Pearlescent contact lens

A contact lens, lens technology, applied in the field of manufacturing and ophthalmic lenses made therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A paste was prepared by mixing 20% by weight of Mearlin Micro Violet pigment (2.63 grams) with 80% enhanced blue paste (10.43 grams) containing PCN blue pigment. In a separate mixture, an effective amount of hexamethylene diisocyanate is mixed with HEMA. The mixture of 1,6-hexamethylene diisocyanate and HEMA is called "activation solution". 3.52 grams of this activation solution was then added to the paste as described above to form an ink (a mixture of paste and activation solution).

[0048] Then fill the ink into the figure 1 A flat blade is used to sweep ("squeeze") the upper surface of the cliche into the depressions of the cliche of the pattern, and the ink remaining in the depressions is transferred to the silicone printing pad. A silicone backer was then applied to the front (convex) surface of the cast unhydrolyzed hydrophilic lens. The ink-coated lens is positioned on the male portion of the mold, wherein the female portion of the mold is removed to expos...

Embodiment 2

[0052] A paste was prepared by mixing 20% by weight Mearlin Bronze pigment (2.05 grams) with 80% enhanced clear paste (8.13 grams), plus an effective amount of activation solution (2.72 grams). The lenses were printed, hydrolyzed, and cured according to the steps described in Example 1.

[0053] The color and pattern of the iris can be changed if a minimum of 25% of the area of the lens is coated with the mixture of Example 2. Coating at a minimum of about 5% area can give enhanced effect.

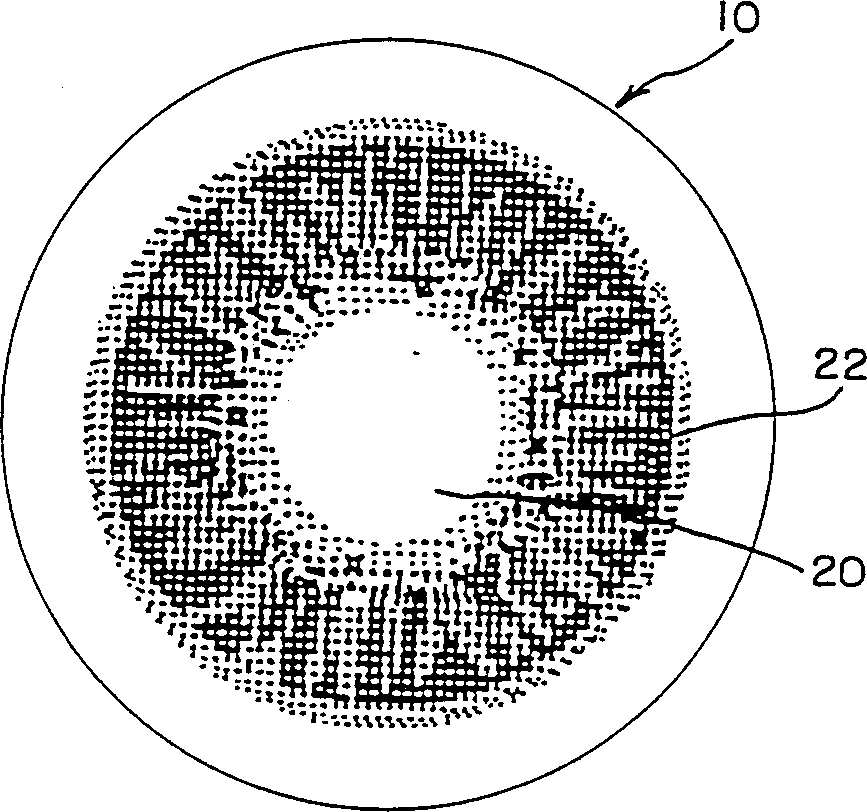

[0054] Such as figure 1 As shown, the contact lens 10 is depicted with a pearlescent pigment print layer 22 over the contact lens area of the wearer's iris, preferably all of the iris. The pupil area is generally indicated at 20 .

