Organic electroluminance display

A display device and electroluminescence technology, applied in electroluminescence light source, lighting device, light source, etc., can solve the problems of high manufacturing cost, increase manufacturing cost, weaken the competitiveness of organic electroluminescent display panel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

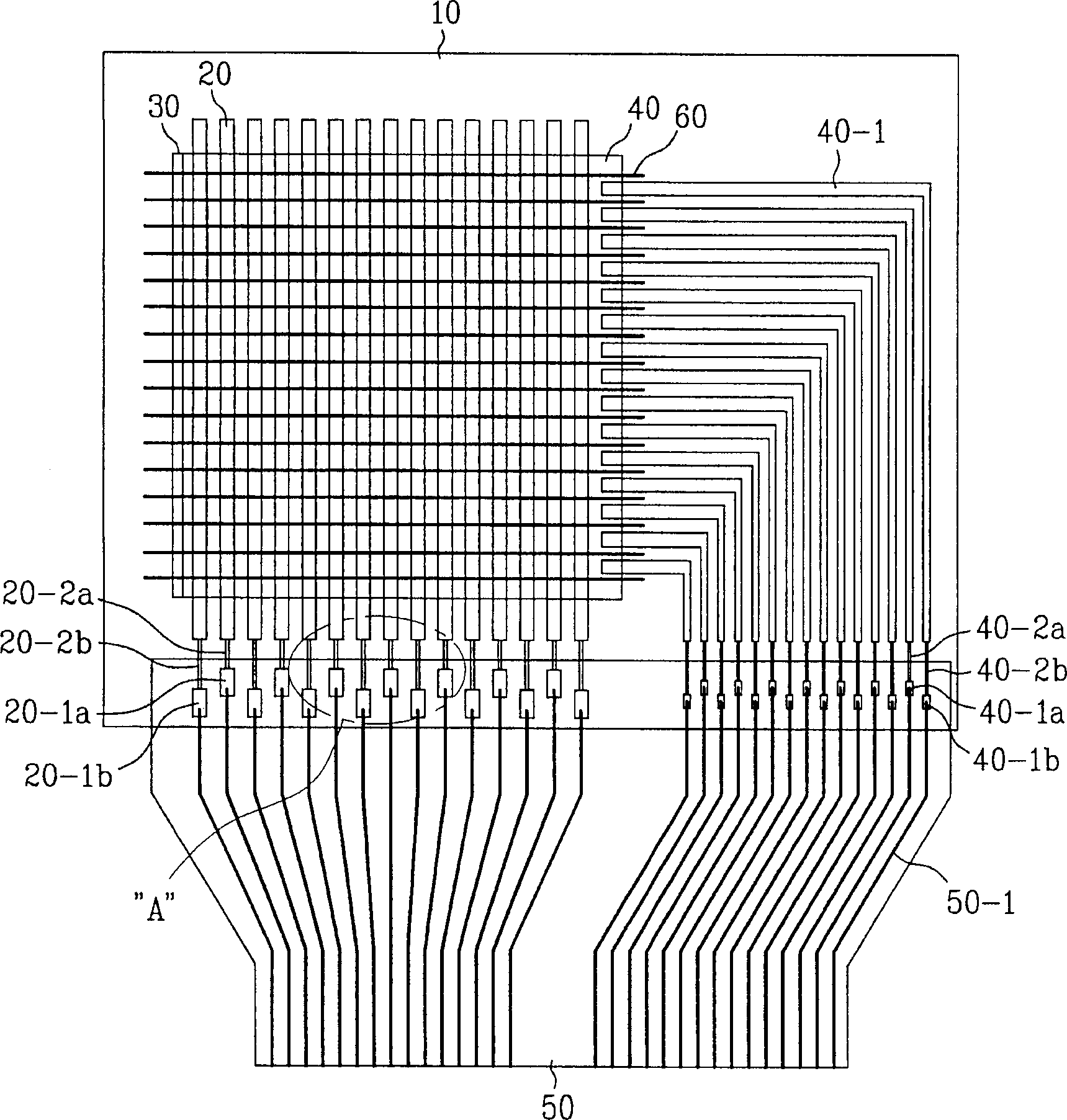

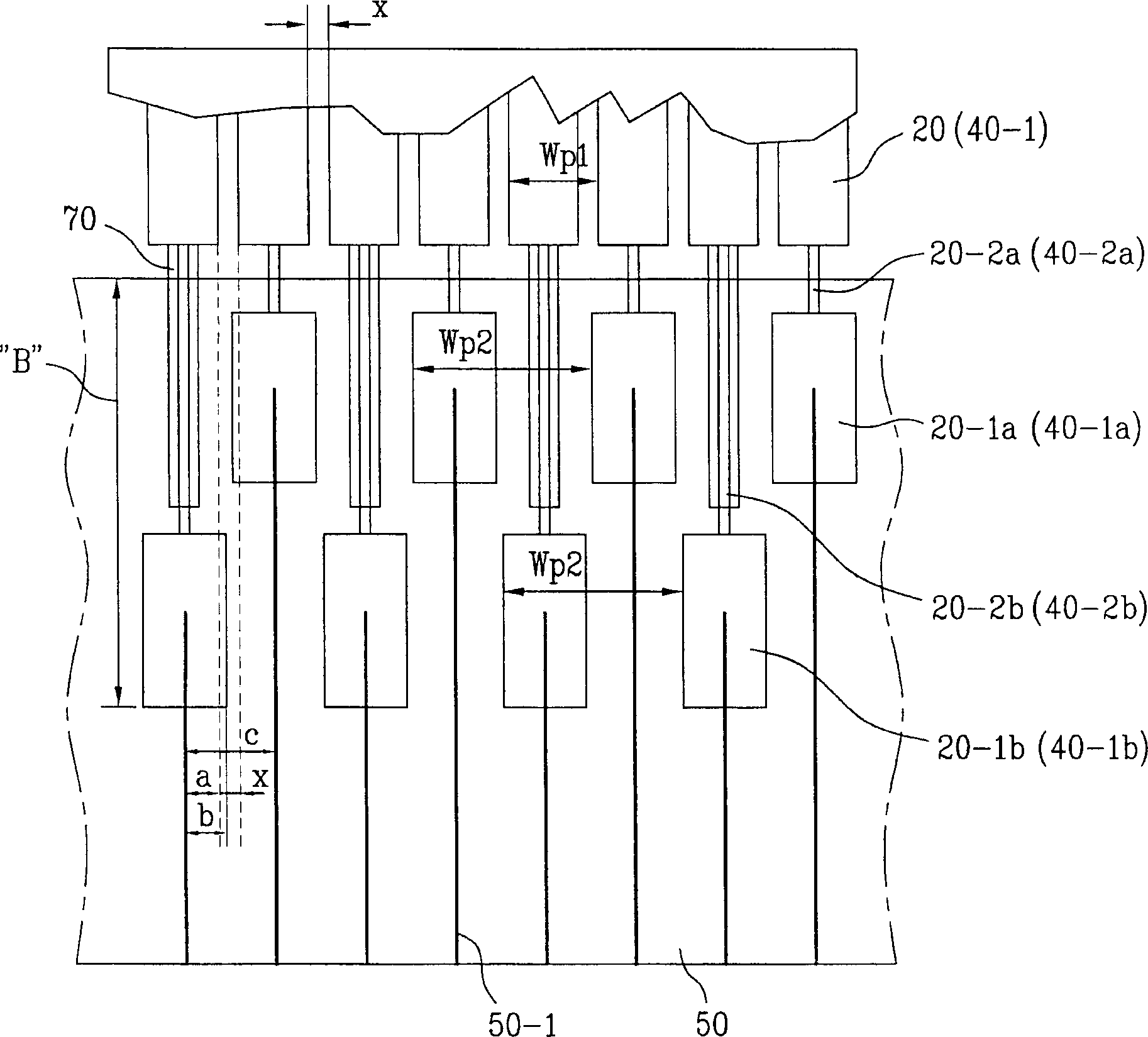

[0017] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers have been used throughout the drawings to designate the same or like parts.

[0018] An organic electroluminescent display panel according to the present invention will be described with reference to the accompanying drawings.

