Water plugging agent and preparation method thereof

A technology of water blocking agent and phase inversion agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problem of water blocking agent glue forming difficulty, low gel blocking strength, weak gel adsorption, etc. problems, to achieve the effect of increasing the difficulty of construction, improving rigidity, and improving adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

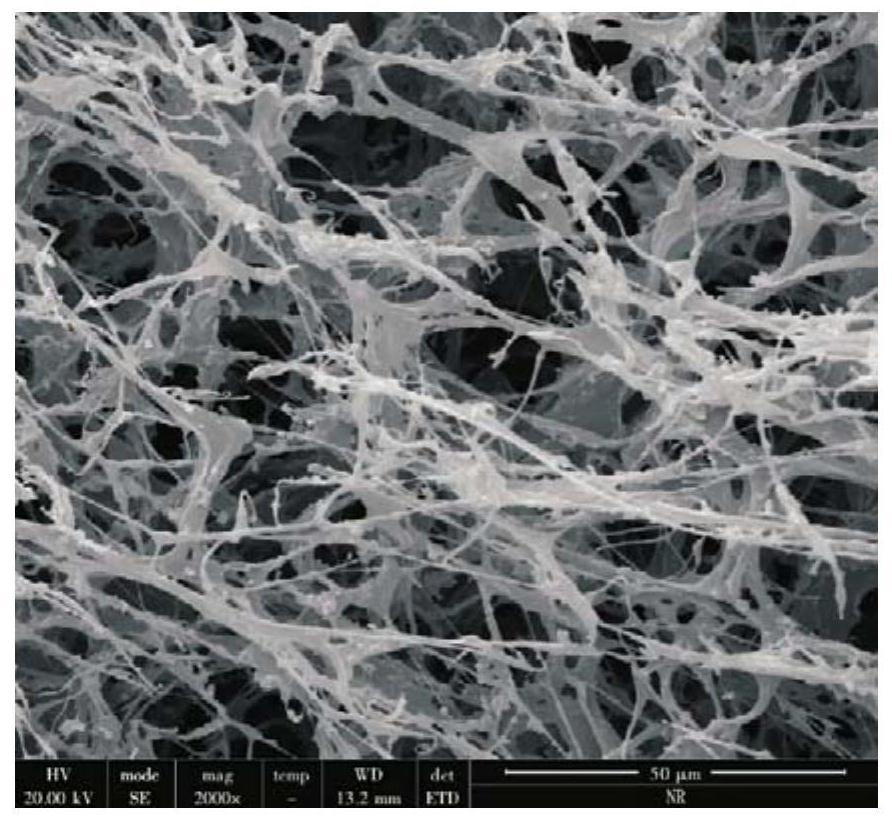

Image

Examples

preparation example Construction

[0038] The present invention provides the preparation method of the water shutoff agent described in the first aspect of the present invention in the second aspect, the method comprises the following steps:

[0039] (a) uniformly mixing acrylamide, strength monomer, high adhesion promoting monomer, micro-crosslinking agent, associative thickener, responsive monomer, associative monomer and water to obtain an aqueous phase solution;

[0040] (b) mixing the oily solvent, emulsifier, co-emulsifier and polymerization stabilizer uniformly to obtain an oil phase solution;

[0041] (c) adding the water phase solution, azo initiator and oxidizing agent into the oil phase solution and mixing uniformly to obtain an emulsion solution;

[0042] (d) Adjust the temperature of the milky solution to 10-25°C (for example, 10°C, 15°C, 20°C or 25°C), pass nitrogen to remove oxygen, then add a reducing agent to initiate polymerization, and then heat preservation treatment to obtain Polymerizatio...

Embodiment 1

[0056] The water blocking agent in the present embodiment is made up of the following components by weight:

[0057] 100 parts of acrylamide, 20 parts of 2-acrylamido-2-methylpropanesulfonic acid (strength monomer), 40 parts of N-vinylpyrrolidone (strength monomer), urea methacrylate (high adhesion promoting monomer) body) 10 parts, N,N-methylenebisacrylamide (micro-crosslinking agent) 0.01 part, RM-8W (associative thickener) 1 part, N,N-dimethylacrylamide (response Body) 40 parts, methacrylamide stearyl alcohol polyoxyethylene ether (associated monomer) 2 parts, potassium hydroxide 5 parts, water 400 parts, white oil 200 parts, Span 60 (Span series emulsifier ) 15 parts, Tween 40 (Tween series emulsifier) 5 parts, n-butanol (co-emulsifier) 2 parts, DOWFAX 8390 (polymerization stabilizer) 1 part, azobisisobutyronitrile 0.2 parts, ammonium persulfate (oxidizing agent) 0.03 parts, sodium bisulfite (reducing agent) 0.05 parts, fatty alcohol polyoxyethylene ether (phase inver...

Embodiment 2

[0065] The water blocking agent in the present embodiment is made up of the following components by weight:

[0066] Acrylamide 110 parts, N-vinylpyrrolidone (strength monomer) 40 parts, N-vinyl formamide (strength monomer) 40 parts, methacrylamide ethyl ethylene urea (high adhesion promoting monomer) 15 parts Parts, 0.05 parts of pentaerythritol triallyl ether (micro-crosslinking agent), 2 parts of RM-8W (associative thickener), 60 parts of N,N-diethylacrylamide (responsive monomer), N- 4 parts of phenethyl-N-tetradecyl methacrylamide (associated monomer), 0.2 parts of potassium hydroxide, 350 parts of water, 240 parts of white oil, 21 parts of Span 80 (Span series emulsifier) , Tween 60 (Tween series emulsifier) 9 parts, hexanol (co-emulsifier) 3 parts, DOWFAX 8390 (polymerization stabilizer) 3 parts, azobisisoheptanonitrile 0.3 parts, ammonium persulfate (oxidant) 0.03 0.05 part of sodium bisulfite (reducing agent), 30 parts of fatty alcohol polyoxyethylene ether (phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com