Figure 1 to Figure 11As shown, a differential pressure transmitter includes a pressure introduction seat 2 and a sealing cover 3, the sealing cover 3 is set on the pressure introduction seat 2, and a diaphragm type pressure sensor is arranged inside the sealing cover 3. The sensor 25 is provided with a lead wire opening on the top of the sealing cover 3, and the diaphragm pressure sensor 25 is connected with a signal lead wire, and the signal lead wire passes through the lead wire opening outward, and a lead wire is wrapped on the signal lead wire Connector 31, the lead wire connector 31 is blocked in the lead wire opening and sealed with it;

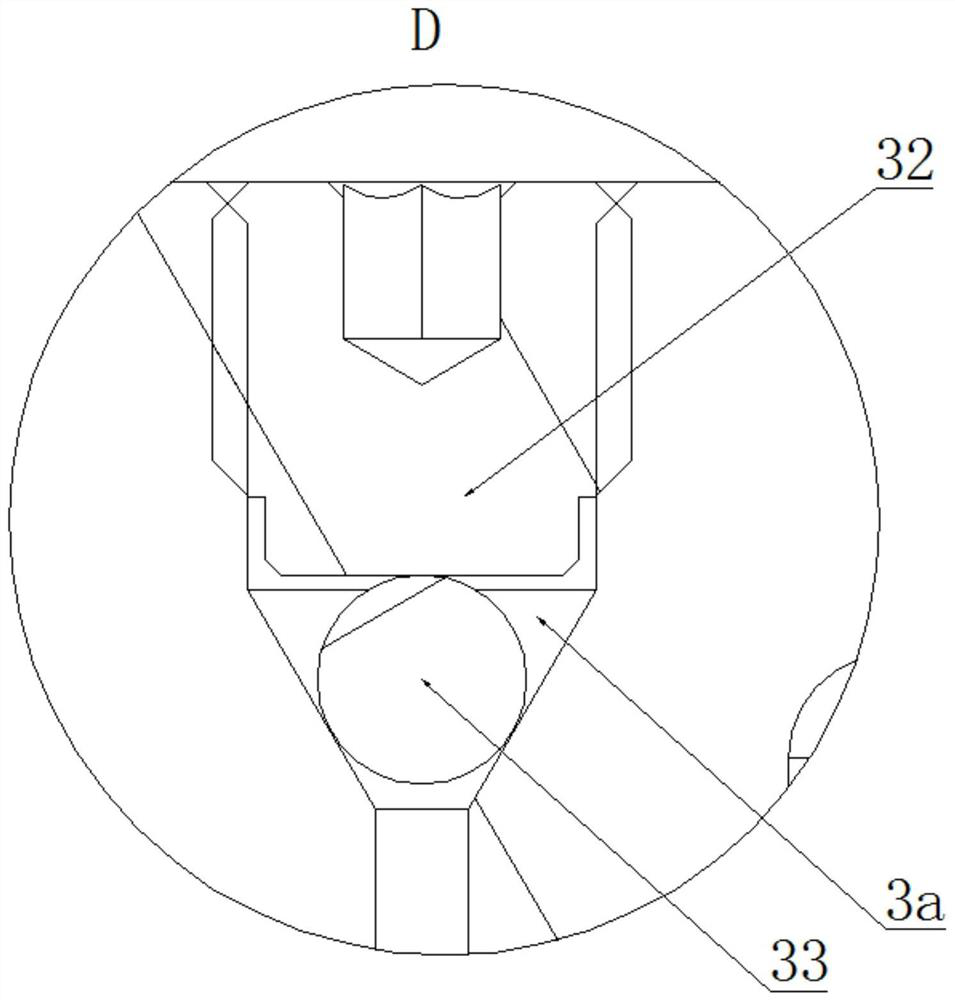

[0047] Also be provided with negative pressure oil injection hole 3a on described sealing cover 3, be provided with oil plug 32 in this negative pressure oil injection hole 3a.

[0048] in:

[0049] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com