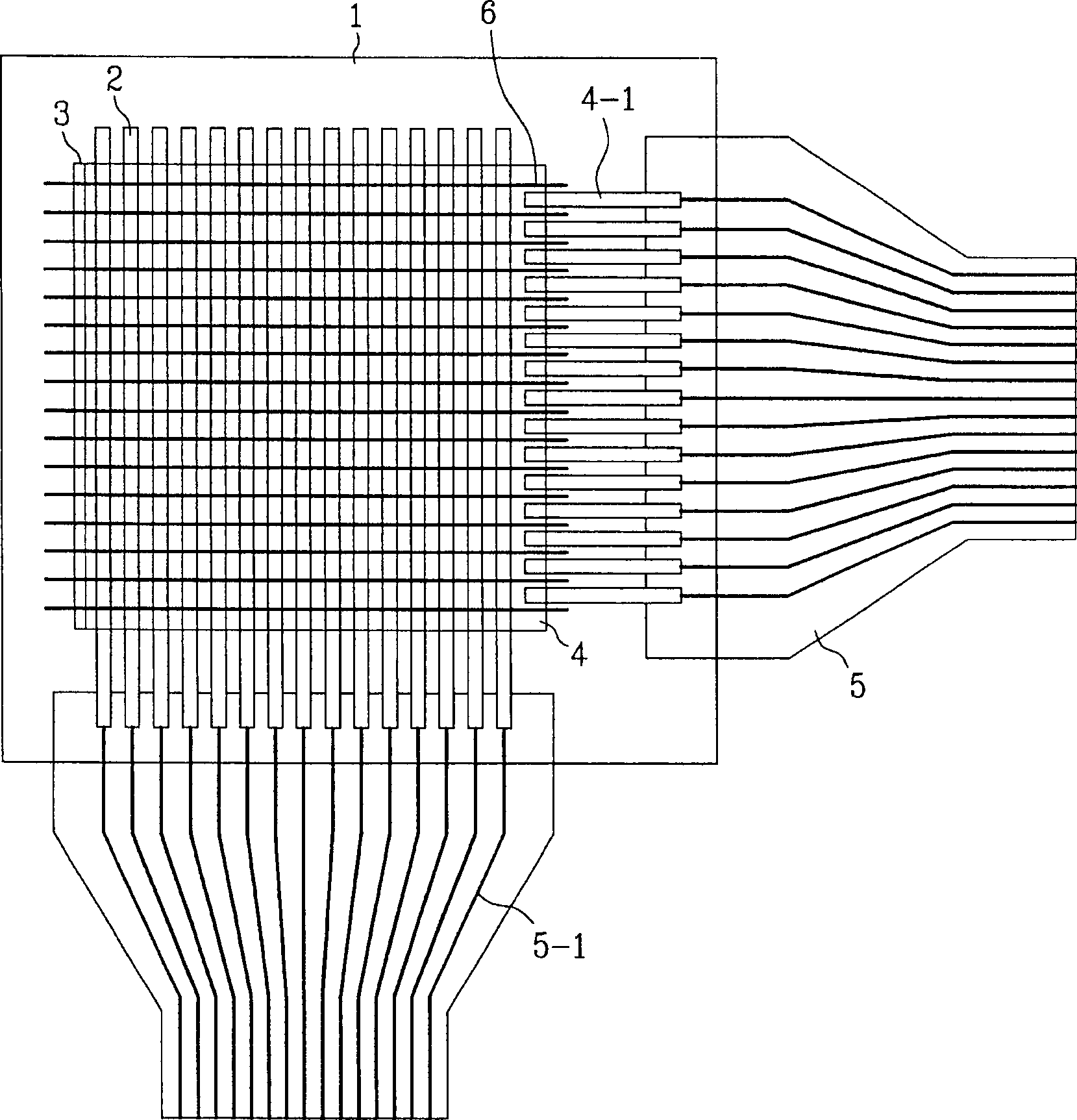

[0019] figure 2 is a plan view showing an organic electroluminescent display panel equipped with a thin film type device according to the present invention.

[0020] Such as figure 2 As shown, the organic electroluminescent display panel includes a transparent substrate 10, an organic electroluminescent layer 30, a connecting portion 40-1 of the second electrode, a shield 60, first electrode wires 20-2a, 20-2b and a second electrode Two electrode wires 40-2a, 40-2b.

[0021] At this time, the organic electroluminescence layer 30 is formed as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com