Fibre-optical fixator, fibre-optical adapter and fibre-optical process equipment with location device

A fixer and optical fiber technology, applied in the coupling of optical waveguides, instruments, optics, etc., can solve problems such as fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] best practice

[0077] Other features of the present invention will become clearer through the description of the following preferred embodiments, and the given preferred embodiments are used to explain the present invention rather than limit the present invention.

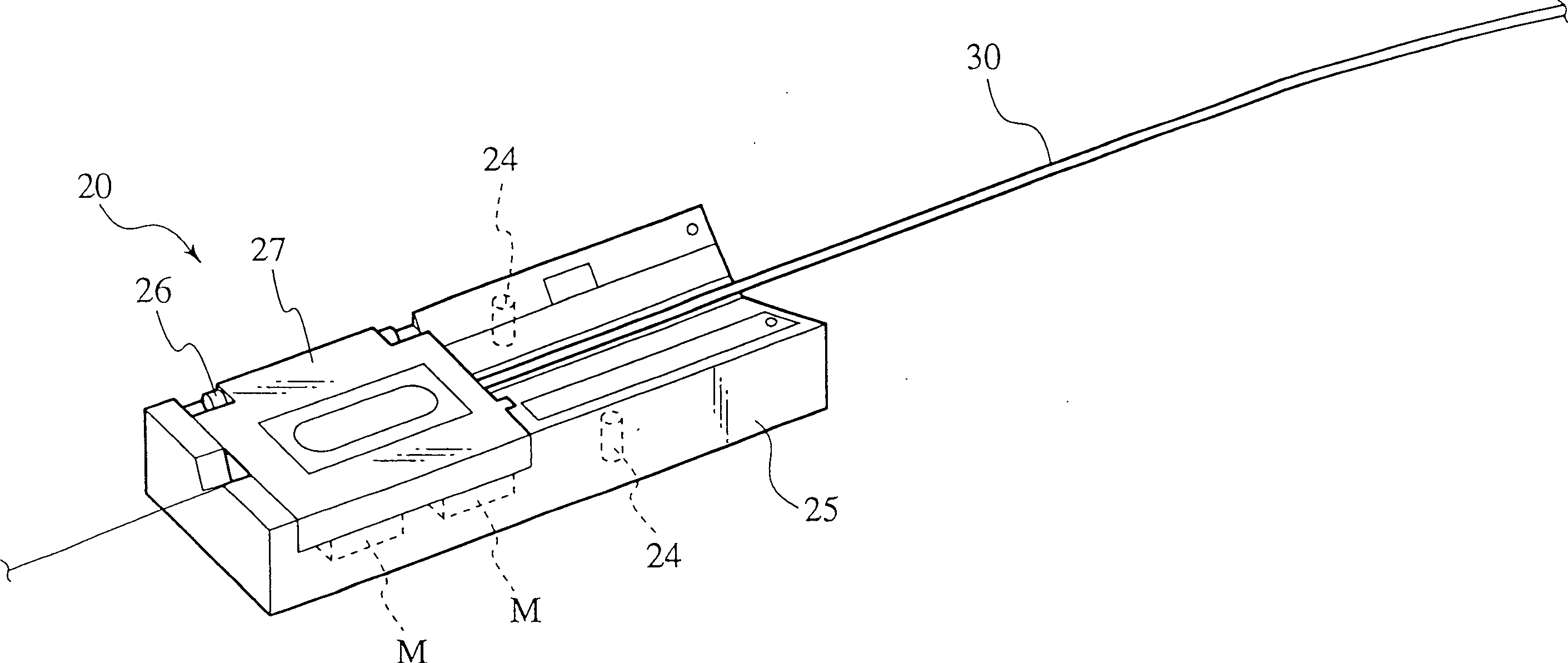

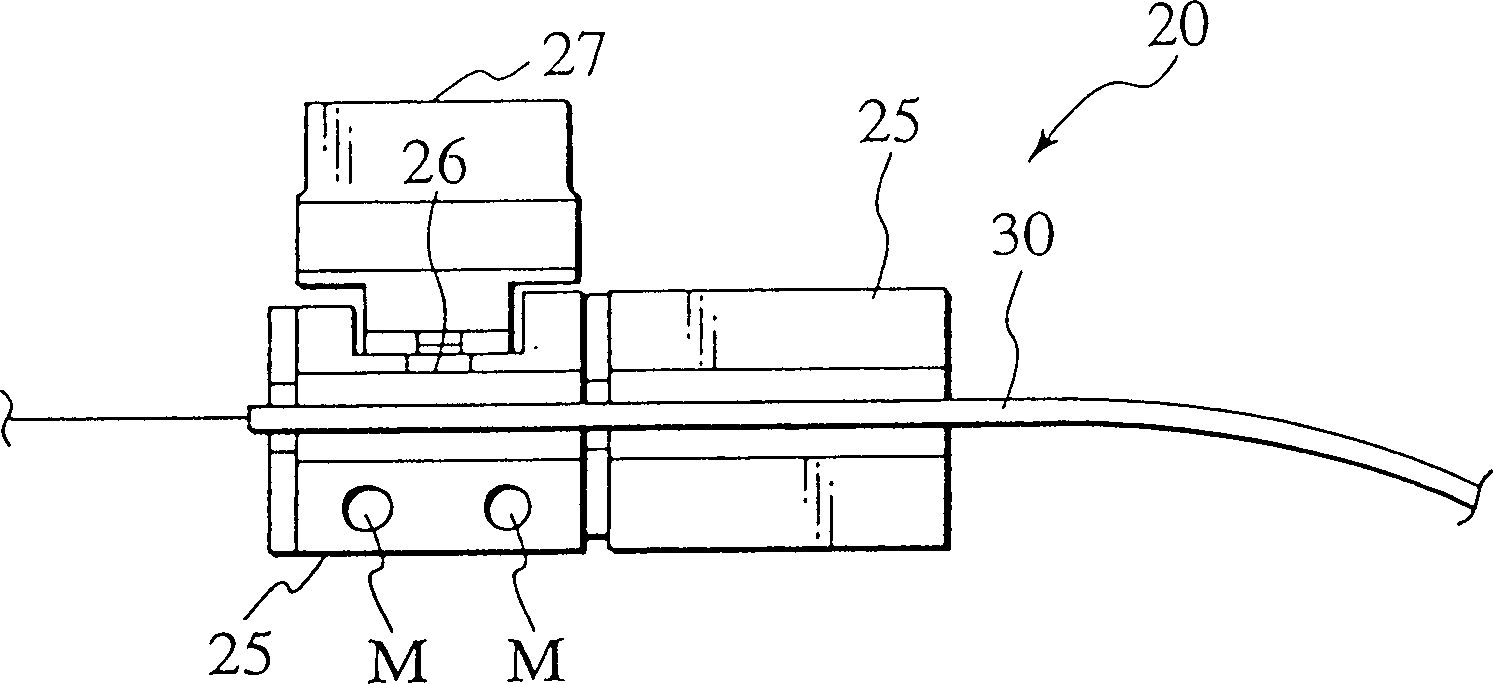

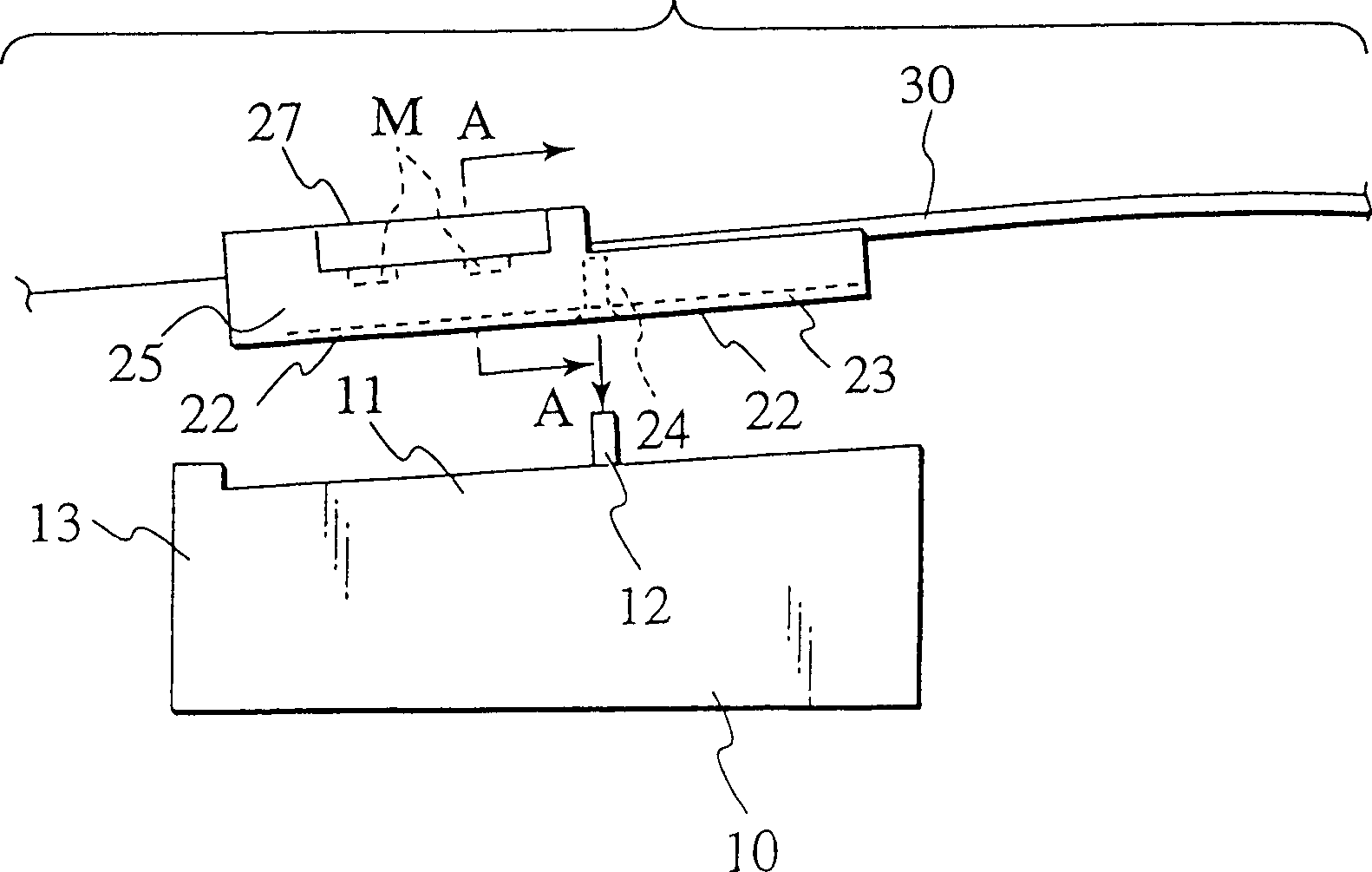

[0078] The fiber holder with a positioning mechanism, the fiber adapter with a positioning mechanism and the fiber processing device with a positioning mechanism will be described in detail below in conjunction with the accompanying drawings of the present invention. Subsequent descriptions show that the fiber holder of the present invention is fixed on various processing devices such as a fiber fuser, a high-strength shell stripper, a high-strength cutter, an ultrasonic cleaner, and the like. However, the present invention is not limited by these structures. For example, the fiber holder of the present invention can be applied to various fiber processing devices.

[0079] first embodiment

[0080] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com