Method and device for determining thermal conductivity, and manufacture of thermal isolating parts

A technology of thermal conductivity and measurement method, which is applied in the direction of material thermal conductivity, etc., can solve problems such as difficult judgment, difficult product inspection, and inability to measure thermal conductivity, so as to achieve the effect of easy manufacturing and preventing thermal bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described below with reference to the accompanying drawings.

[0026] (A) Thermal conductivity measurement equipment

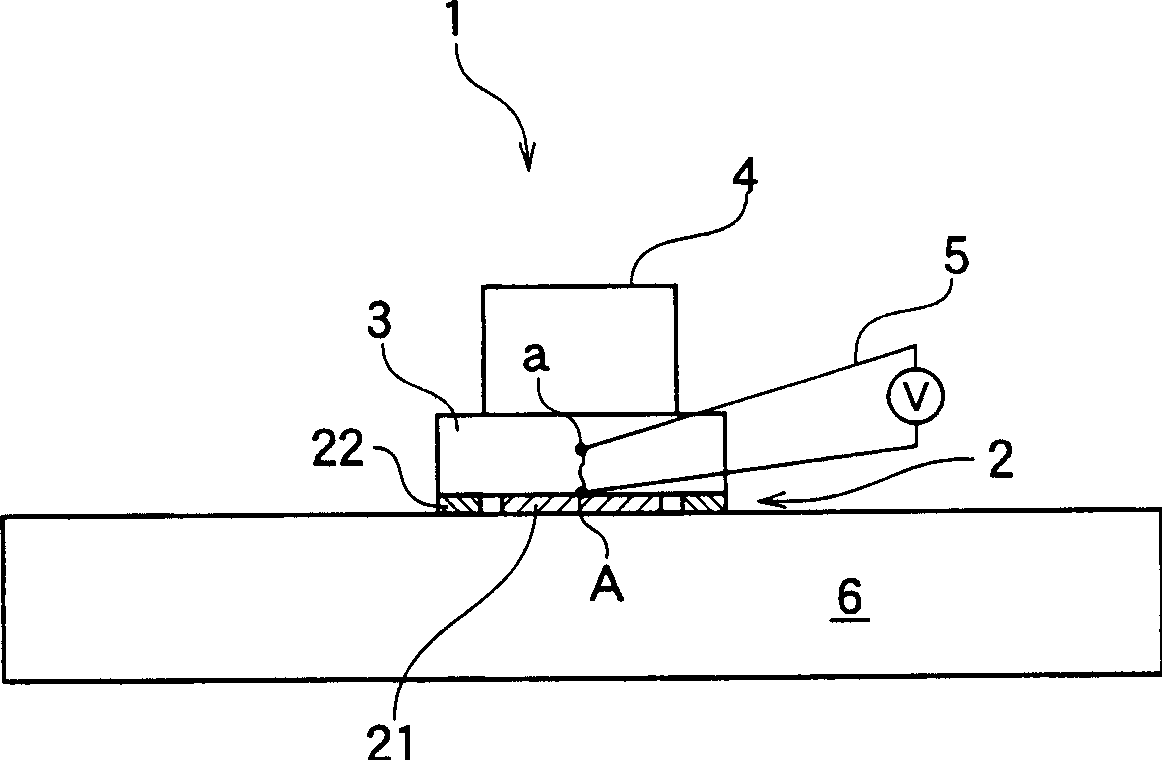

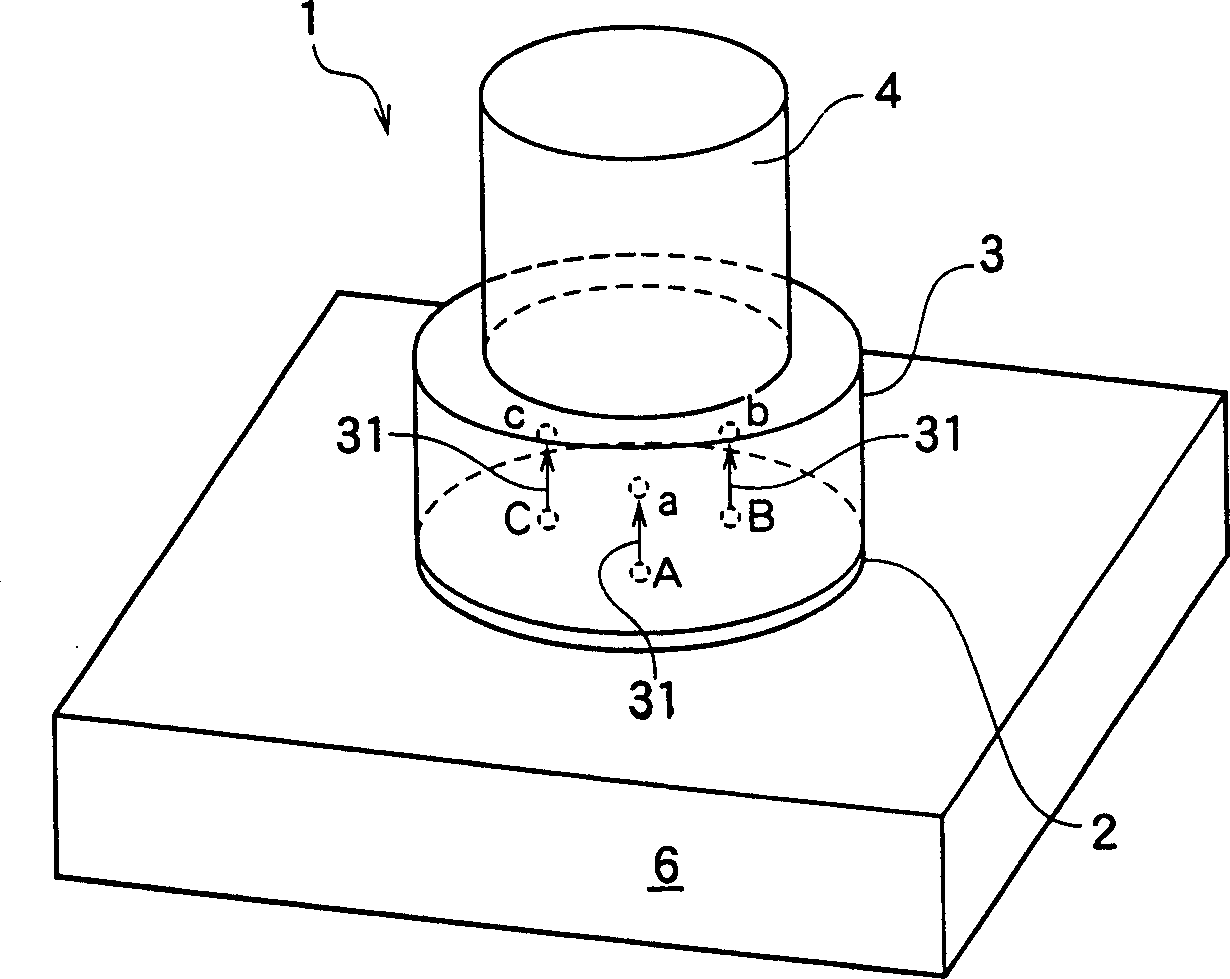

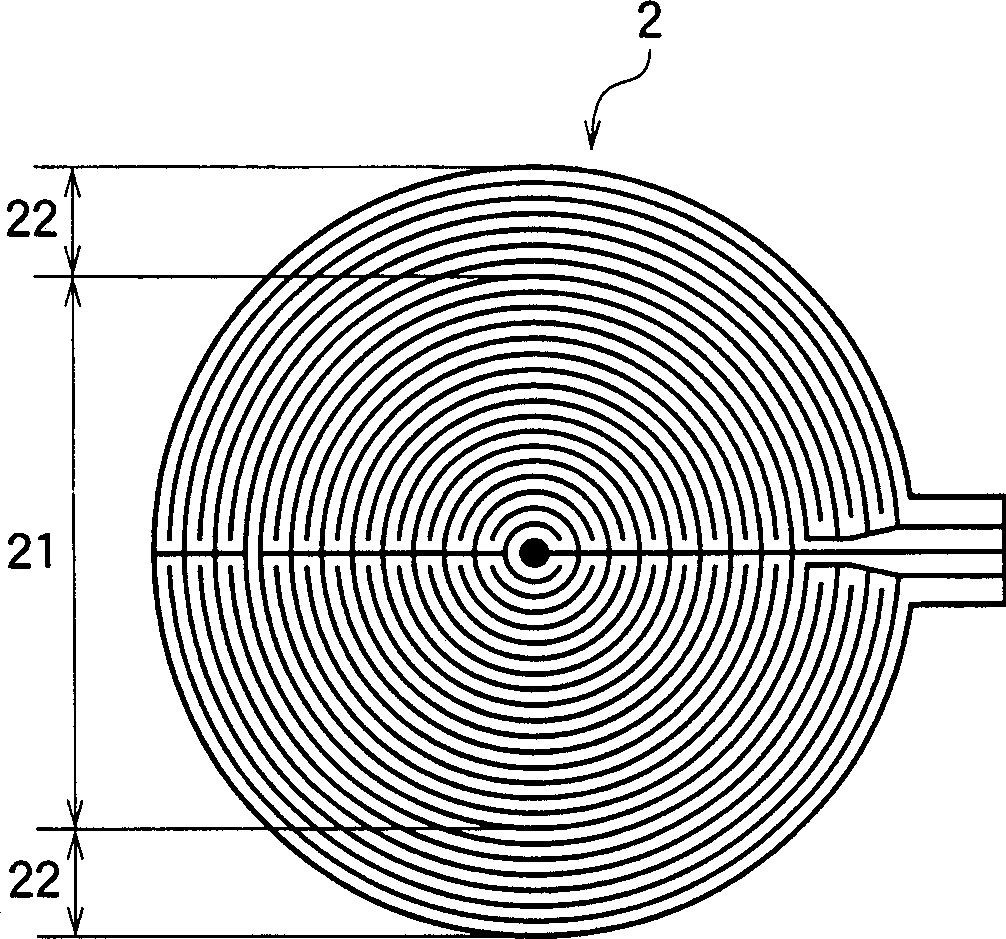

[0027] This thermal conductivity measuring device 1 is in contact with an object to be measured 6 such as a heat insulating member, and measures thermal conductivity, for example, as figure 1 As shown, it includes a thermal resistance component 3 and a heat generating device 2 . This thermal resistance member 3 is used to measure the temperature difference inside. Moreover, a vacuum heat insulating material is contained in this heat insulating material.

[0028] Through the heat generating device 2, heat is generated between the measured object 6 and the thermal resistance component 3, and the heat flows through the measured object 6 and the thermal resistance component 3, which can be generated according to the heat flow 31 flowing through the inside of the thermal resistance component 3. The temperature diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com