Mower

A lawn mower and grass bag technology, applied in the direction of lawn mowers, harvesters, cutters, etc., can solve the problems of loud noise, dust discharge, pressure loss, etc., and achieve the effect of reducing noise and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

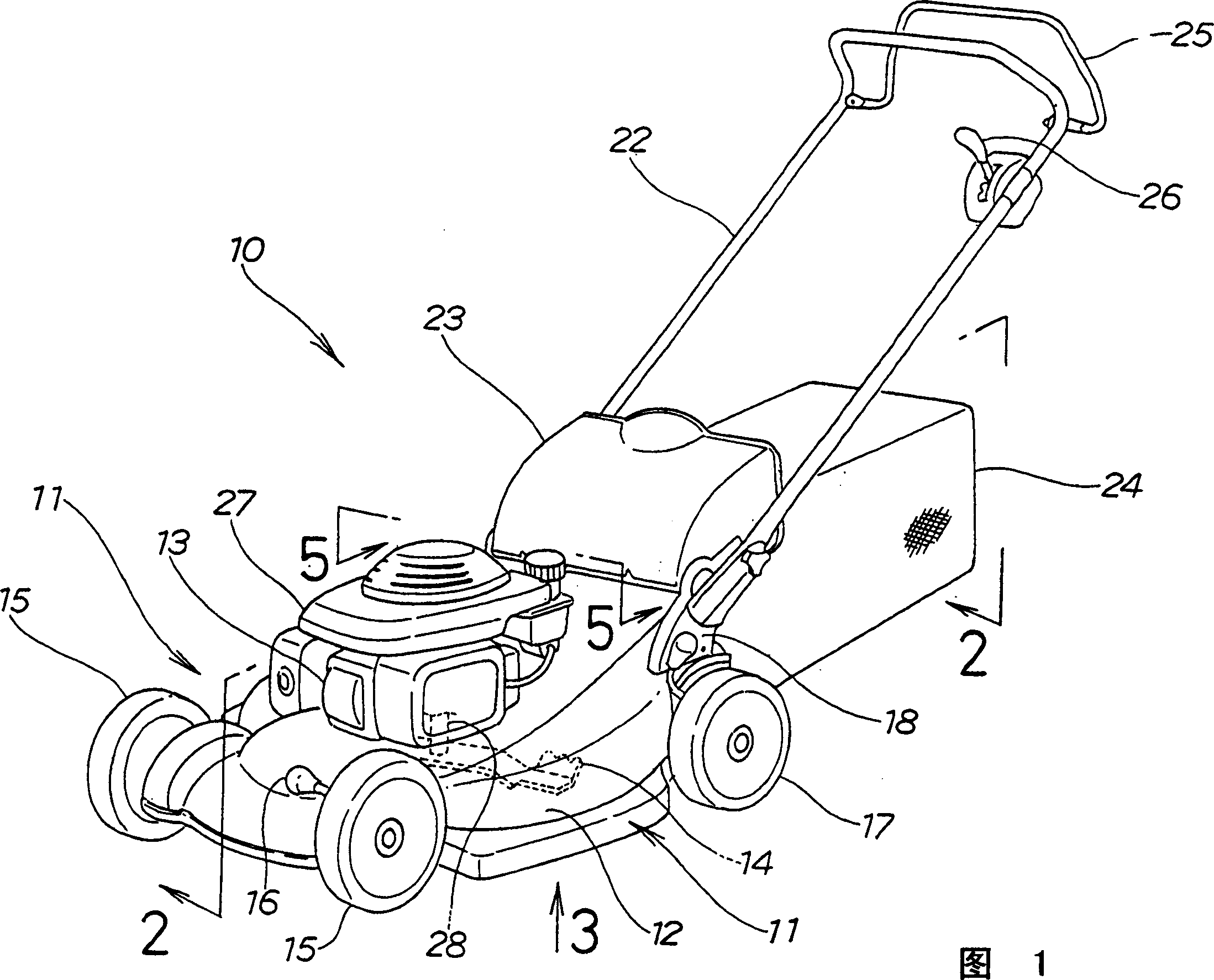

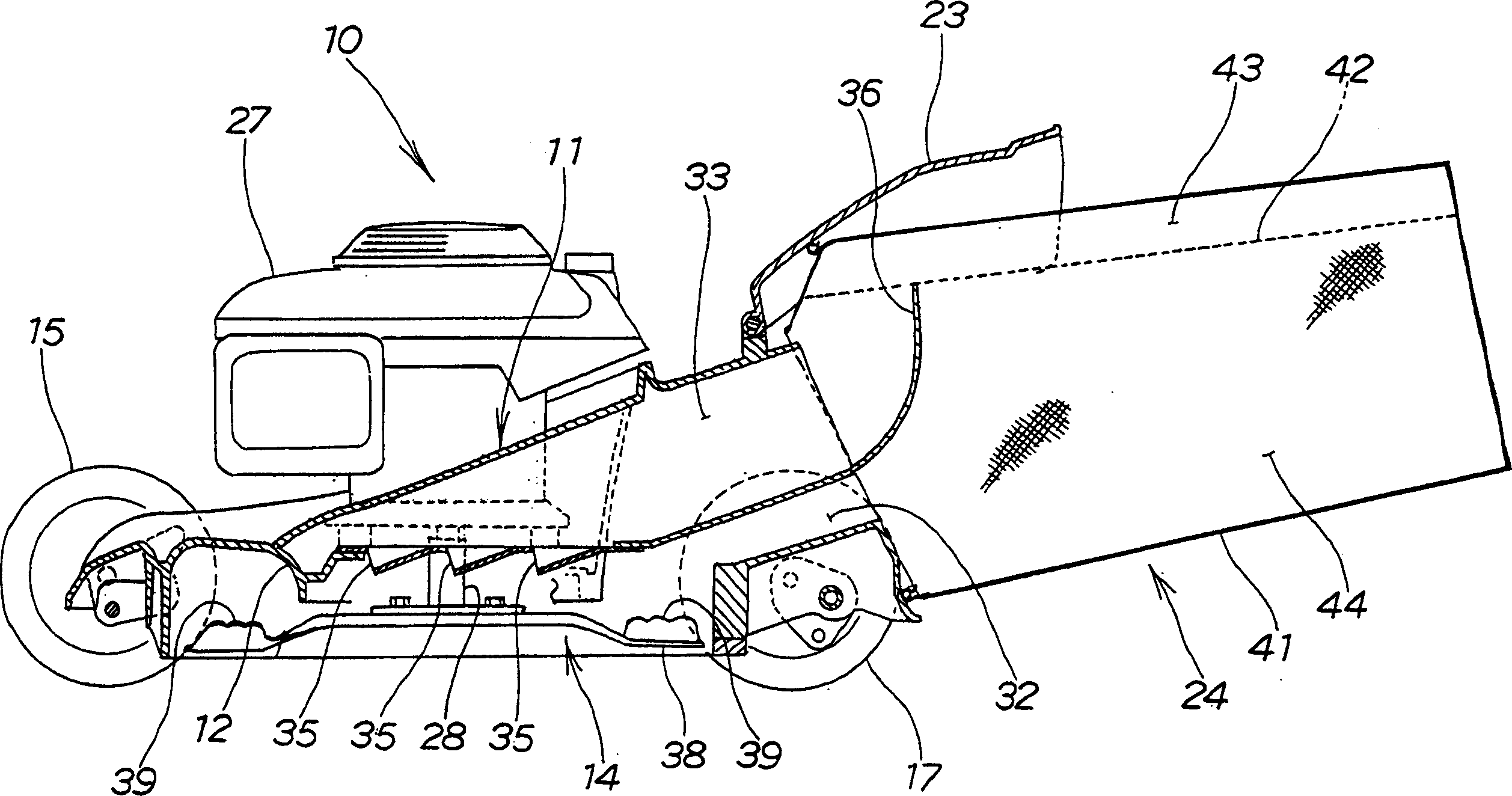

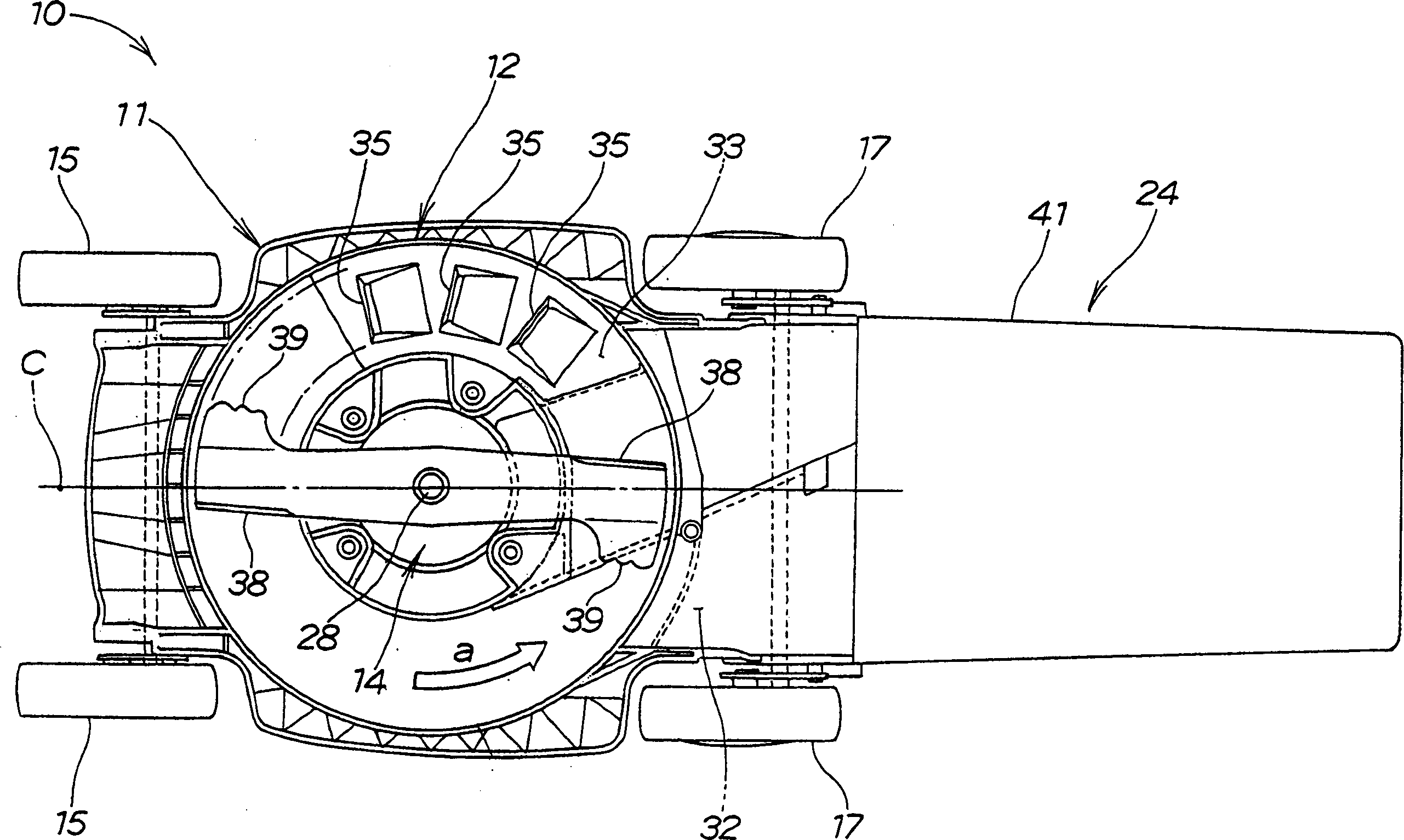

[0025] Referring to FIGS. 1 and 2 , a lawnmower 10 of the present embodiment is a self-propelled lawnmower having an engine 13 as a driving source for rotating a cutter blade 14 and driving a rear wheel 17 . The engine 13 is mounted on the mower body 11 . A top cover 27 is attached to an upper portion of the engine 13 . The cutter blade 14 is attached to a rotary shaft 28 which is an output shaft of the motor 13 . The rotation of the cutter blade 14 is controlled with a cutter lever 25 . The operator grasps the handle 22 and operates the shift lever 26 for mowing work. Rotation of the cutter blade 14 transports the cut grass into the grass bag 24 .

[0026] Reference numeral 15 denotes a front wheel, reference numeral 16 denotes a front height adjusting mechanism, and reference numeral 18 denotes a rear height adjusting mechanism. The grass cover 23 is installed between the mower body 11 and the grass bag 24, and is used to prevent the broken grass from being discharged ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com