Label and method for producing the same

A label and weft technology, applied in the field of labels and the production of the labels, can solve the problems of high cost, loose longitudinal yarns, and special expenditures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

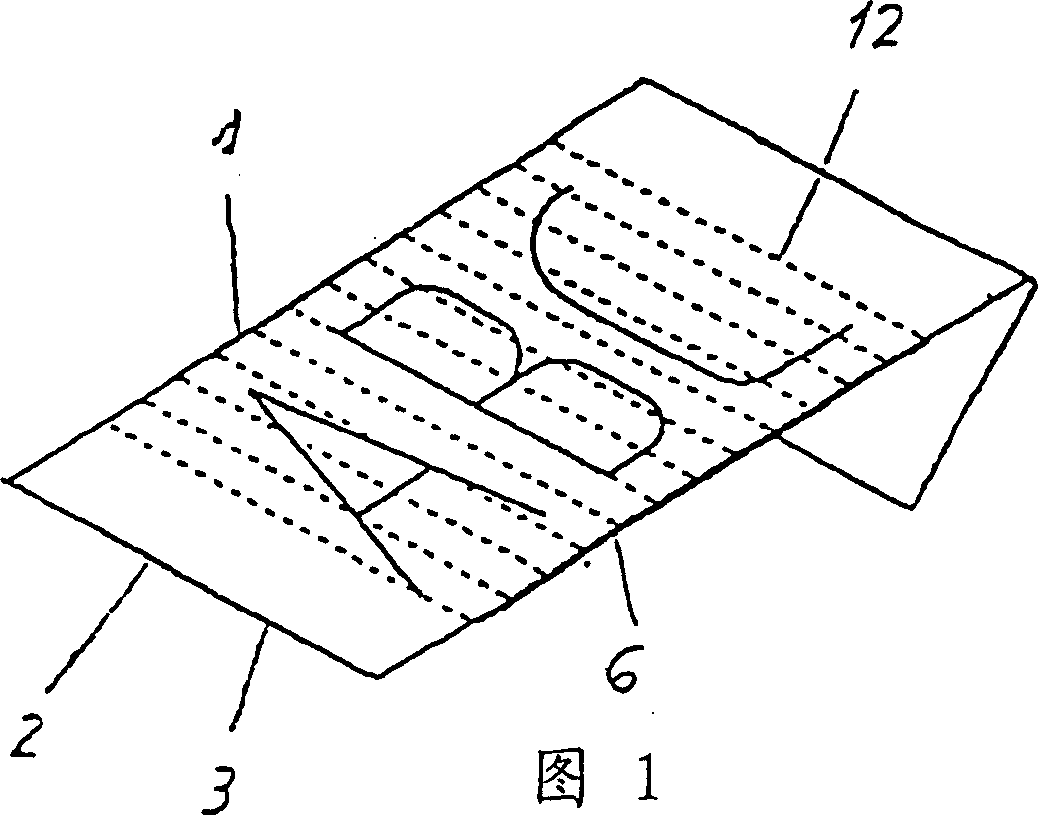

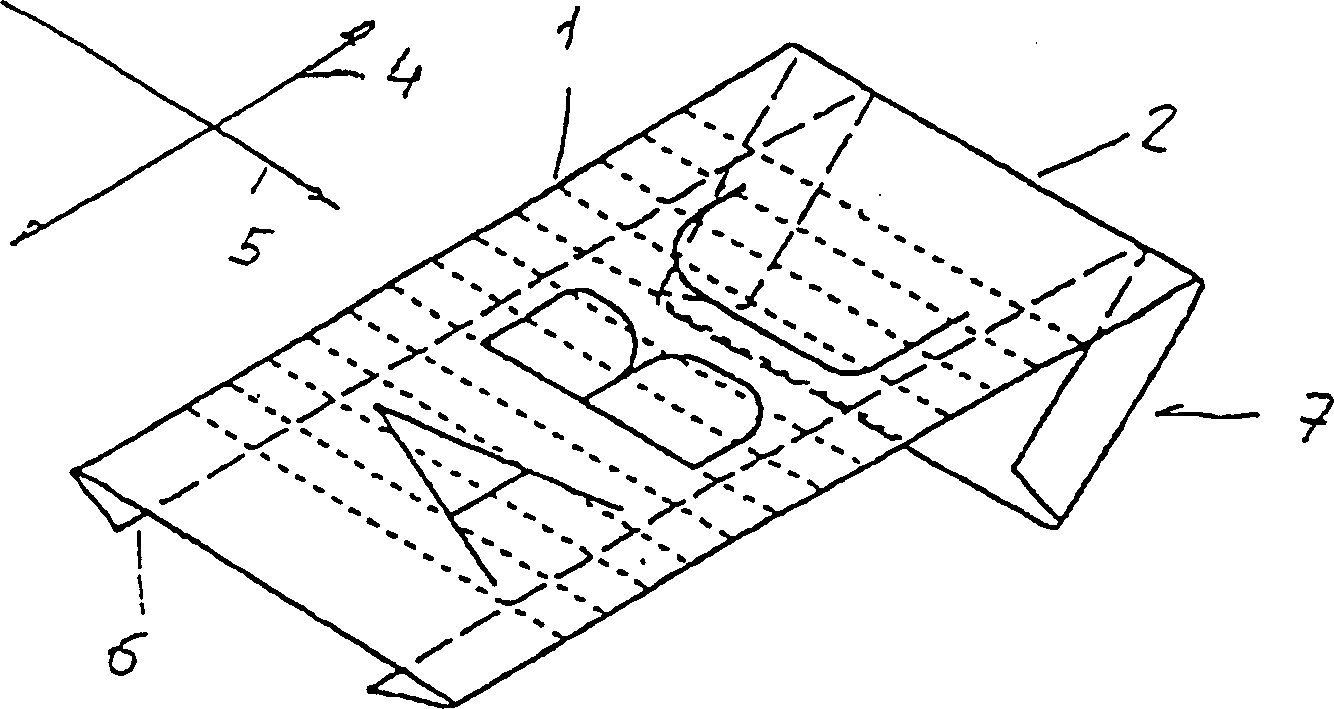

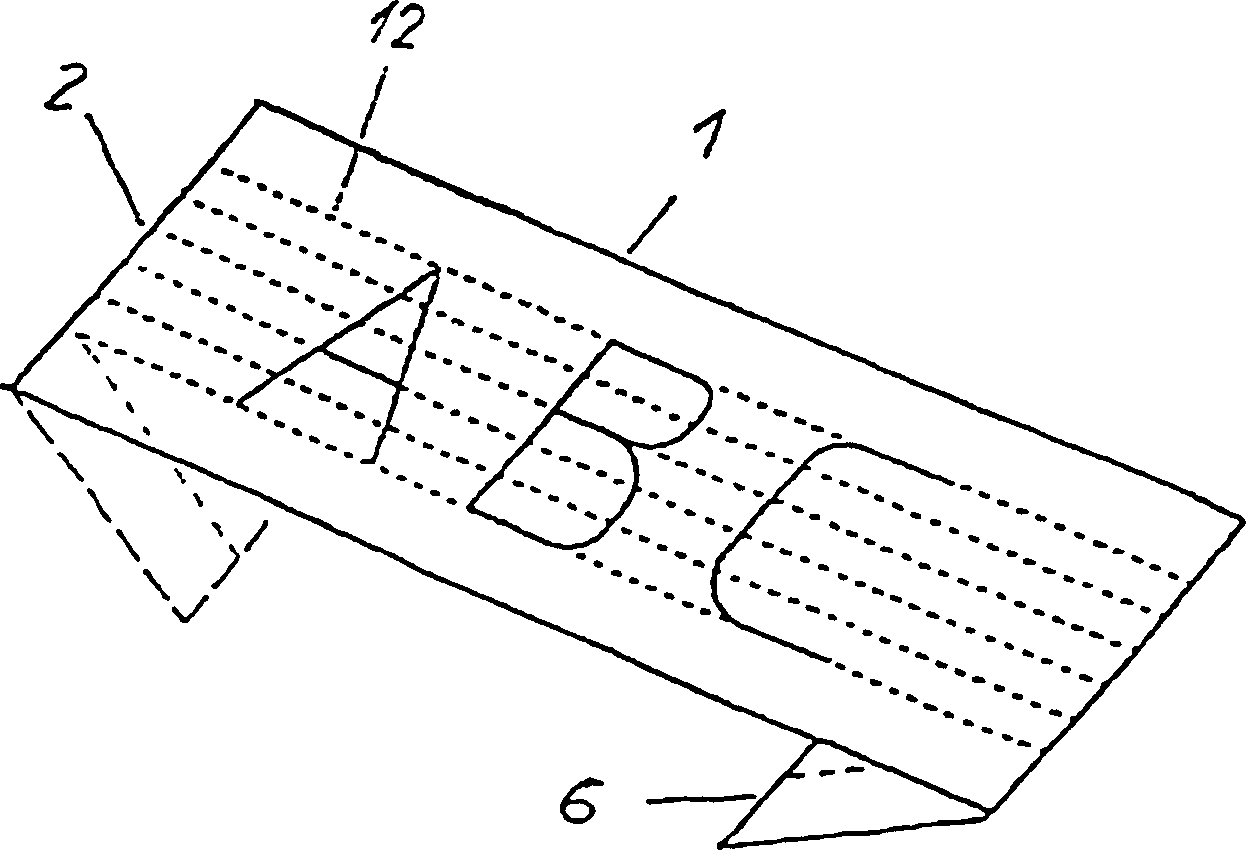

[0026] image 3 A label according to the invention is shown from which the differences in the warp and weft directions of the known label according to FIGS. 1 and 2 are clearly seen and explained by the following description with reference to FIGS. 4 to 8 .

[0027] Labels are conventionally quadrangular in shape with two non-folded longitudinal sides 1 and two foldable narrow sides 2 . The label consists of a backing fabric 11 and a plurality of decorative weft yarns 12, which form a pattern in the label area 13, so that margins 14 of the backing fabric are present on the longitudinal edges and are bonded in the form of floating weaves. label on the back side. The label is woven so that the warp yarns 4 run transversely and the backing weft yarns 5 run parallel to the longitudinal edge 1 of the label. The narrow edge 2 of the label cut by the thermal cutting device has a cut edge where the backing fabric 11 and the decorative weft yarn 12 floating on the back side of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com