Device for changing needle rod range of sewing machine

A needle bar stroke and sewing machine technology, applied in the field of stroke devices, can solve the problems that the eccentric pin cannot rotate relatively and is fixed on the needle bar crank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

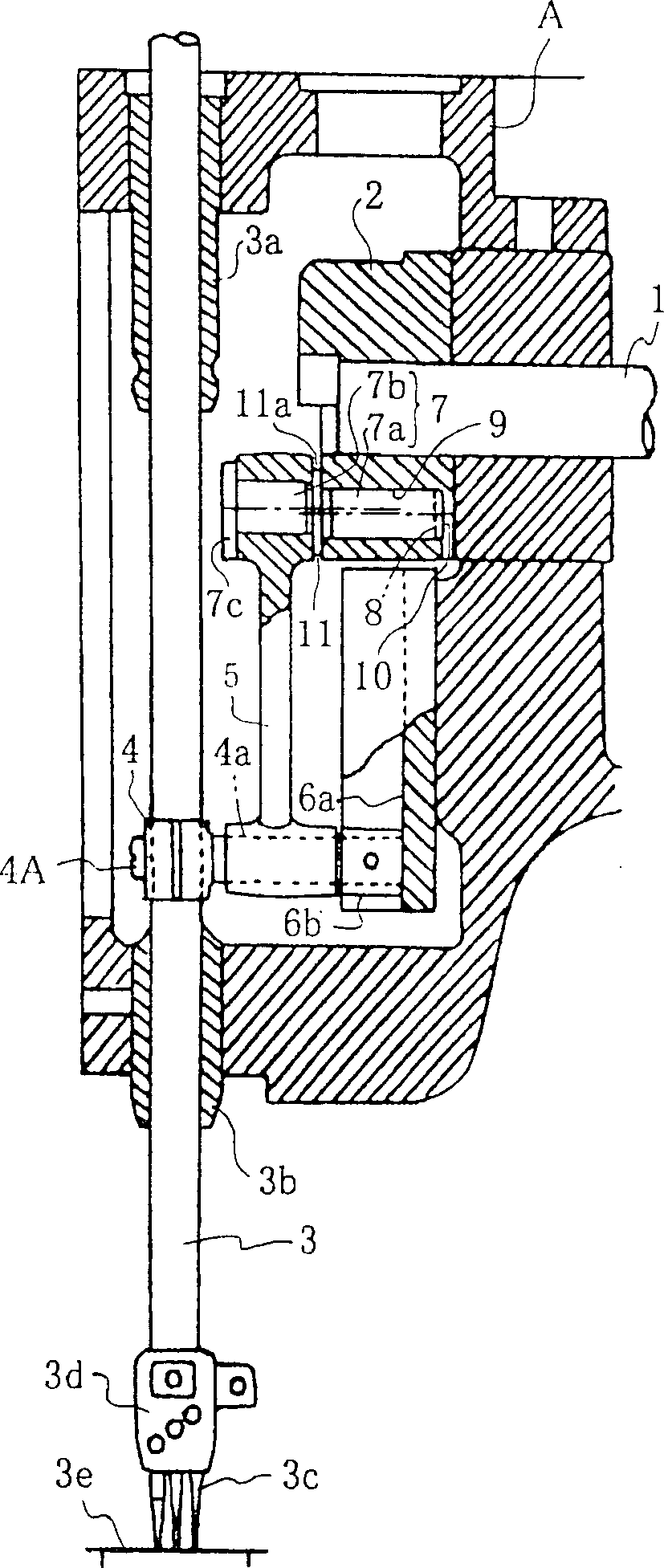

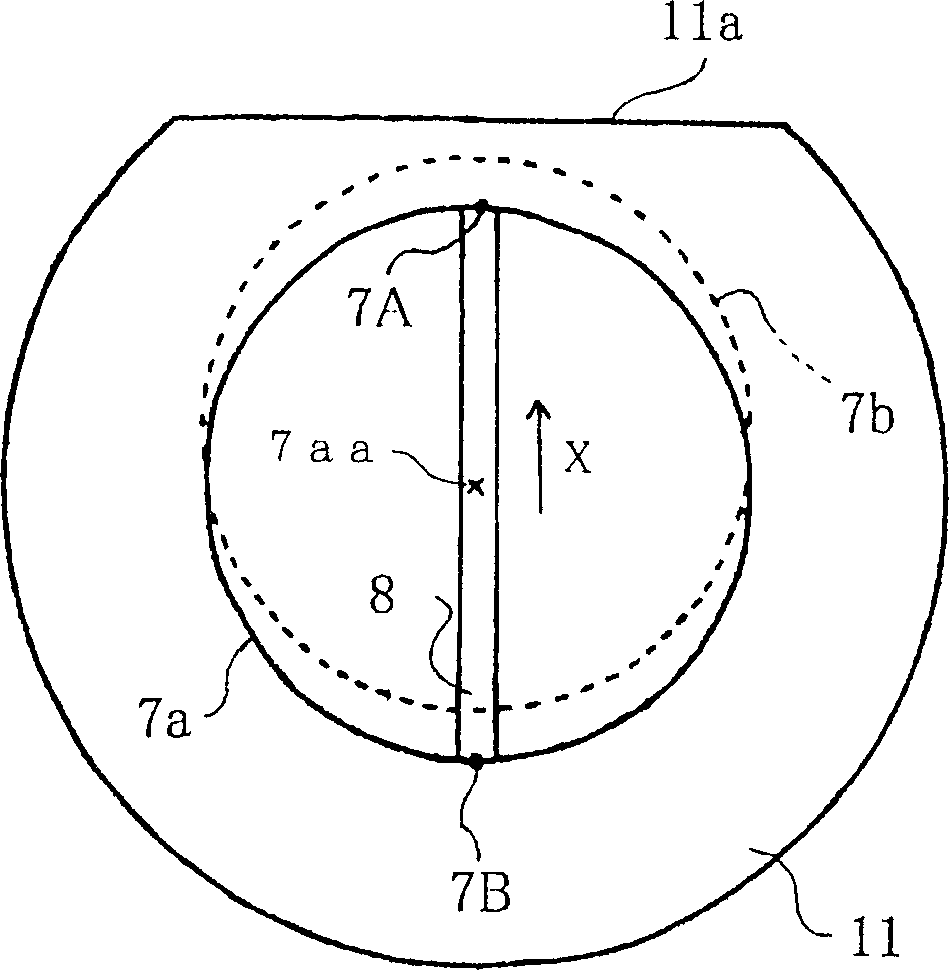

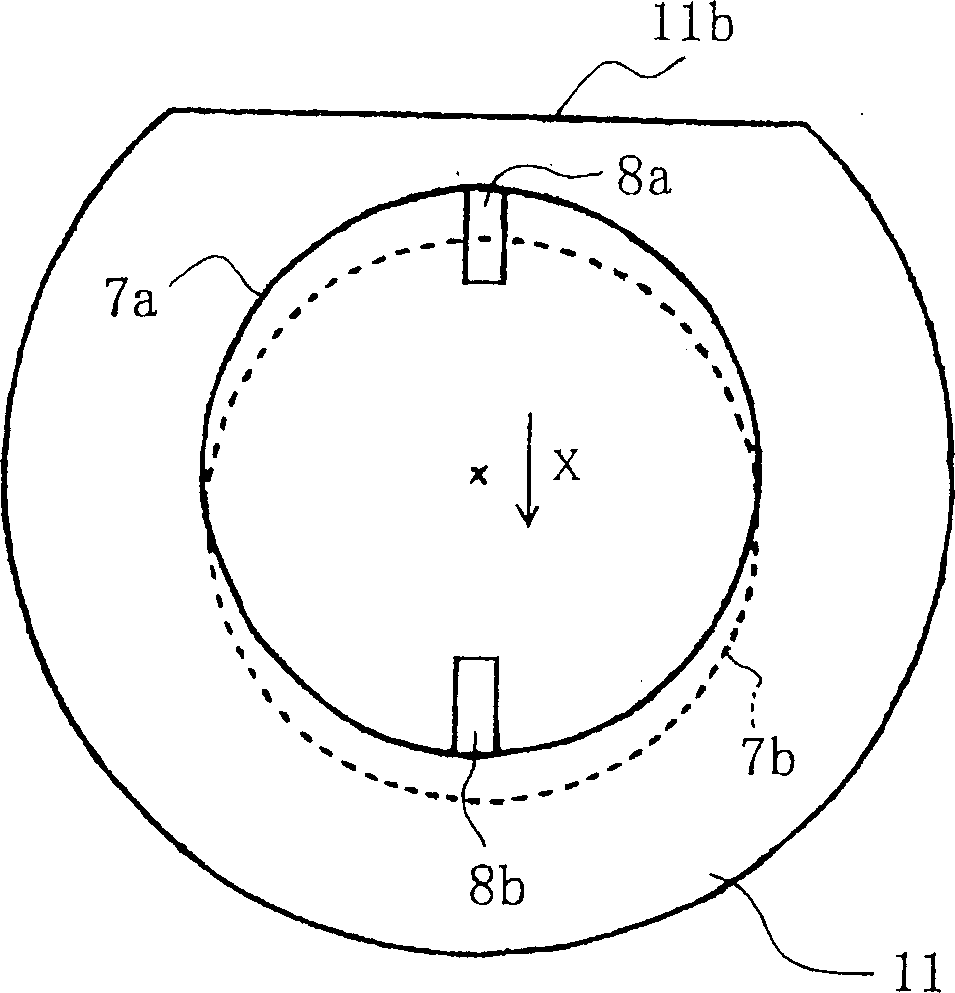

[0011] Next, embodiments according to the present invention will be described based on the drawings. figure 1 It is a partial sectional view showing a part of the sewing machine according to the present invention. The upper shaft 1 is pivotally supported in the sewing machine head A substantially horizontally, and is linked with a driving motor (not shown) to rotate in the same direction. A needle bar crank 2 is installed on the top of the upper shaft 1 . A needle bar 3 that can slide is arranged in the sheaths 3a, 3b fixed up and down in the sewing machine head A. The needle 3c is mounted on a needle clamp 3d fixed to the lower end of the needle bar 3, and passes through a needle plate 3e provided on the sewing machine table (not shown) when the needle bar 3 descends. Install clamp 4 with screw 4A in the middle of needle bar 3. The jig 4 has a substantially horizontally extending shaft 4 a rotatably pivoting the link 5 . The top end of the shaft 4a is vertically slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com