Label and method for produicng labels and device for implementing said method

A label and fabric technology, applied in the field of labels and their production and implementation devices, can solve the problems of waste of weaving width, worthless and unsightly labels, etc., and achieve the effect of improving wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

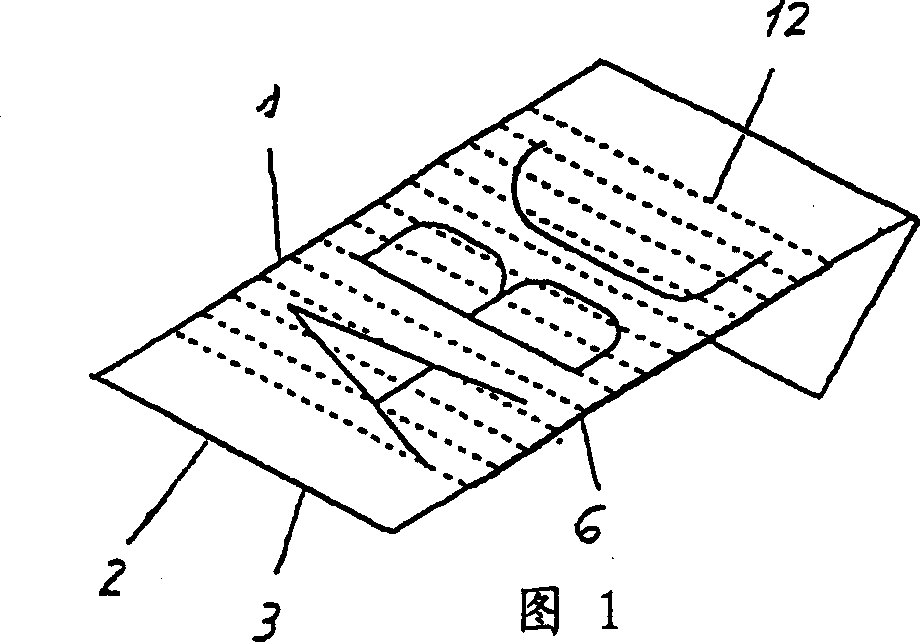

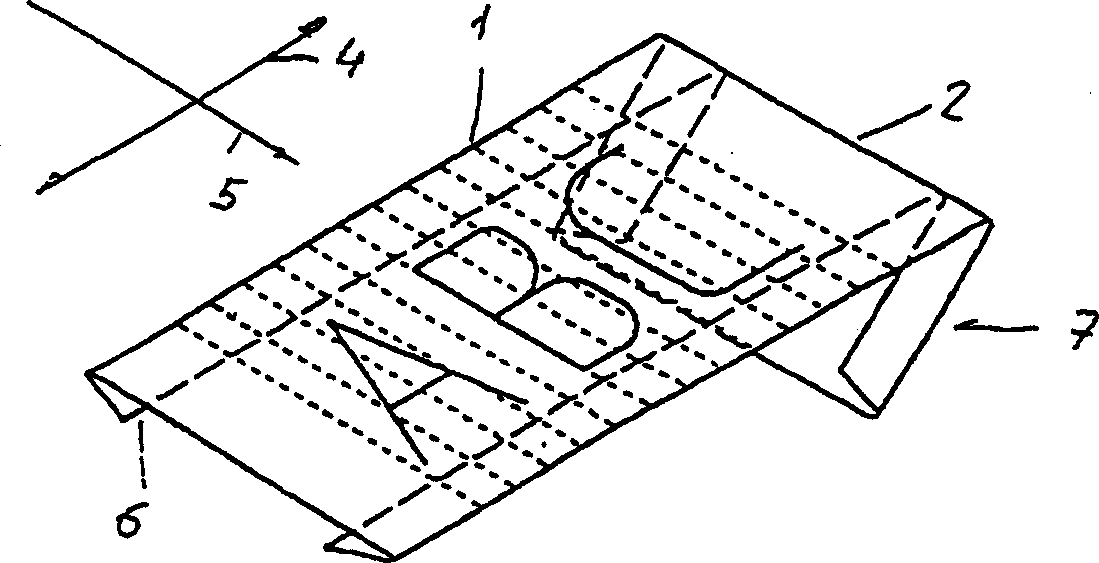

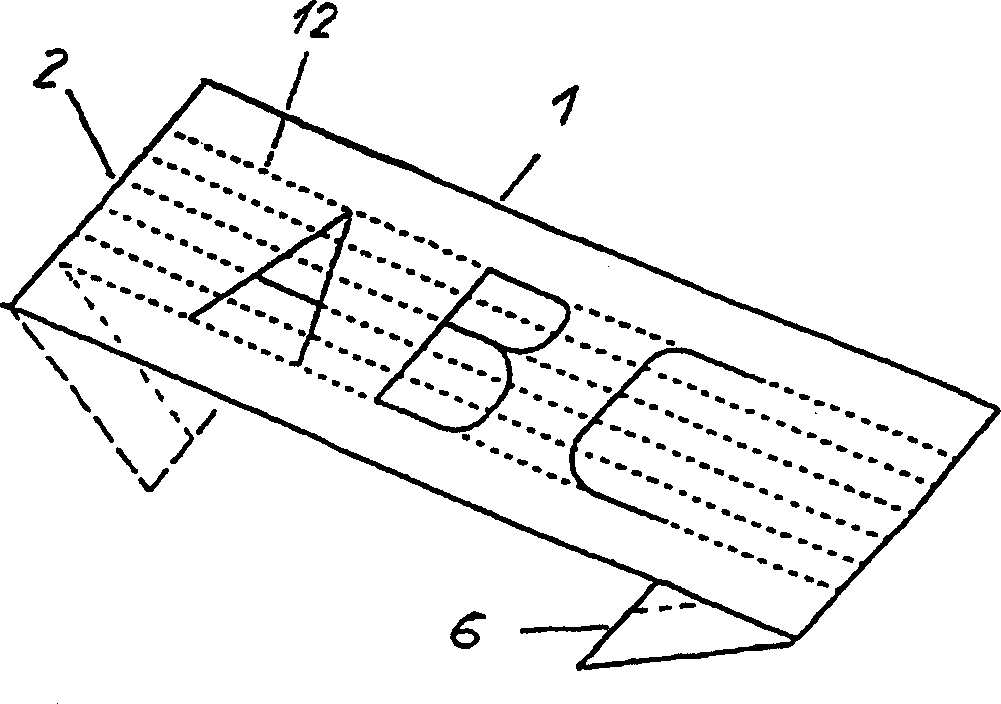

[0027] image 3 The label of the present invention is shown, and the difference in the warp direction and the weft direction of the known label according to FIGS. 1 and 2 can be clearly seen from the display, and it is explained by referring to the following description of FIGS. 4 to 8.

[0028] The label conventionally has a quadrilateral shape with two unfolded longitudinal sides 1 and two foldable narrow sides 2. The label is composed of a backing fabric 11 and a plurality of decorative weft yarns 12, and the decorative weft yarns 12 form a pattern in the label area 13, so the margin 14 of the backing fabric exists on the longitudinal edges and is combined in the form of floating. The back side of the label. The label weaving causes the warp yarn 4 to extend transversely, and the weft yarn 5 is parallel to the longitudinal edge 1 of the label. The narrow side 2 of the label cut by the thermal cutting device has a trimmed edge. At the trimmed edge, the backing fabric 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com