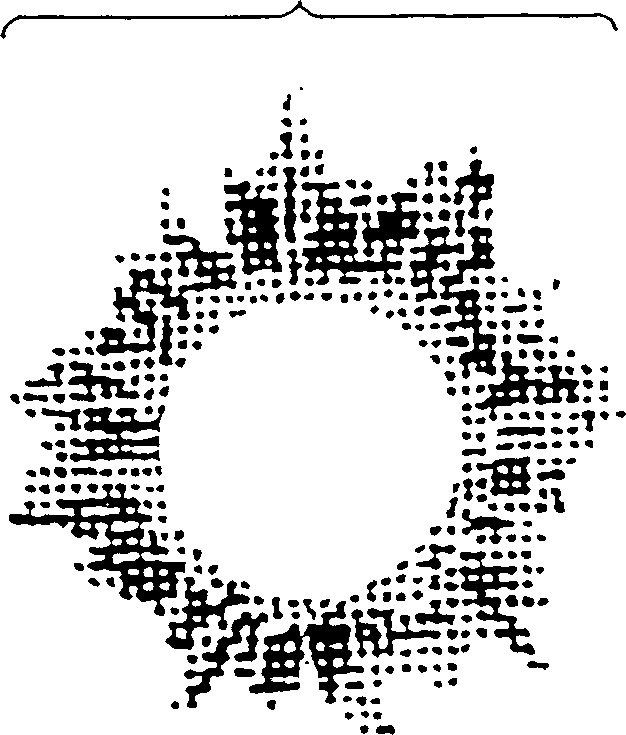

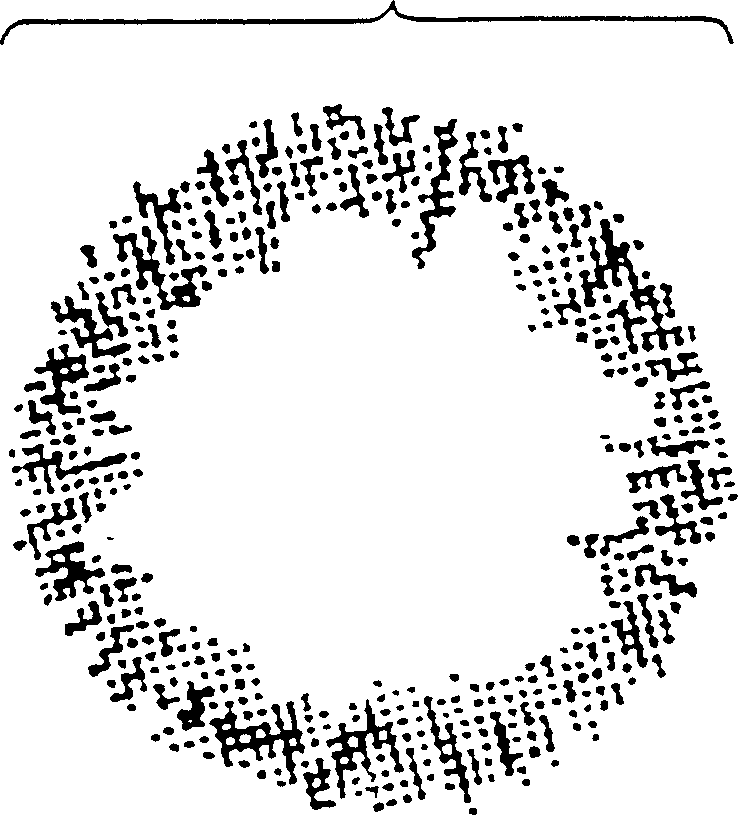

[0055] Can be printed in a discrete pattern, which allows some of the natural iris color to be seen through the uncoated or lightly coated portion of the lens. Depending on the pigment chosen, the resulting lens has a cosmetic appearance that more clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com