Inhaling holding device

A technology for holding device and air, applied in electrical components, transportation and packaging, furnaces, etc., can solve the problems of wafer W prone to cracks and damages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below with reference to the drawings.

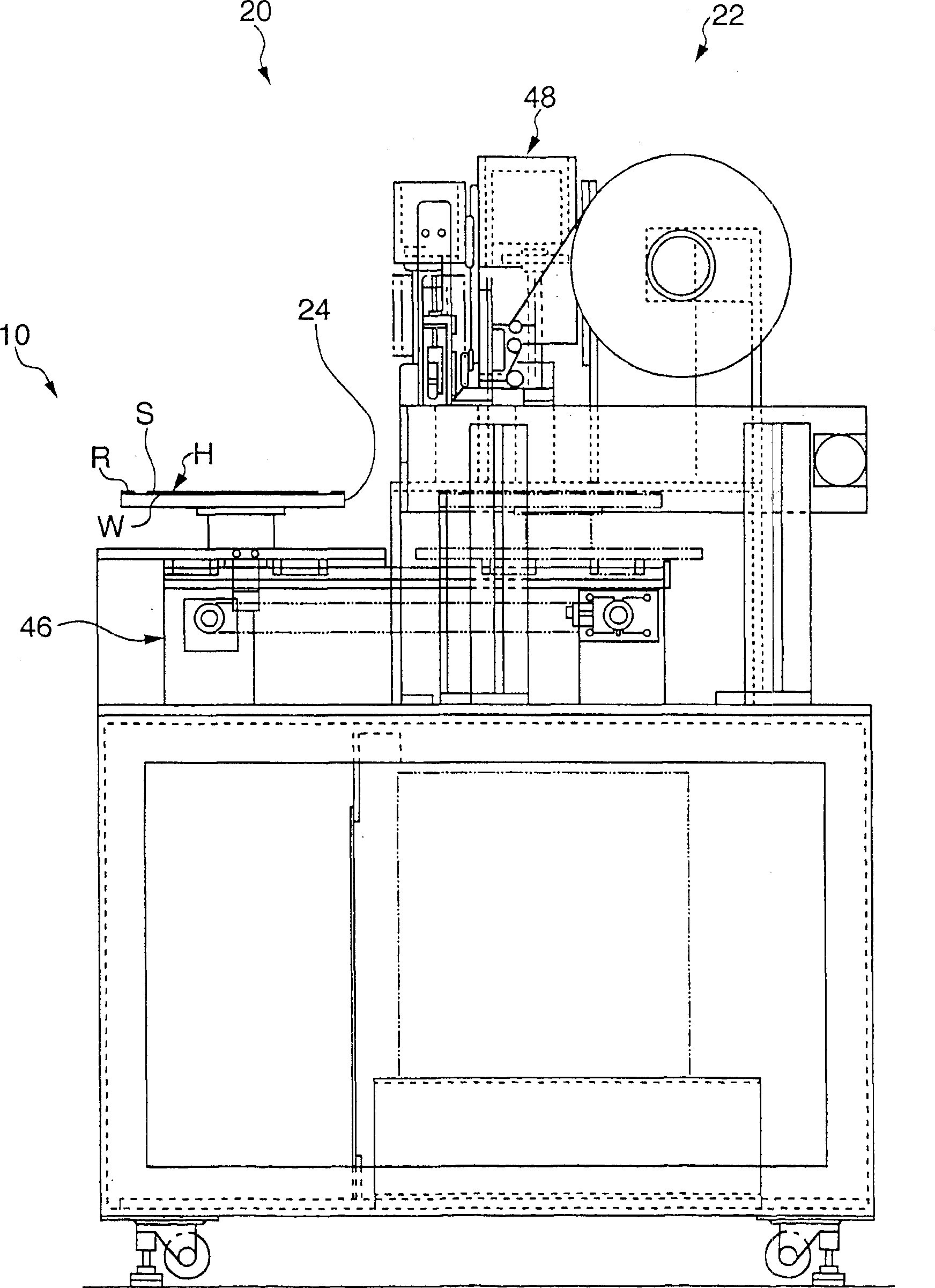

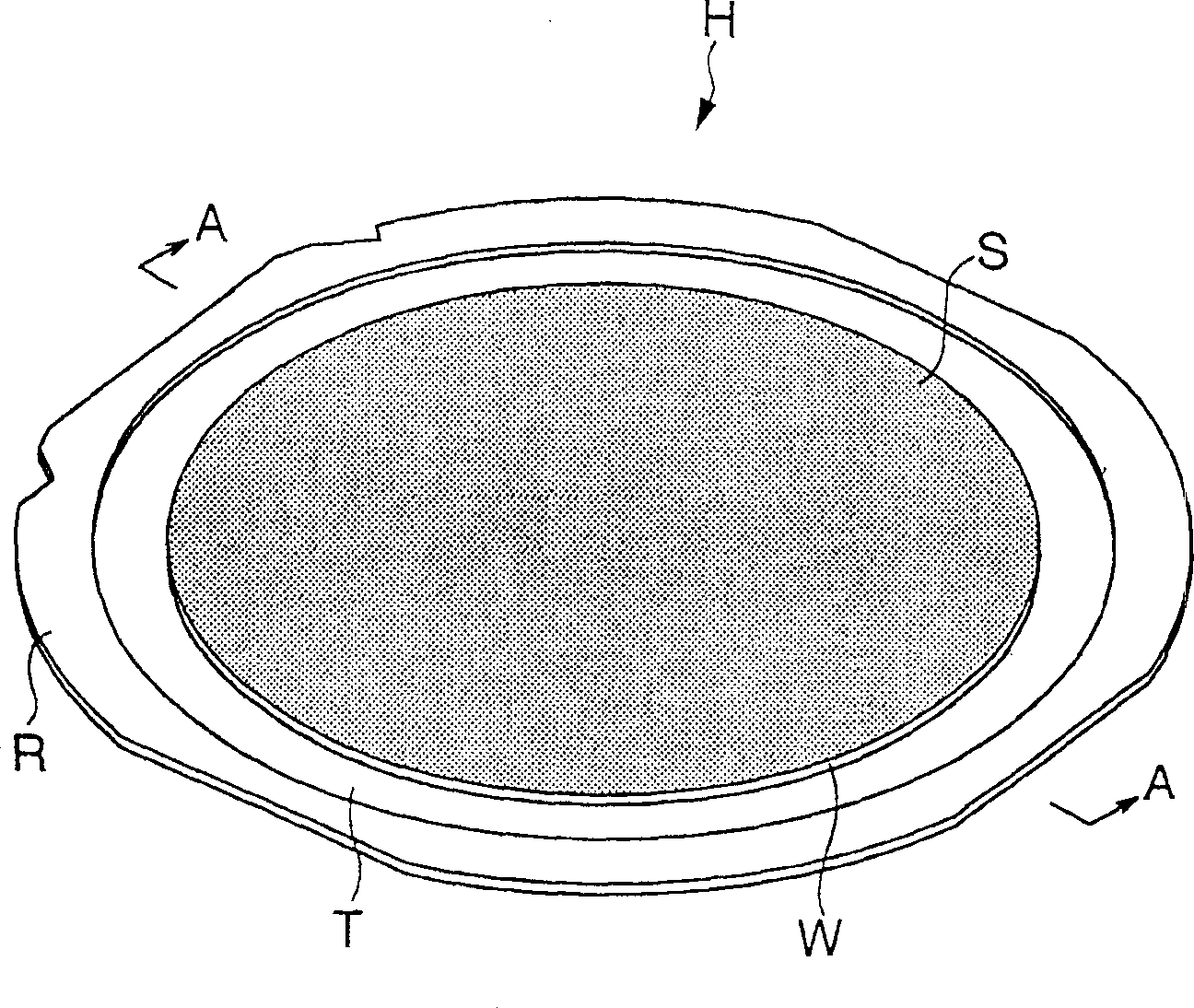

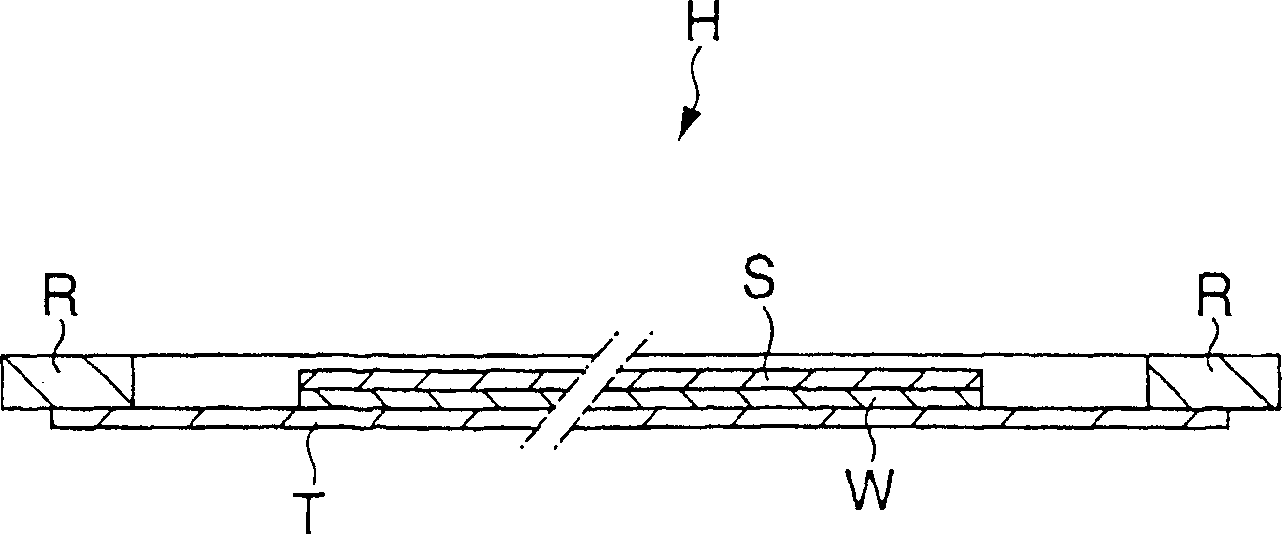

[0024] exist figure 1 , shows a schematic side view of a stripping device 20 to which a suction holding device 10 according to the invention is added. exist figure 2 , a schematic perspective view of a wafer holding device H as an object to be applied to the stripping device 20 is shown. exist image 3 in, showing figure 2 An enlarged vertical section view of . In these figures, the wafer holding device H comprises a generally disk-shaped wafer W, a protective layer S, a dicing tape T, and an annular frame R, the front (upper side) of the above-mentioned disk-shaped wafer W constituting a A circuit surface, a protective layer S is laminated on the circuit surface of the wafer W, a dicing tape T is bonded on the back surface of the wafer W, and a ring frame R is bonded along the peripheral portion of the dicing tape T.

[0025] The stripping device 20 is a device for au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com