Hand operated spray

A technology of injectors and nozzles, applied in the field of manual injectors, which can solve the problems of reducing the rotation of the swirl mechanism and product leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

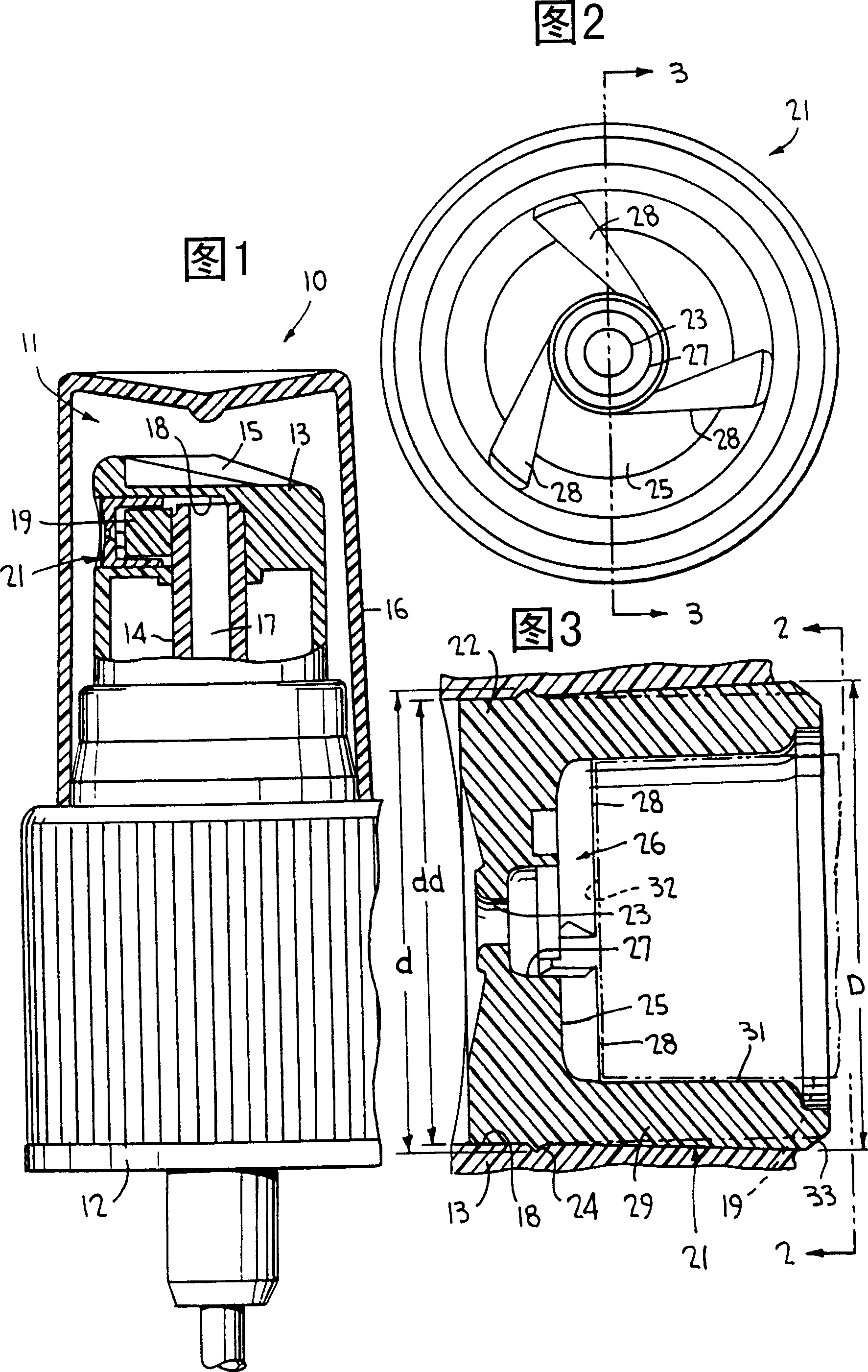

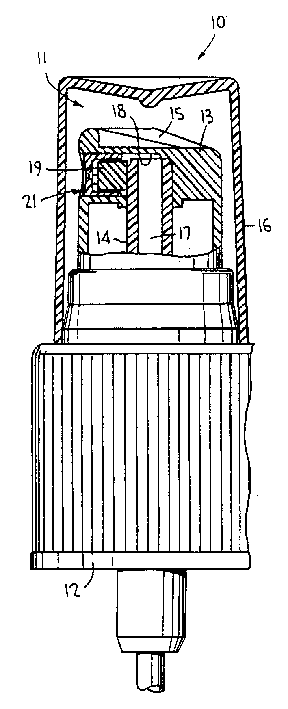

[0013] Reference is now made to the drawings, wherein like reference numerals indicate like and corresponding parts throughout the several drawings. The manual sprayer, indicated generally at 10 in Figure 1, is a pump sprayer of the type disclosed in US Pat. No. 4,051,983, which is incorporated herein by reference. Of course, other types of manual hand-held sprayers may also employ the present invention, such as trigger-actuated pump sprayers, aerosol sprayers, squeeze bottle sprayers, and the like.

[0014] The sprayer 10 has a body part 11 which includes a cap 12 for mounting the sprayer on a container (not shown) of the product to be sprayed. The body part also includes a plunger head 13 mounted on a hollow plunger rod 14 having features that can be moved in a manner known in the art when external finger pressure is applied to the top 15 of the plunger head. A pump piston (not shown) reciprocates within a cylinder (not shown). Of course, the top cap 16 is first removed by...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap