Device for heat/moist exchange

An exchange equipment, heat and humidity technology, applied in the field of heat/humidity exchange equipment, can solve problems such as increasing pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

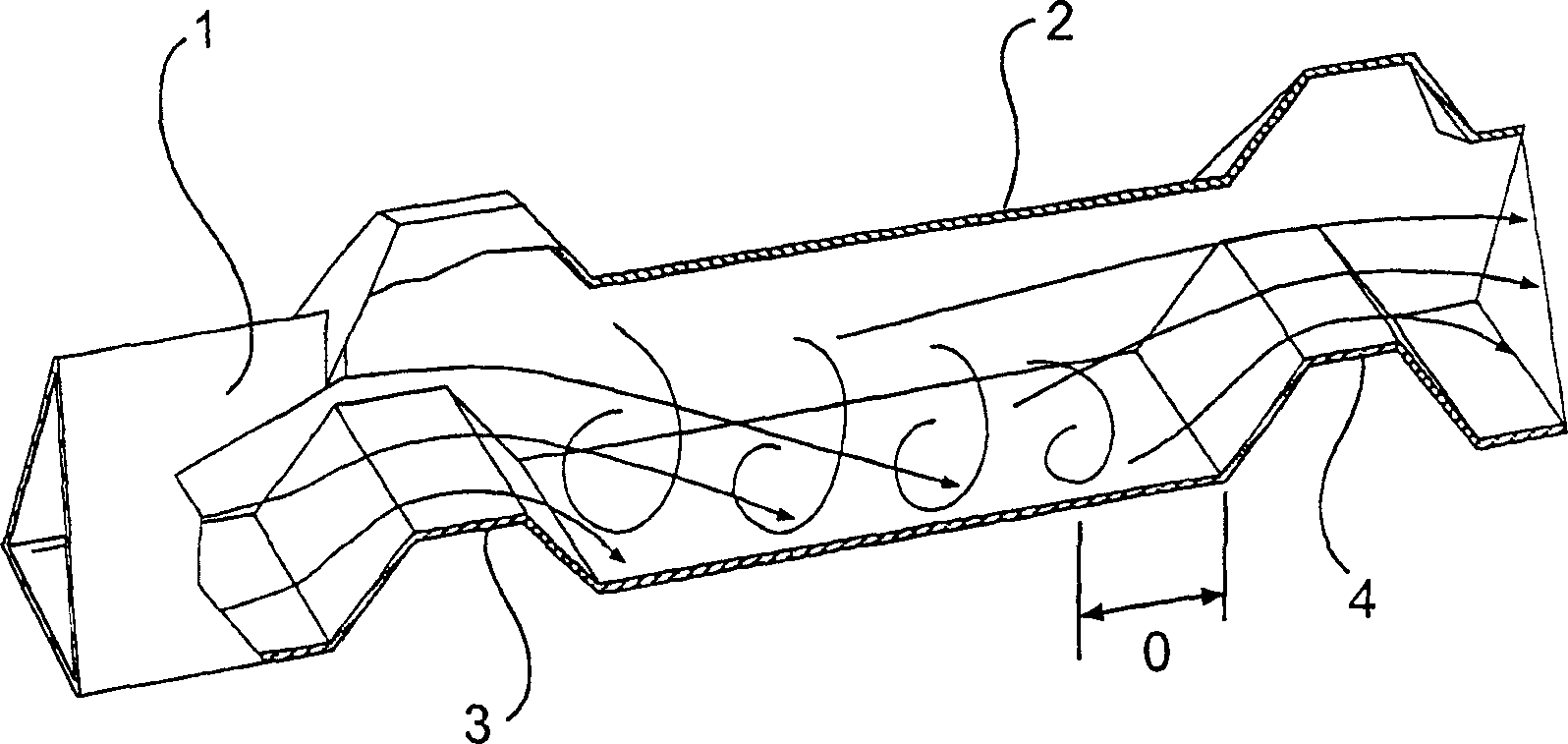

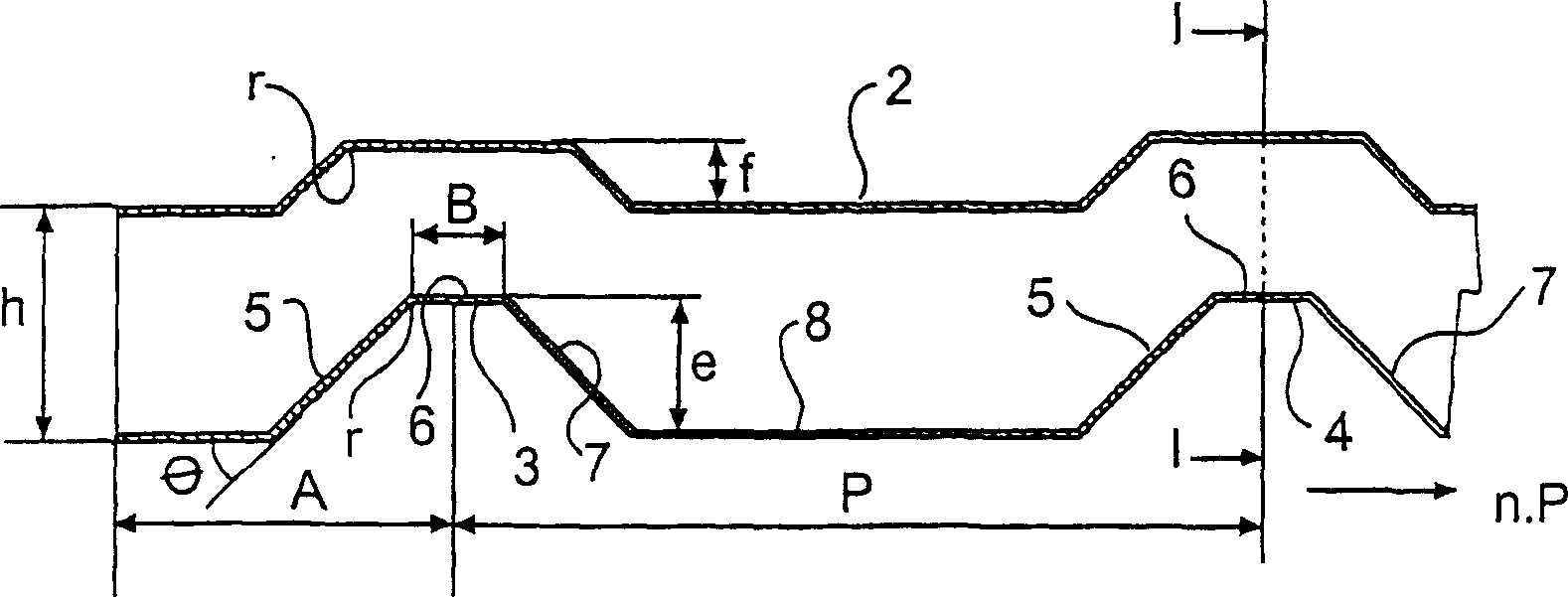

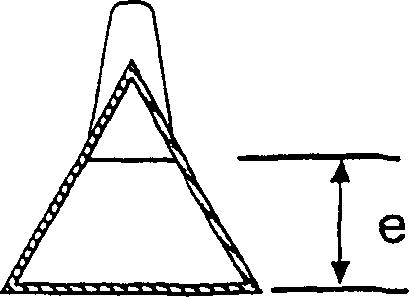

[0020] figure 1 and figure 2 The inlet 1 and a part of the piping 2 of the heat / moisture exchange device of the present invention are shown. In the figure, only the first turbulence generating device 3 and the second turbulence generating device 4 arranged closest to the inlet 1 are shown. The height of pipe 2 is h. The distance A between the open inlet and the center of the first turbulence generator 3 is determined by the ratio of the distance A to the product of the diameter of the turbulence and the Reynolds number which must be between 0.01-0.04. Here the turbulence diameter represents the ratio of the cross-sectional area of the fluid pipe to the circumference of the pipe cross-section, and the Reynolds number is determined by the air flow.

[0021] It also follows from the above that A depends on the Reynolds number and thus on the gas flow velocity. Therefore, the optimal placement of the first turbulence generating device depends on the operating environment at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com